Standard and Custom Machinery

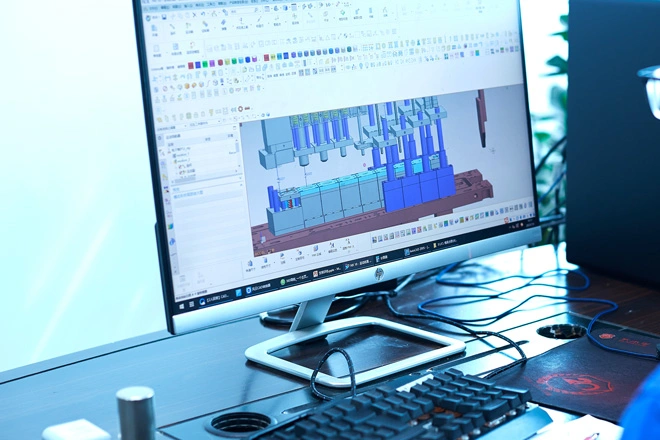

JCL owns state-of-the-art machinery and commitment to delivering exceptional metal stamping solutions. With over 50 presses in the production floor, JCL offers a diverse capabilities to meet the specific needs of press stroke. Here are the different press machines at the factory, highlighting their key features and tonnages.

Pneumatic Press— 25 to 200 tons

Open Back Inclined mechanical presses— 22 to 200 tons

Mechanical, double action presses — 22 to 200 tons

High precision presses, C-Frame double crank — 3 to 500 tons

Straight side press — 60 to 500 tons

Press-driven roll feeder

Automated loading & unloading robotic arm

Comparison of Deep Drawing Press Machine in Different Driven Power

Mechanical Press | Pneumatic Press | Hydraulic Press |

Low Cost for Initial Setup | High Punch Speed | High Tonnage Available |

Easy to Maintain | Relatively Low Cost to Purchase | Less Maintenance with Load Protection |

Fast Operation in Single Maximum Punch | Easy to Use | Compact with Less Space Needed |

Consistency in Simple Action | Sufficient Power Source | Precise for Complex Forming |

We work closely to guarantee that our press machines maintain consistent accuracy and precision. By regularly calibrating our equipment, we can offer our customers superior stamped products that meet their exact specifications. Furthermore, we continually invest in the latest press machine technologies to focus the technologies on the edge.

The Process of Deep Drawing in Hydraulic Press

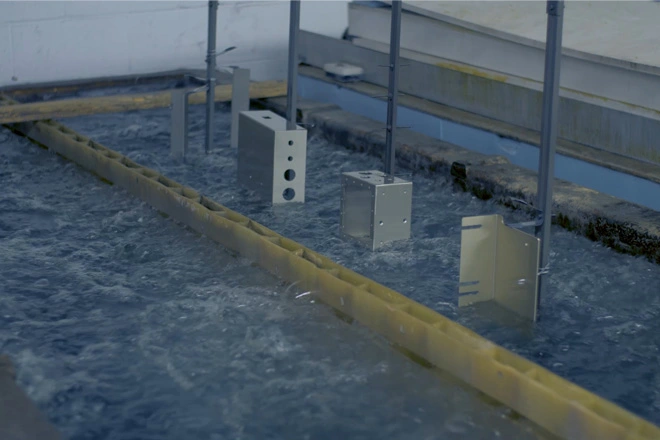

Deep drawing is a sophisticated metal forming process that involves transforming a flat sheet of metal into a three-dimensional shape using a hydraulic press. This process is widely used in various industries, including automotive, aerospace, and consumer goods, due to its ability to produce complex shapes with high precision and consistency.

The deep drawing steels process begins with a metal blank, typically made of materials such as aluminum, stainless steel, or copper. This blank is placed over a die cavity, which is shaped according to the desired final product. A hydraulic press then applies a controlled force to a punch, which pushes the metal blank into the die cavity. The hydraulic press is particularly advantageous in this process because it provides a consistent and adjustable force, ensuring uniform deformation of the metal.

As the punch descends, the metal blank undergoes plastic deformation, stretching and flowing into the die cavity to take on its shape. The hydraulic press’s ability to maintain a steady force throughout the process is crucial in preventing defects such as wrinkling, tearing, or thinning of the material. Additionally, the use of lubricants during the process reduces friction and further minimizes the risk of defects.

Once the metal has been fully drawn into the die cavity, the punch is retracted, and the formed part is removed. The result is a seamless, high-quality component with precise dimensions and excellent surface finish. The deep drawing process in a hydraulic press is highly efficient and capable of producing large quantities of parts with consistent quality, making it an essential technique in modern manufacturing.

The Difference Between Deep Drawing and Press Forming

Deep drawing and press forming are both essential metal forming techniques used in manufacturing, but they serve different purposes and involve distinct processes. Understanding the differences between these two methods is crucial for selecting the appropriate technique for specific applications.

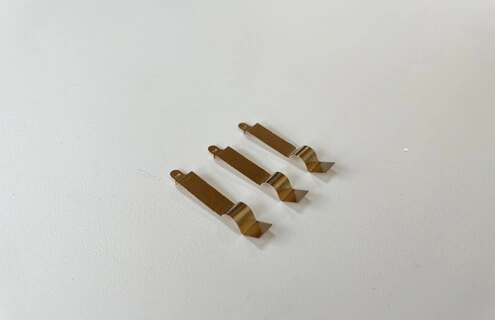

Deep drawing is a process that transforms a flat sheet of metal into a three-dimensional shape with significant depth, such as a cup, can, or automotive component. This process involves placing a metal blank over a die cavity and using a punch to push the metal into the cavity, creating a deep, hollow shape. The key characteristic of deep drawing is the significant depth-to-diameter ratio it achieves, making it ideal for producing parts with substantial depth and intricate geometries.

On the other hand, press forming, also known as stamping or pressing, is a broader term that encompasses various metal forming techniques, including bending, flanging, and coining. Press forming typically involves shaping a metal sheet by applying force through a press, but it does not necessarily achieve the same depth as deep drawing. Instead, press forming is used to create a wide range of shapes and features, such as bends, flanges, and shallow contours, often in a single operation.

One of the primary differences between deep drawing and press forming is the type of force applied and the resulting deformation. Deep drawing requires a controlled, consistent force to achieve the deep, hollow shapes, while press forming can involve various types of forces, such as compressive, tensile, or shear, to create different features. Additionally, deep drawing often requires multiple stages and precise control to prevent defects, whereas press forming can be a quicker, single-stage process.

In summary, while both deep drawing and press forming are vital metal forming techniques, they serve different purposes and involve distinct processes. Deep drawing is ideal for creating deep, hollow shapes with high precision, while press forming is more versatile, capable of producing a wide range of shapes and features in a single operation.