Metal stamping is a versatile manufacturing process that shapes coils or metal sheets or into a variety of desired forms with precise punches and dies. From complex car parts to essential home machines, this cycle is utilized to make a large number of parts and items. A metal sheet is first situated between the punch and die, and power is then used to shape the material into the necessary shape. For mass assembling in businesses and organizations that need exact, precise and predictable metal parts, metal stamping is a prescribed choice because of its benefits in speed, cost-viability, and high accuracy. Metal stamping is a crucial step in the production of a wide range of goods, whether it is used to create intricate geometries or huge quantities of parts with similar shapes.

How Metal Punching Started?

Here are some ideas from JCLDD sheet metal fabrication manufacturer about deep draw manufacturing.

The seemingly straightforward process of precisely punching holes into metal sheets has a long and complicated history that is intertwined with technological development and human creativity. Set aside some margin to get knowledge and observe the advancement of this progressive strategy, from its unobtrusive beginnings to the cutting edge innovative wonders.

Ancient Echoes Phase

Our predecessors were most likely antiquated metalworkers who beat and etched straightforward openings in sheets of copper, silver, and gold. These valuable metals were molded into trimmings, instruments, and, surprisingly, unrefined defensive layer because of their pliability and excellence.Suppose, the deft hands making perfect gems out of small gold leaves, each opening a showing of their creativity and responsibility.

Invention of Hammer & Die

Metalworking strategies polished with civilizations passed. And metalworking was changed with the approach of the basic blend of die and hammer. Metalworkers put a metal sheet between the die and hammer and a perfect, careful hole was made when the hammer struck the die. This technique has been used to create a wide variety of metal crafts throughout history, including ornate tinware used in colonial kitchens and the elaborate armor worn by medieval knights.

The Surge of Industrial Revolution in 18th Century

In the 18th and 19th centuries, metal punching was just one of many growing industries. A major step in the right direction was made in the late eighteenth hundred years with the formation of the punch press. This gadget could poke a few holes immediately with astonishing velocity and exactness when controlled by steam or water. This made it conceivable to deliver metal things in enormous amounts, for example, home devices and vehicle bodies.

Modern Marvels

A new, modern time of metal punching has started. With the utilization of lasers or CNC programming, PC controlled punching machines can exactly make openings of any size or shape. These gadgets, which are utilized in the development and aviation ventures, are the workhorses of contemporary metalworking.

2. What is Metal Punching?

Metal punching is a cycle wherein you utilize exceptional instruments to make openings, shapes, and spaces on metal pieces. In metal punching, you cut a piece of metal utilizing areas of strength. Besides, you can punch various sorts of metals, like steel, iron, copper, and aluminum. Each metal has its own solidarity and necessitates the perfect proportion of strain to punch with next to no defect. You can do it manually or with a machine. Making parts for some things, similar to adornments for airplanes is frequently utilized.

3. Steps To Process The Metal Punching

Albeit metal punching can be an interesting and satisfying activity for various applications and industrial metal stamping, it's vital to move toward it cautiously and with the right strategy. A layout of these steps is included.

Note: In light of the venture, the request for these means might change a bit. However, by and large, most ventures, including metal punching, will follow these six stages.

1. Plan Your Marking Location

Point a location and use an indelible marker or pen mark where you want openings will be on the particular position on the metal sheet. To ensure accuracy and spacing, utilize a format, ruler, or different devices.

2. Designing Layout

Secondly, after finishing the marking location, you need to design the holes shape and accuracy. When you complete the design, the time has come to bore the pilot holes or mallet the pilot spaces into the piece of metal to direct the punches.

3. Punching

Now it is time to use dies along with other sheet metal punch tool to draw the openings, as per the way you have chosen. If you consider the use of hand tools then you need to moderate power and maintain hand stability. While utilizing a machine, give close consideration to the working manual.

4. Deburring

Utilizing a file or deburring device, eliminates any burrs or sharp edges from the metal after the openings have been punched. Subsequently, the eventual outcome is both more secure and all the more outwardly lovely. This step we call — deburring.

5. Inspection

After deburring, you need to audit the metal part of assurance that it meets every one of the essentials and necessities of your client's task.

6. Cleaning

Presently the last step you will perform is the metal piece cleanance by eliminating all buildups and flotsam of extra metal punching.

4. Which Machines Are Used For Metal Punching

There are various kinds of punching machines, yet because of the different primary guidelines, the expense and handling effects will change in like manner. Obviously, without a doubt, for particular sorts of presses, there's generally a shared trait inside the synthesis of the construction. Typically, a punch press machine is utilized for metal punching.

Furthermore, a punch press could seem essential toward the start; however, it's a perplexing structure made out of different parts cooperating. Two kinds of metal punching machines are utilized these days: manual metal punching and programmed metal punching machines. How about we make sense of the two terms exhaustively?

Manual Metal Punching Machine Vs Automatic Metal Punching Machine

With regards to proficiency and activity, manual and programmed metal punching machines are at the far edges of the range. The administrator of a manual punching machine should physically take care of the metal sheet into the gadget and draw in the punching system. Manual punching machines are normally fueled by human work.

These gadgets are proper for prototyping, studios, and more limited-size exercises with lower creation numbers. Even though manual machines are not difficult to utilize and sensibly evaluate, they could take more time to finish an activity, which would diminish their adequacy for huge scope fabrication.

On the other hand, more robotization and accuracy are presented via programmed metal punching machines, which are much of the time fitted with computer numerical control (CNC) innovation. Without consistent human association, these gadgets are equipped to handle metal sheets ceaselessly. Automatic control, made conceivable by CNC frameworks, makes it conceivable to make perplexing and exact shapes with little arrangement in the middle between creation runs.

Programmed punching machines work successfully in huge-scope modern settings where taking care of messy designs, speed, and consistency are fundamental. Even though their underlying venture is costly, their superior efficiency and productivity make them the better choice for areas that need to create punched metal parts in massive amounts.

Parts of Metal Punching Machine

Technical Parameters of Metal Punching Machines

Tonnage

Power source

Material thickness

Hole size

Punching speed

Repeatability

Stroke length

Number of stations

5. Metals Used for Punching?

Metal punching is an adaptable method for molding various types of metals. The metal you decide for punching relies upon what is required for the job. Here are a few sorts of metals that are typically utilized for punching.

1. Use of Steel or Stainless Steel

Since materials like steel or stainless steel are extremely hard, thus, when you punch them, it's essential to utilize sufficient power to finish the cycle. In any case, only a few of them can make them break.

2. Use of Iron

As you know iron is a very strong metal to break. You can't play out the punch cycle on iron in a simple manner. In this way, it is hard to punch since it doesn't spread without any problem.

3. Use of Aluminum

As you most likely are aware, aluminum is a pliable metal. In this way, you can twist aluminum more effectively than iron and steel. What you really want to do is cautiously plan and program the metal punching interaction to accomplish the best outcome.

4. Use of Copper Metal Punching

While punching copper, you should be exceptionally cautious about breaking pressure. Since, in such a case that it breaks, it will isolate the parts. It means a lot to utilize exceptional blocks to prevent the copper from changing shape and to keep sharp edges or inconsistencies from framing.

6. How to Use Punching in Metal Stamping?

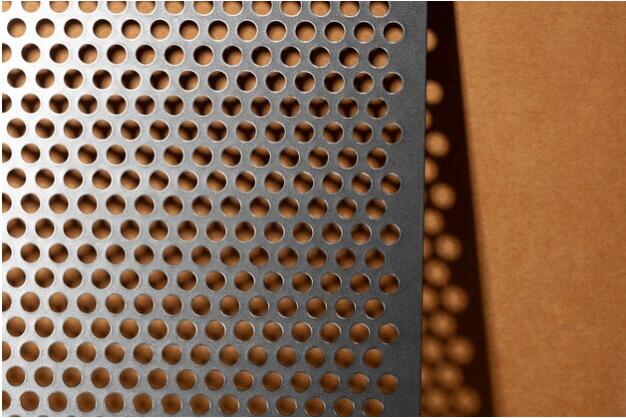

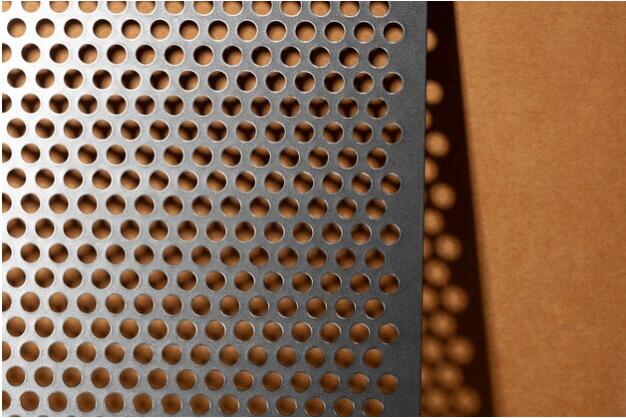

Punching is a fundamental stage in forming and characterizing the completed metal stepping item. Punches dispose of material that isn't required, abandoning precise openings, structures, and fine elements, similar as a gifted stone carver would. On account of the managed power and precision of this versatile cycle, picture elaborate stuff teeth cut by punches, decorative examples emblazoned on adornments, or ventilation openings punched in car parts. In this way, punching fills in as a groundbreaking craftsman, giving level metal sheets life and usefulness with its deft touch.

The improvement business utilizes punching inside the creation of fundamental parts like sections, sheets for cladding and material, and central air parts. The remedial business, besides utilizes punching as a part of the manufacturing groundwork for parts in helpful equipment, furniture, and restorative stuff nooks.

7. Pros of Metal Punching

Metal punching has a lot of benefits, and underneath are a portion of the many.

Punching is one of the most conservative ways of punching holes or shapes into sheet metal, making it an alluring choice for large-scale manufacturing contrasted with laser cutting, waterjet cutting, and so on.

Punching offers steady repeatability, which makes it ideal for creation runs.

It is profoundly exact, making it ideal for businesses that need tight resilience

Being a computerized interaction, it works rapidly, which makes it exceptionally proficient.

It is utilized on an extensive variety of sheet metals, which makes it reasonable for different applications.

8. Disadvantages of the Metal Punching Method

Very much like some other assembling process, metal punching accompanies its own disadvantages. Even though it has many advantages, it additionally has issues and limitations that you really want to consider.

It requires a sensible measure of investment to set up, and the expense of tooling is likewise high. This can make it over the top expensive for little orders or prototype model items.

It functions admirably with metals up to a particular thickness. Assuming the metal is extremely thick, punching may not function admirably or the punching machines and instruments might get broken down more rapidly. If the thickness of the metal is excessively high, punching may not be fitting, or the punching machine and devices might be dependent upon more prominent wear.

As you are aware, we use punching to simplify shapes or it turns out best for simple shapes. You really want custom or unique instruments for making more convoluted shapes, which makes creation more costly.

It can leave burrs or twisting on the edge of holes. To get a good final edge, this requires post-processing steps like deburring. This adds to creation expenses and time.

9. Applications of Metal Punching Machines

Metal punching machines are used in various industries. Below, we compile the list of industries that use it.

Sheet Metal Fabrication

Automotive Components

Aerospace Parts

Electrical Enclosures

Appliance Manufacturing

Metal Furniture Production

Electronic Devices

Architectural Elements

Signage and Lettering

Medical devices

Jewelry and Ornamental Metalwork

HVAC Components

Industrial Equipment PartsI

10. How Much Does a Metal Punching Machine Cost?

A punch machine's price can vary greatly depending on its features, capacity, and type. Generally speaking:

$500–5,000 for small, manual punch presses.

More features and in the midrange, from $10,000 to $50,000.

Above $100,000 for high-end, CNC, or industrial grade.

How Can JCL Be Your Reliable Partner?

We at JCLDD have been punching sheet metal for over 13 years. We invest wholeheartedly in running the most exact and valuable apparatus in the business, ensuring that the result you see is perfect and reliable.

We can finish a huge volume of work rapidly while not forfeiting quality. We complete it rapidly and masterfully.

We are focused on both remaining current and rehearsing this speciality. We have specialists in metal creation and laser cutting in our group. We work together with you as a partner, supporting you every step of the way. We guarantee that each project will produce a high-quality final product.

Kindly make sure to be in contact with us right now to study our creation administrations or email us. Our staff is glad to share their insight and assist you with getting punched up on the interaction!

Conclusive Remarks

To conclude, the expertise of metal punching includes utilizing exact power and cautious readiness to cut holes and structures out of metal sheets. An interaction transforms level sheets into convoluted structures and gives life to various ventures, from the wonderful smash of a hand punch to the musical murmur of a cutting edge machine.

The basic thought is dependably something very similar, even with various apparatuses and strategies: employ pressure to remove the undesirable material and leave behind the desired shape. Metalworkers use punching as a tool to express their imagination and achieve their goals. It can be used to make anything, from delicate jewelry with tiny holes to the tough chassis of a car made with strong tools.

Some FAQs

These are user intent-based questions that's why I compile these basic questions to insert throughout the article.

1. What kind of shapes can be punched?

Shapes that can be punched from metal sheets range from straightforward openings to extra multifaceted designs like square shapes, circles, squares, and, notably, custom crafts. Metal punching's adaptability allows for the formation of a wide range of shapes depending on the tooling used.

2. Can I punch metal at home?

While it is possible to punch metal at home using a manual punch or hydraulic, it is generally not proposed for the sake of security. Metal punching is a major area of strength for incorporating specific stuff, making it more sensible for present-day settings with the essential safety set-up.

3. What metals can be punched?

You can punch various kinds of metals like steel deep drawing, aluminum deep drawing, iron deep drawing, stainless steel deep drawing, and so forth. Which metal is best depends on the application and quality requirements of the finished product.

4. How much force does it take to punch metal?

The type, thickness, and multifaceted design of the state of the metal everything influences how much power is expected to punch it. Different materials and purposes can be obliged by the changed weights of punching machines that are accessible.

5. Is metal punching safe?

Safety must come first because metal punching requires sturdy equipment and cutting tools. To ensure a protected workplace, it is fundamental to follow safety strategies, wear individual insurance hardware, and get the essential preparation.

6. Where can I learn more about metal punching?

Besides JCL, you can gain knowledge about metal punching from Industry manuals, online tutorials, and vocational training programs.

7. What Is the Difference Between Punching and Stamping Metal Sheets?

Punching and stamping both involve molding metal sheets, however punching is more worried about making holes or cutouts, though stepping is more engaged with framing, twisting, bending and embossing.