Every business is affected by cost. The lower the cost, the higher the profits will be. Are you looking for a new business venture or a way to cut down laser-cutting costs? Perhaps you are new to the laser-cutting business and want to know more about the use of laser to cut steel or how to calculate the cost efficiently. Well, we are here for you. Our article is a one-stop solution for any questions and queries regarding laser cutting. We will guide you from machine prices to cost cut-down.

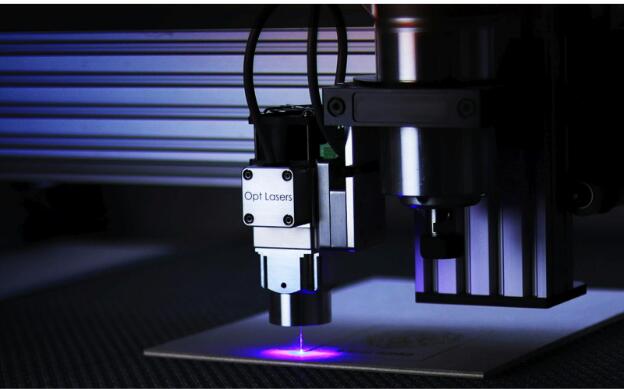

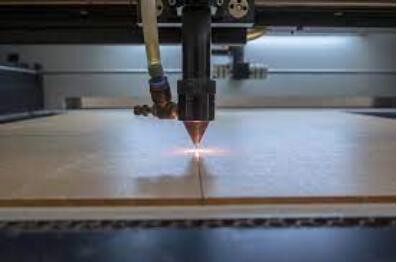

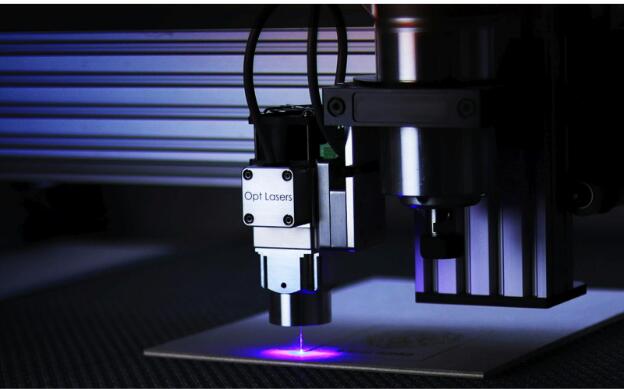

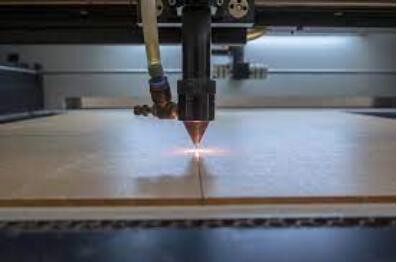

What is a Laser Cutting Machine?

A laser-cutting machine vaporises, burns, or melts a material to achieve a certain design. They were predominantly used by large manufacturers, but hobbyists can now use smaller versions.

What is the Cost of a Laser Cutting Machine?

The cost of a laser cutting machine hugely varies- do you want to use it for large-scale manufacturing for a small business or even as a hobby?

On average, the cost of laser-cutting machines can range between $1000 to $1000000. It largely boils down to what kind of laser for cutting steel you want to buy. CO2 laser machines start at $2000. Meanwhile, fibre laser cutting machines can cost more, with around $30000 as the startup cost. Diodes, on the other hand, fall on the cheaper side, with a starting cost of $350, but diodes are used for wood and cannot be used on steel. They are also suited better for hobbyists.

Factors to Consider for Buying a Laser Cutting Machine

The type of machine

There are two types of machines to choose for steel-cutting: CO2 and fibre lasers. Both of them are good at what they do but have different advantages and disadvantages. Here below, are the advantages and disadvantages of each.

Fibre Laser Cutter | CO2 Laser Cutter |

They are more efficient laser-cutting machines. Fibre laser cutters between 0.5-12kW can easily cut steel with less energy. More cost-effective, consuming approximately between $1350-$2700 in a financial year. The energy efficiency is between 20-35%. More versatile. It allows for metal cutting, metal engraving, non-metal engraving, metal clearing and metal marking. Best for large businesses due to the high capital cost.

| Not as efficient or precise as fibre laser-cutting machines. CO2 lasers require between $19350-$38700 in a financial year, making them more expensive to operate. The energy efficiency is also terrible as it is only between 5-10%. Not as versatile. It can only be metal cutting, engraving and non-metal cutting. Well-suited for smaller businesses since it is cheaper.

|

Axes

Are you a big firm that needs to produce tons of work and that too quickly? Then, a bigger, more expensive machine will give you better laser-cutting designs. More axes means more lasers that will aid in cutting the piece. Thus, customers will be happy since all the pieces will come out without flaws.

The extra axes will finish the work quickly, which will also save machine running costs. So now, more pieces can be produced in less time.

Brand

Whether you choose CO2 or fibre as your machine, you will have to do extensive research about the right brand for your business. That includes looking into the brand’s history, its quality, the range of steel-cutting laser machines available, and the prices.

How to Calculate Laser Cutting Cost

To calculate the average cost of your laser-cutting machine, you need to jot down some of the basic expenses incurred to create a suitable quotation or estimate the expense of getting into the metal-cutting expense. They are:

Machine Running Time

The title is self-explanatory, and machine running time is the cost of running the machine, which includes pure machine time, too. Generally, this will cost approximately $1 per minute. The longer your machine spends cutting steel, the more the machine's running time will be. It is better to lower machine running time (if possible) to cut down average costs.

Set up Time

If your laser machine is cutting up several pieces of different sizes, then there is a set-up time which needs to be taken into account too. Usually, the more designs you have of varying sizes and intricacies, the more set-up time your machine needs.

Design Complexity

If a design is more intricate, it will need more steel, more machine running and set up time, as well as more gas (if you are using CO2 laser)- all of which will inevitably increase laser cutting charges.

Moreover, more complex designs require the machine to spend more time on a piece and use more power than an easy one.

Labour

You will most likely need to use labour, even if it is a CNC machine. This will increase costs. Labour costs vary from state to state and country to country and even depend on how many people are working.

If you are using a CNC CAD/ CAM machine, then you will only need one operator.

(To calculate how much of the labour is on the machine, multiply the labourer’s hourly wage by the amount of time spent on the machine.)

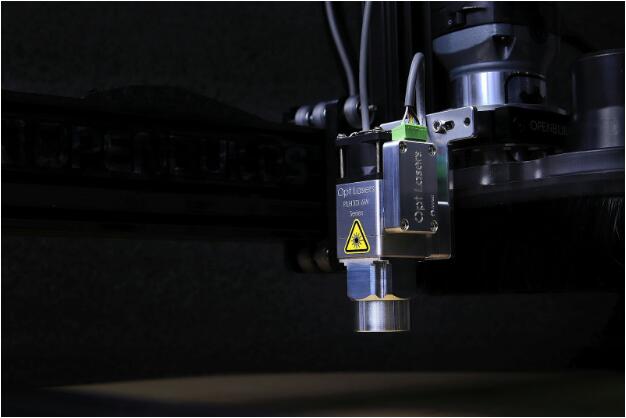

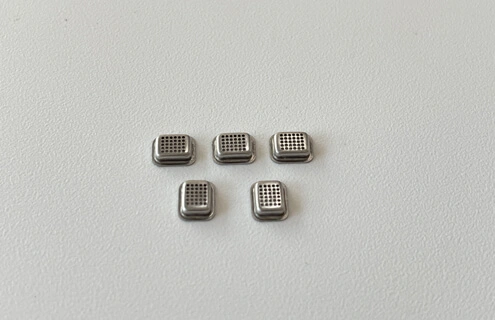

Consumable Parts

Consumable parts refer to the nozzle, protective lens, and ceramics that the laser cutting company will use for the production process. Nozzles help to push out the oxygen/ gas that will be used. The protective lens helps the laser beams to focus on a particular area so that cutting can be smooth and precise. These pieces also need to be replaced more frequently than other parts, hence the term “consumable”.

Apart from these, other consumable parts, such as mirrors and cooling systems, are used for the lasers. These non-current assets depreciate quickly and need to be replaced frequently. The mirrors help to reflect and focus the laser beams, while coolings, like water coolers, keep the entire thing cool enough to function and prevent overheating.

Other Overhead Expenses

You will also have to consider maintenance costs, depreciation, insurance, and any other overhead expenses used in order to calculate the correct laser-cutting cost.

How to Reduce Costs

Reduce Wastage

Reducing the wastage of the material used will lead to greater output with less input. You can implement TQM or kaizen to reduce wastage, which will ultimately increase profits, too. Installing better laser-cutting machines will improve accuracy and precision and will also reduce costs.

Software Upgrade

A CNC and CAD/CAM laser-cutting machine will reduce the need for human labour (except the operator), which will cut down costs. Plus, they are faster and more efficient but also require more power.

Batch Production

In order to implement batch production, you will need to take in similar orders. This means that the machine setup time is now reduced to little to no, which will hugely save costs.

As the products produced are similar, there will also be reduced wastage due to repetition.

Hire Experienced Workers

Experienced workers are more efficient. For example, a more experienced operator will be able to operate the laser machine with more accuracy, putting in the correct measurements, which will save time and resources, compared to a less-experienced worker.

Conclusion

We have provided you with everything you need to know about steel laser cutting. The laser cutting industry is a blooming one, and we wish you the best in your future business endeavours.