When it comes to sheet metal fabrication the term like tool and die is often used. In general discussion tools are referred to as any general or specific tool used is sheet metal forming; it can be a jig, a fixture or even a metal cutter. As for the dies, it's a piece of metal on which all specific features are present to bend, cut or shape the metal sheet.

Tool Vs. Die

Metal forming dies and tooling has specific importance. Like the general definition of the terms tool & die, in metal stamping is referred to as anything used to stamp the metal sheet. Any jig, fixture, cutter or bender used in the process will be referred to as a tool used in the metal stamping process.

As for a die in metal stamping, a piece of metal given specific shape to cut, bend or impose any specific shape on a metal sheet will be referred to as a die. So in broad terms each die is a tool used in metal stamping but not all tools can be called dies.

Metal stamping tools and dies are more commonly called tooling. Tooling can be referred to as any jig, fixture, die or even to the process & cost of manufacturing. For example when you discuss your project with us, we will use the term die tool and tooling cost to mention the need, the producers, and cost involved in developing tool and die needed for your sheet metal stamping of your product.

Metal Stamping Die Types

Based on what type of metal stamping process they need to perform or how difficult the shape is that they need to process. Following are the types of metal stamping dies from JCLDD sheet metal fabrication manufacturer about deep draw manufacturing.

Simple Dies

As their name refers, a simple die tool is simple in shape and they usually have one or two features. They are used to perform a single sheet metal Stamping process. They can be used for cutting or forming. These days are used in the simplest of procedures where only one single motion can produce a complete part or official. These dies are most cost effective, easy to maintain, and easy to manufacture.

Compound Dies

Compound die stamping or those dies that can fabricate more than one feature at a time. For example a compound die tool can do cutting and punching on a sheet metal at the same time. Both of these procedures of cutting and punching are done on the same stage, not on different stages.

Compound dies are the best solution for those products that have simple but multiple features that can be processed in a single stage over a single step. This takes a lot of time and tooling costs thus, reducing the final product cost.

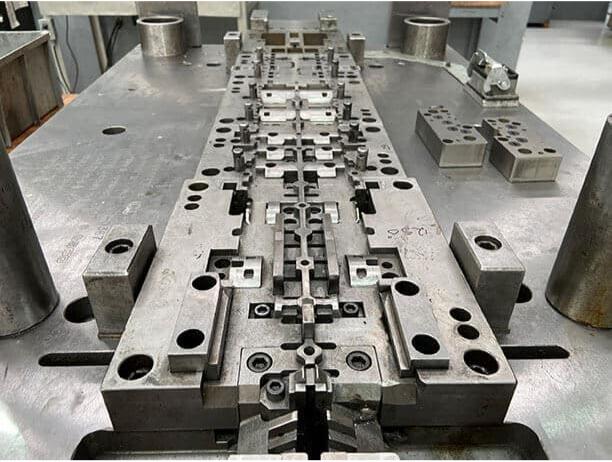

Progressive Dies

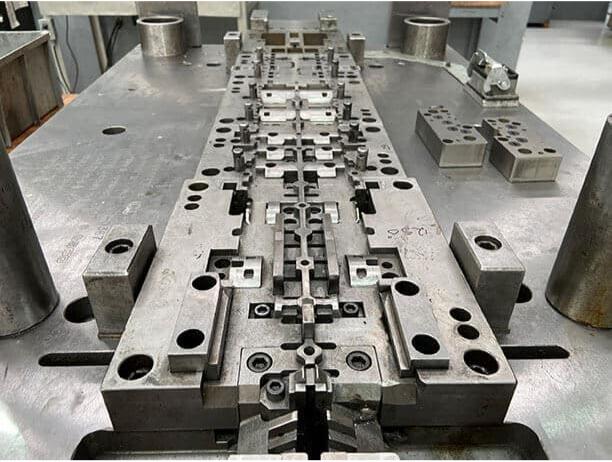

Progressive die operation is the name given to a set of ties that work in a sequence to produce multiple features on a single product. Each die tool in progressive die can either produce a different shape or can work on the shape produced by the previous time either had or any feature required.

Workpiece is moved from one die to another die in a given sequence and each die produces a specific shape on the one piece. These dies are specifically used for those products that have multiple features that cannot be produced in a single stage or the feature is so complex that it needs multiple dies to get the final shape.

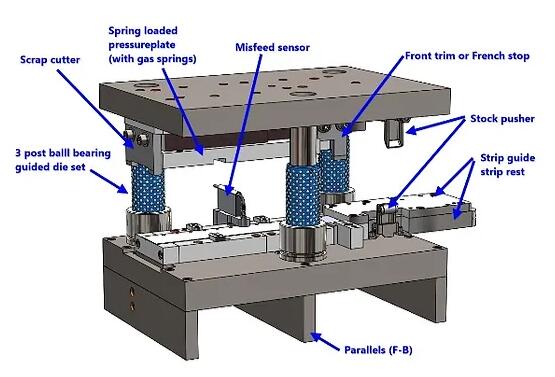

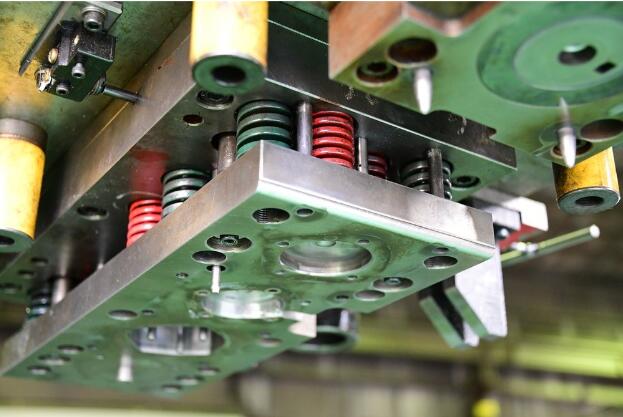

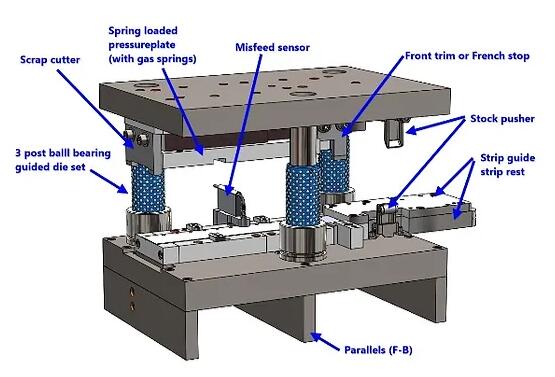

Components of the Die

Type of the day and the shape of the product to be stand. A die tool can have any of the following or all the following components.

The die block

The die block is the main foundation of the entire Stamping process. It is a large piece of metal having the exact shape cavity to form the required shape of the product.

The punch or plunger

Tool used to force the metal sheet into the type lock. It is the plunger that forces the metal sheet to move into the die and take the exact shape of the die cavity.

The Stripper

In sheet metal stumping stripper is the part that is developed to remove the sheet metal part from the plunger once the sheet metal has taken the exact shape of the cavity.

Pilots

Pilots or the small jigs or fixtures that are designed for each and every stumping product. These Pilots are used to guide the sheet to the exact position during the Stamping process. These Pilots make sure that the sheet is placed properly as per the position of the tool and die.

Guide Pins

Guide pins are developed to align the die with the punch movement. These pins make sure that the two and four motion of the punch is always proper with the die cavity.

Materials Used for the Die

Depending upon the product and the process requirement I can be manufactured from different materials. Two of the common materials used in die manufacturing are steel and Aluminum alloy.

Steel Die

Steel die is used in all those applications where a thick sheet metal or material of high strength is being stamped. Steel dies are known for their strength, robustness but take more time and resources during manufacturing. There are tool steels like high speed steel, high-carbon and chromium steel, low-alloy steel, etc.

Aluminum Die

Aluminum die is used in all those aluminium deep drawing where a thin or a soft metal sheet is being used for product stamping. Aluminum dies are known for their lightweight, good strength and excellent surface finish.

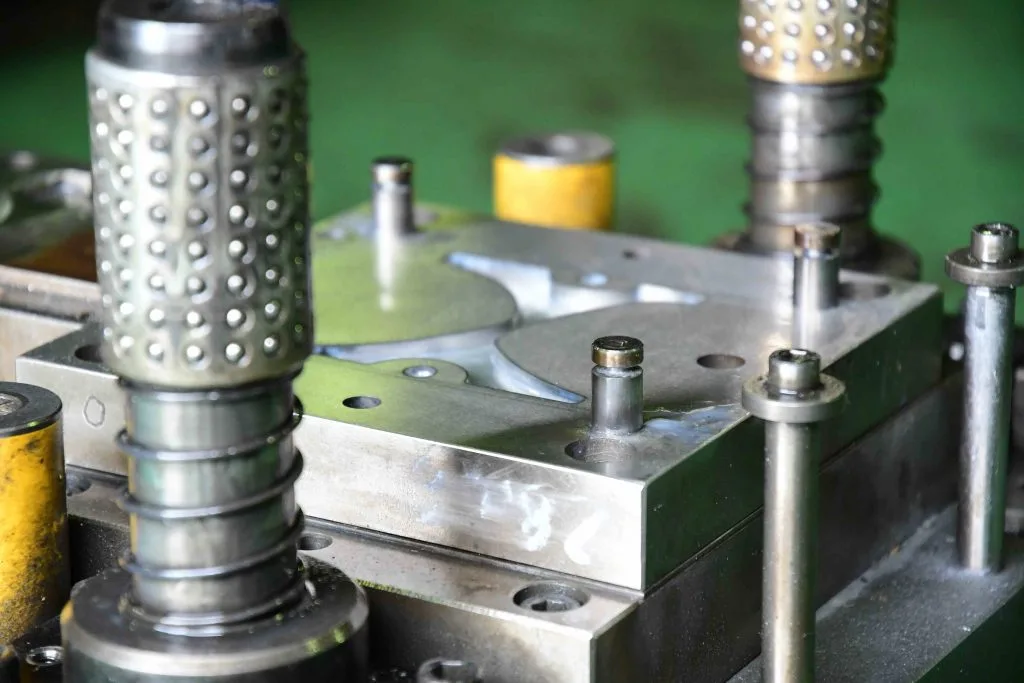

Manufacturing Of Dies

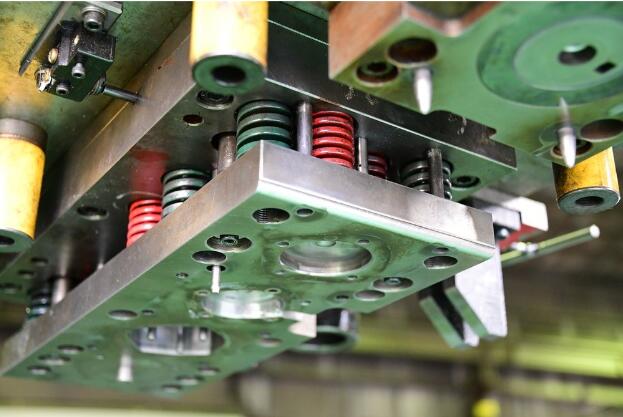

The manufacturing of dies is usually referred to as tooling. The manufacturing process needed to fabricate dies depends on the type, materials and design of the die. A simple die can be manufactured using a simple machining process whereas complex or compound dies might need more one and complex manufacturing processes to complete.

Subtractive manufacturing method of machining is the most used process and CNC machines like CNC machining center and CNC turning center are the two most used machines to manufacture dies. CNC machines are known for their precision and ability to deliver very high quality products.

Before starting the manufacturing process for the dies, a CAD model of the product is developed. From that product CAD model the CAD file of die is generated. A die is nothing more than a piece of metal with all features of the product that are developed using a subtractive/machining process.

The die CAD file is then imported into a CNC machine which works to manufacture die as per the requirement.

Use of Die in Manufacturing Industry

Expertise in tool and die manufacturing has opened the door for cost effective manufacturing of all those products that were previously considered impossible to manufacture at low cost. Two of the most common sheet metal fabrication processes and industrial metal stamping that use tools and dies are sheet metal deep drawing and sheet metal stamping.

In sheet metal deep drawing the tool and die quality defines the final product. As the tool usually a punch forces the sheet into a die of required shape. So design and perfection of tool and die will define the

In sheet metal stamping a metal sheet is cut, bent or shaped to get the required product. So the tool & die are designed as per the need and product shape. The accuracy of the die manufactured defines the final precision and accuracy of the product.

JCL Your reliable partner of stamping tool and die manufacturing

As an enterprise with over 20 years of experience in manufacturing metal stamping dies, JCL can provide you with a comprehensive service system. From design to manufacturing to final production, we are capable of independently completing every stage. Our engineers, on average, have designed nearly a thousand sets of metal processing dies, possessing rich experience in the field. Our die processing workshop is equipped with advanced machinery capable of achieving precision up to ±0.008mm. We have various types of punch presses to meet your production needs, whether it's large-scale production or customized sampling. Please contact us for further information. We are always at your service.