Automotive industry

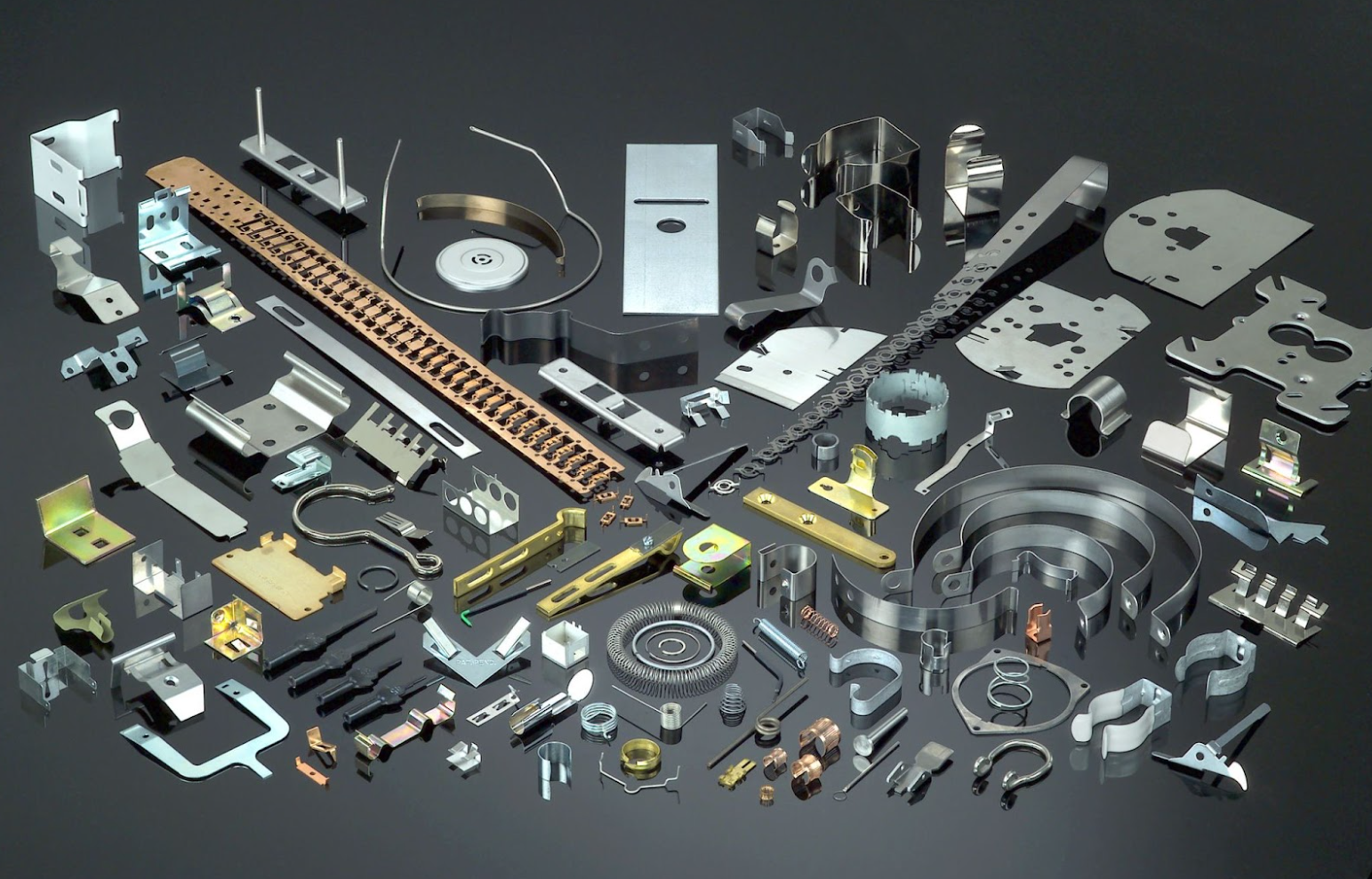

Body panels(hoods, doors, and fenders) ⇛ lightweight

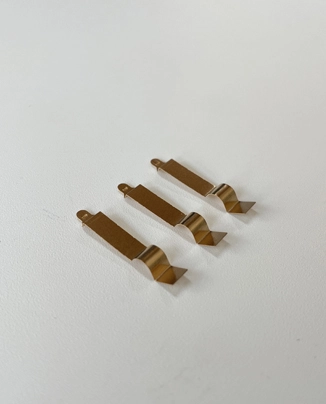

Chassis components(engine cradles, suspension arms, and brackets)⇛strength and corrosion

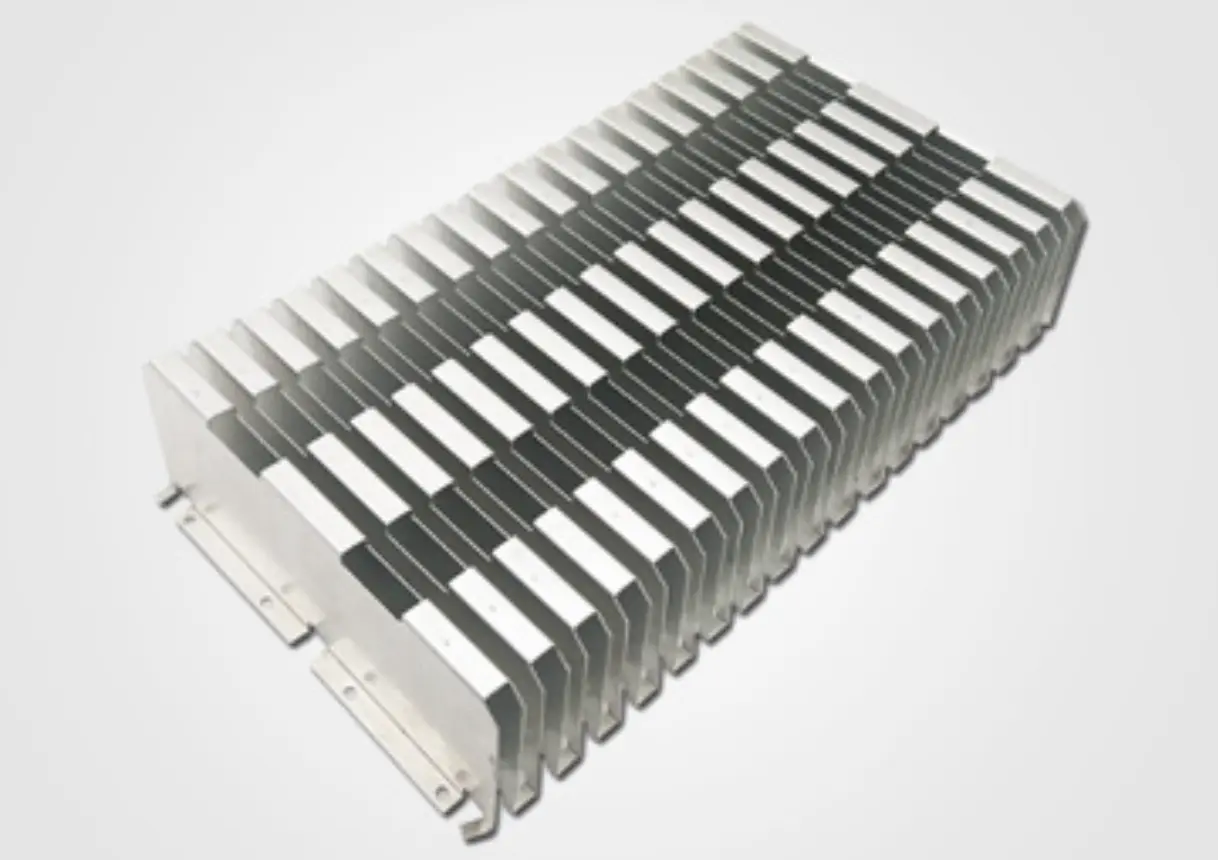

Radiator components (fins and tanks) ⇛ excellent heat transfer, lightweight

Aerospace industry

Aircraft fuselages and wings⇛ high strength-to-weight ratio and formability

Landing gear components(struts and wheels)⇛ lightweight

Interior panels and components(seat backs and overhead compartments) ⇛ weight-saving and aesthetic

Construction industry

Roofing panels⇛ lightweight and corrosion-resistant

Siding panels⇛ lightweight, easy to install, and require minimal maintenance

Building components(gutters, downspouts, and flashing)⇛ formability and weather resistance

Other applications:

Household appliances(Cooking utensils, cookware, and appliance housings)⇛ heat conductivity, formability, and aesthetics.

Medical devices(syringes and prosthetics)⇛ biocompatibility, strength, and lightweight properties.

Telecommunications (antenna housings and enclosures)⇛ conductivity and corrosion resistance