How does sheet metal size work?

Sheet metal is the most used form of metal for manufacturing and fabrication processes. There are hundreds of thousands of products that are manufactured from sheet metal.

The term sheet metal size seems to be simple and self explanatory but there are different ways to present a sheet metal size in different parts of the world.

Inches and millimeters from imperial and metric systems respectively are mostly used in word to measure sheet metal thickness. Inches systems are mostly used in the United States of America USA while the rest of the world mostly used millimeters “mm” from metric systems.

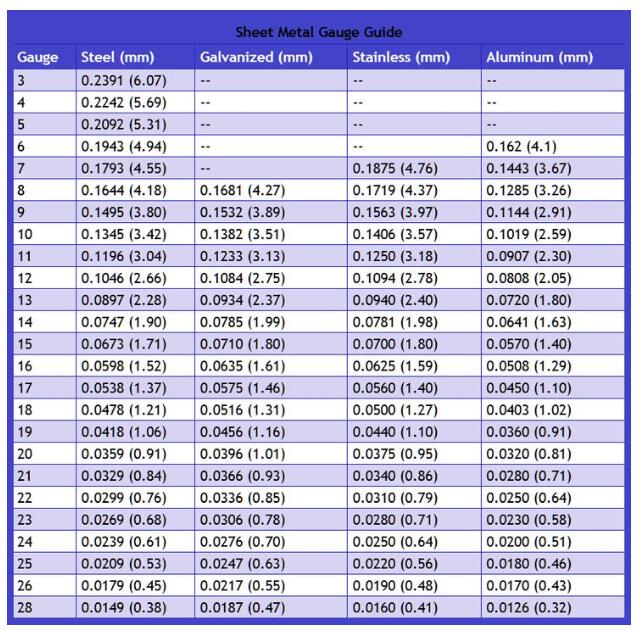

There is another measuring system that is used in the entire world to measure and label the sheet metal thickness and that is the gauge system. Now There is no standard way of marking sheet metal in gauges.

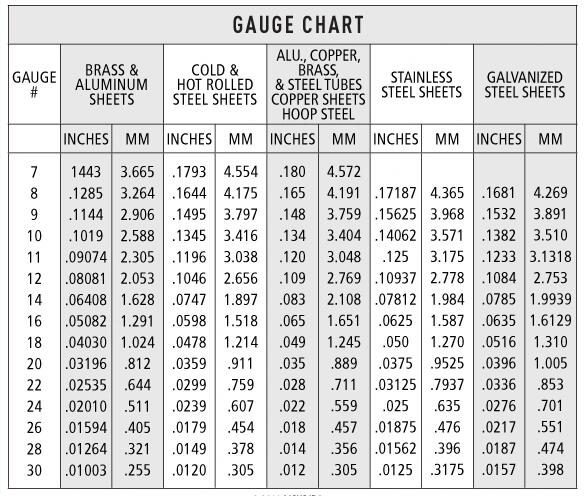

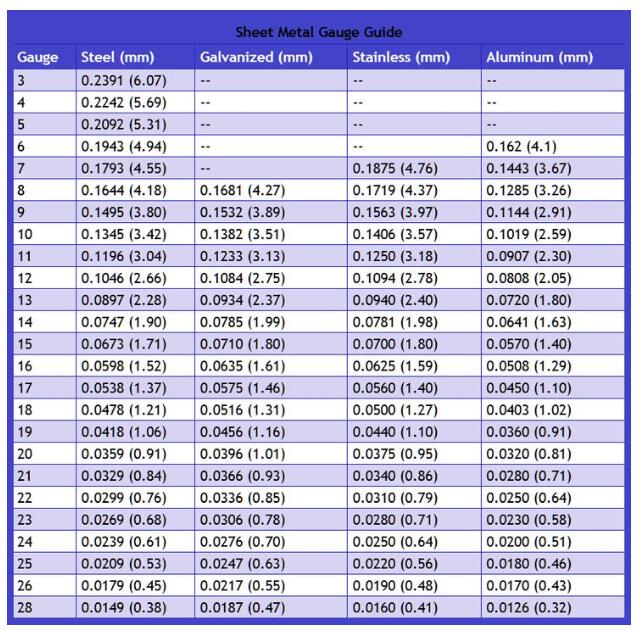

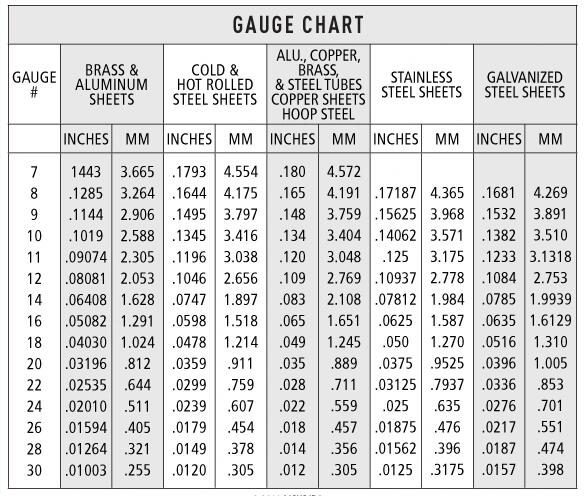

There are several sheet metal thickness charts and sheet metal gauge charts that convert sheet thickness from inches and millimeters into gauges.

Standard sheet metal thickness

There is no single sheet metal gauge chart that can show the relation between inches or millimeters with gauge value. Rather there are separate individual charts for each material.

Mean for steel sheet thickness there is a separate chart that converts inches or millimeter value to steel gauge thickness. Similarly there are separate charts for aluminum, galvanized steel, stainless steel, brass, copper, and mild steel.

There is no guarantee that a particular manufacturer can deliver your required gauge size and materials. Different manufacturers prefer to produce their own demanded gauge size and this may vary a lot from region to region.

How To Choose The Right Sheet Metal Size For Your Project?

Consider your product design, tolerance and Size

The process of selecting the right sheet metal size for your project starts with the consideration of your product design and the tolerances. Here are some ideas from JCLDD sheet metal fabrication manufacturer about deep draw manufacturing, The reason why it's a first factor to consider is that it's not possible to shape and get required tolerance from all sheet metals.

The design and complexity of shape will define which sheet metal option can be used for its manufacturing. Different product design factors that may be involved in sheet metal selection are

Design complexity of your product.

Wall thickness needed for the product

Bend allowance need for specific features

K-factor

Slots and holes orientation

Based on the design and tolerance, the only dimension important here is the thickness of the sheet metal. Sheet metal thickness is the most important factor here rather than the length and width of the sheet.

You might need to refer to sheet metal gauge charts or more specific for example steel sheet metal gauge charts to understand the sheet metal thickness. The thickness of the sheet controls the factors like bend radius during bending and metal stamping. It also plays an important role defining the sharp features of the design.

Finalize the required material

Based on the product working and use, there will be certain material requirements that the selected sheet metal needs to fulfill. These may include material density, strength, strength to weight ratio, material color, texture, tensile strength, ductility, mealiability and material stiffness.

Your product may need any combination of the above mentioned properties and there will be a specific range for each of those values that your product needs. There is a possibility that more than one material will be quality for the application. In this case most projects rely on the cost effectiveness of the product and select the materials with least cost.

Check the alloy options

There is a good chance that you might need to check the alloy options for any material you short list. Just for example, if you select aluminum to work with, then you will be working with one of many alloys available as pure aluminum sheet metal is neither strong enough nor easily available in sheet metal.

Similarly if you want to work with any steel sheet thickness then you might consider stainless steel or galvanized steel to get high corrosion resistance with the same strength and density.

So do consider alloy options for a better material selection. You also need to consider two to three materials or alloys at the same time for further filtering them during the selection process.

Consider manufacturing processes involve

It is important to consider the manufacturing process that will be involved during the sheet metal size and material selection. As your product and industrial metal stamping, will need a number of sheet metal fabrication processes like sheet metal cutting, sheet metal bending, sheet metal stamping, water jet cutting, laser cutting and punching.

Your product might also need several joining processes like sheet metal welding (TIG welding, MIG welding, arc or gas welding), brazing, soldering or temporary joining using nuts and bolts.

It's important to consider all those manufacturing processes that will be involved in product manufacturing based on the initial product design. For example some materials and sheet metal sizes like aluminum cannot be welded easily whereas mild steel can be welded very easily and you might need soldering and brazing for copper and brass.

Consider the surface finishing and post processing

Last thing to consider here is the surface finish and post processing required by the product. All materials and sheet metal sizes cannot deliver required surface finish or they cannot be processed for the required post processing.

You need to consider any surface finish required like paint, polishing or custom surface finish texture. Similarly any post processing required like annealing, quenching or tempering required to improve final product strength, corrosion and wear resistance can affect sheet metal size and material selection.

Conclusion

Selecting sheet metal size for your product is not just selecting the steel gauge thickness. It’s about selecting the right material with the right size. You will need to consider product design, tolerances, size, material properties, manufacturing process, final surface finish and any post processing required to select the best material for your product.