Metal welding and brazing are two reliable metal joint techniques. We, manufacturers, use these methods in different manufacturing processes for creating strong and durable joints among metal parts. Both of these are good solutions for making long-lasting joints in different applications. Though both of them serve the same purpose still they have some significant differences, knowing them will help you select the right one for your manufacturing process.

What is a Welding Method?

Sheet metal welding services, method of joining two or more metal parts together. To join them, we give the metals a high temperature or create pressure on them. Sometimes we apply hit and pressure both together on the metal parts to melt and fuse them together. This process can be done with or without filler materials.

First, we need to prepare the material for starting the welding process. And then we need to create the joint designs. After designing it we will start our welding process. Normally welding requires a higher temperature than brazing. Approximately 6,000°F (3,300°C) to 10,000°F (5,500°C) temperature is used to create weld joints. However, the temperature can vary depending on the materials and the kind of welding method we are using. After finishing the process, we will let weld joints cool so the joint among metal parts becomes permanent and long-lasting.

Welding is normally used in industries where you need more strong and reliable equipment like automotive, aerospace, shipbuilding, and manufacturing.

What is a Brazing Method?

Brazing is another reliable process for joining two or metal parts together. In the brazing process, for joining the metals we need to use a filler metal in the joint part. In this process, filler metal sets into a lower melting point than the base metal points. Doing this helps filler metal flow into the joining without doing any harm to the base metal. The filler metal we choose to create the braze joints is dependent on the base metals.

For creating braze joints, we must use lower temperatures than the welding process. Normally we use 1,100°F (595°C) to 1,600°F (870°C) temperature for melting metal parts in brazing. But this range can vary depending on the filler metal. With the temperature, we also need to control the heat process so it can’t damage the base metal.

One of the top advantages of using the brazing process is it can join two different materials together. It's also a good option for leak-tight material joints. The brazing process is a good joining option for complex designs, thin-walled materials and also on materials where we can’t do welding.

Difference Between Brazing and Welding

Brazing and welding both of them are effective techniques for joining metal parts. Both of these techniques are capable of creating strong and durable metal joints. But both of them have many differences and are suitable for different applications. To select the right metal joining process, we must understand their differences.

Here are a few factors that can highlight the differences between them.

Temperature Difference

The biggest difference between the welding and brazing process is the temperature. In the welding process, we have to use a high temperature normally more than 1,600°F to melt the base metal and fuse the metals together. But in the brazing process, we can’t use high temperatures. Because in this process we don’t melt the base metal. Instead of the base metal, we melt the filler materials. Melting the filler materials needs a low temperature around 840°F and 1,200°F. Using low temperature during this procedure is essential so it doesn’t melt the base metal.

Joints Strength

Weld's joints are stronger compared to braze joints. Because when we conduct the welding process, we melt the materials at the joining point. As a result, the original metal mixed together and created a strong joint after solidification. The weld joint is stronger and more flexible than the parent materials.

On the other hand, in the brazing process, we don’t melt the original materials. We melt the filler material, called a brazing alloy. That’s why braze joints are not as strong and flexible as their parent materials. These metal joints are more rigid.

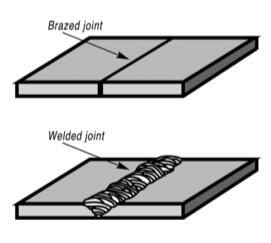

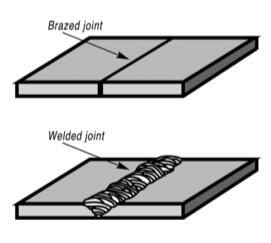

Appearance

Weld joints' appearance is more pleasing compared to braze joints. As we always don’t have to use filler materials in the welding process, the finished product looks smoother. But for that, we need to conduct the welding process carefully. Otherwise, the high temperature can discolour the weld joints.

In the brazing process, we have to use filler materials to create bonds between materials. That can leave a visible line or seam in a few pieces of equipment which do not look smooth. That’s why braze joints are not visually pleasing like weld joints.

Joint Types

The Welding process is used for making thicker metal joints. As welding melts the parent materials, this is more applicable for thicker materials. As welding can easily melt them with higher heat, weld joints also become solid, strong and thicker

In contrast, the brazing process is used for making thinner joints. In the brazing process, we melt thinner materials and dissimilar materials together with different melting points. So we use brazing on thinner and different materials so that they can stick together without melting the original materials.

Application Area

The Welding process is more suitable for applications where more strength and durability are required. Most of the time manufacturers choose welding for heavy machinery, structural applications and construction works. The brazing process is more applicable to electrical and electronic devices. Most of the time, manufacturers use brazing to join thin and delicate materials.

Skill and Equipment

The welding process requires more advanced equipment and skilful employees. For doing welding, we required welding equipment like welding machines and shielding glasses. With that, we also need to wear protective gear while working to protect ourselves. And we also can’t conduct the process without an expert.

But conducting brazing is quite simple, we don’t require advanced equipment or skilful employees for that. We will need only a few tools like a brazing torch and flux. We also don’t need to be an expert in the brazing process.

Advantages of the Brazing Process

The brazing process needs a lower temperature to melt the materials as a result it prevents the damage and distortion of the materials and the finished products. As most of the time we do brazing on thin materials, lower temperatures save their properties and qualities.

Through brazing, we can join two different materials together which we can’t do through welding. We can join brass, copper or aluminum together by using the brazing process.

As we use filler materials for creating braze joints, it doesn’t damage the electrical conductivity of the original materials. As a result, the electrical conductivity in the braze joints is also good. This quality makes them a suitable choice for electrical and electronic parts

Repairing braze joints is easier compared to a weld joint. Because for repairing these material joints, we don’t need to melt the whole thing. We can just melt and remove the braze joints and repair it.

Advantages of the Welding process

The top advantage of weld joints is their strength. These joints are strong and durable and that makes them the first choice for any heavy and structural applications that need strong material joints for flexible operations.

Weld joints are long-lasting as they are created by melting the original materials. As a result, they become a solid and durable part of the material. It can’t be easily cracked or broken.

Some weld joints can also be air and water-tight. That means we use them for applications that need to be worked under liquid or gas pressure.

They are also aesthetically pleasing. Weld's joints don’t don’t have any visible lines and also look smoother.

The welding process is more efficient than brazing. Because of its advanced equipment and technology, it can do complex projects easily within a short time

Wrapping Up

Welding and brazing are two effective methods for joining metal parts. Though their purpose is the same, creating metal joints, their application and process are different. Both of these metal joint techniques have their unique advantage. However, they can’t be used in the same kind of application. We must select the one that will fulfill our application needs. But understanding the difference between brazing and welding will definitely help to make the right choice.