Engineers use metal forming techniques like deep drawn stamping to shape sheet metal into intricate, three-dimensional designs. This sort of cold shaping method makes a section with a profundity more noteworthy than its diameter by dragging or hauling a sheet metal into a press chamber. Hence, A metal framing procedure we call drawn stamping is utilized to shape sheet metal materials into hollow cups or cylindrical pieces. From small cups to gigantic vehicle boards, engineers utilize this versatile strategy to create an extraordinary scope of shapes. The production area and manufacturing sector utilize this innovation broadly to deliver great parts with fantastic consistency and accuracy. All the information you require about deep drawn stamping is provided here:

1. What is Deep Drawn Metal Stamping?

Here is the answer to the question what is deep drawn stamping? "Stamping" refers to a general classification of metal-forming strategies with various modern purposes. The subsequent parts arrive in diverse sizes, from monstrous and complicated pieces we found in the development of vehicles, machines, and airplanes to parts as little as 0.25 inches in diameter.

This strategy, which is some of the time referred to as metal stamping, is called cold framing or cold working, as it is normally completed at room temperature. So, converting flat sheets into three-layered shapes is known as metal drawing, a subset of stamping that considers more prominent innovativeness while making various parts.

For a better understanding of how metal drawing works, its numerous applications, and the advantages it provides, additional research into the process's is recommended. Here are some ideas from JCLDD sheet metal fabrication manufacturer.

2. Steps of Deep Drawn Process

A sequence of deep drawn stamping process is utilized in the deep drawn stamping cycle to change flat metal sheets into perplexing three-layered structures. Being a fascinating and versatile cycle's, engineers use it in many businesses, from making drink jars to trim vehicle body boards or panels. That is why we are coming up next with a profound methodology required for drawn stamping:

Step 1. Preparation:

Sheet metal material selection, Taking into account the requirements of the eventual and perfect outcome, select the right metal materials. Consider attributes like strength, protection from erosion, and formability, and normal materials you use are copper, metal, aluminum, and treated steel.

Start with the blank and sheet metal cutting services, which is a flat sheet of metal. As often as possible, the blank is cut into an exact shape that almost looks like the completed product. The dimension and geometry of the expected part decide the clear's size and shape.

Step 2. Deep Draw Tooling Setup:

The punch and deep drawing die are crucial components that influence the final shape of the component. For them to persevere through the shaping powers, premium apparatus steel is generally utilized in their development.

During the drawing system, lubricants and greases are applied to the blank and die to bring down friction and tearing.

3. Other Forming Operations of Deep Drawn Stamping

Dimpling is a subset that includes particularly deep draw forming. On the outer layer of a metal drawing sheet or part, this method creates little, confined indents or depressions. Engineers use dimpling to add a texture or design plan to the completed item, either for utilitarian or tasteful reasons. Aside from being stylishly satisfying, dimpling is a valuable strategy in an extensive variety of assembling applications since it can work on underlying uprightness by spreading pressure throughout the surface.

Curling is a forming interaction that gives a metal sheet or part a twisted or curled edge. Manufacturers apply this strategy to draw stamping parts to build up their edges, giving them a greater unbending nature and strength. When making enclosures or containers, for example, where the structural integrity of the edge is crucial, curling comes in especially handy. It works on the part's solidarity while adding to the completed item's general sturdiness and safety

A typical accuracy framing method utilized on drawn metal parts to get wanted surface perfection and layered precision is coining. To work on the part's shape, size, or surface properties, the material is packed between two passes in this method. To guarantee consistency and severe resistance in large-scale manufacturing, coining is fundamental. It is broadly utilized in the assembling of essential parts, similar to complex mechanical congregations, electronic parts, and connectors, where exactness and consistency are critical.

Beads, Ribs, & Flangers

During drawn stamping, highlights like beads, ribs, and flanges are made that further develop strength, firmness, or simplicity gathering. Beads are raised lines, flanges are expanded edges, and ribs are structural reinforcement. The stamped part's working and underlying honesty are worked on by these highlights.

Embossing

The enlivening process known as emblazoning makes a raised example or plan on the outer layer of a drawn part. Engineers use this strategy to apply to stamped metal to add marking, branding, or labeling on components.

Extruding

Extruding is the most common way of driving a metal part through a press to stretch or shape it. Extruding can be used in drawn stamping to deliver parts with various cross-sectional profiles, empowering the formation of perplexing shapes and plans.

Ironing

The process of "ironing" reduces the height of a deep-drawn component while maintaining or increasing its wall thickness. This method is used to get precise measurements and make the stamped part better as a whole.

Marking

Stamping is the method involved with giving a deep drawn part recognizing or enlightening highlights. It includes part numbers, chronic numbers, and different markings for assembly, detectability, along quality control.

Holes

Hole punching in deep draw stamping is a regular shaping strategy that makes it conceivable to make holes for the clasp, ventilation, or other useful necessities. Holes can be punched in a variety of sizes and shapes to best serve the intended purpose.

Notches

A fragment of the material is eliminated during the framing system called notching to make a pattern or notch on the edge of a deep drawn part. This methodology is much of the time used to make assembly more straightforward or to account for extra parts in the general item plan.

Threading

Making interior or outside strings on a drawn part is called threading. Engineers consider threading fundamental for pieces that should be bolted or screwed into different parts during assembly.

Trimming

Following the shaping system, sheet metal trim includes eliminating additional material from the edges of a deep drawn part. This guarantees that the finished product will have the right dimensions and characteristics.

Necking

Necking is the method involved with diminishing a drawn part's sectional diameter. Manufacturers consider necking for diameter differences or to make interfacing with different parts during assembly.

4. List of Best Metals for Deep Drawn Stamping

A suitable metal choice is fundamental for stamping to create the expected results regarding formability, strength, and solidness. The combinations that turn out best for drawn stamping typically have a blend of mechanical characteristics like pliability and malleability. In deep-drawn stamping, the following metals are frequently utilized:

Deep Drawn Aluminium:

Aluminum is a typical material for drawn stamping due to its great solidarity to weight proportion, great consumption opposition, and lightweight, exceptionally formable nature. Aluminium deep drawing is suitable for various purposes, for example, electric hardware and vehicle parts.

Deep Drawn Stainless Steel:

Stainless steel is eminent for being enduring and impervious to erosion. Stainless steel deep drawing manufacturing comes in a variety of grades, such as 304 and 316, each with distinctive properties. Stainless steel is frequently used in deep-drawn stamping for medical equipment, car parts, and kitchen appliances.

Deep Drawn Copper:

Because of its high conductivity, copper is much of the time used in drawn stamping for electrical parts. Copper is not as common as steel or aluminum, yet copper deep drawing extraordinary characteristics make it valuable in certain circumstances.

Deep Drawn Brass:

Brass definition includes a copper and zinc combination valued for its appealing appearance and capacity to endure erosion. Brass metal stamping is regularly used in applications requiring solid formability and conductivity, as well as in enlivening drawn parts.

Cold-Steel Alloy

On account of its solidarity and cost-effectiveness, cold rolled steel deep drawing— including low-carbon and high-strength assortments — is broadly used in deep drawn stamping. Because it is a versatile material that manufacturers utilize for various purposes, including modern and auto parts.

Titanium:

Titanium deep drawing is utilized for drawn stamping in circumstances where its momentous solidarity to-weight proportion and consumption opposition are significant while being less well known because of its greater expense. It is often used in clinical and aviation hardware.

Nickel Alloy

Nickel alloys like Inconel and Monel are utilized in deep drawn stamping due to their strength, resistance to corrosion, and capacity to withstand high temperatures. These amalgams are often used in chemical handling and aviation applications.

5. Pros of Deep Drawn Stamping

Deep drew stamping is a versatile metalworking technique that is now common in many industrial metal stamping. Producers find it engaging due to its uncommon precision and productivity in shaping level sheets into perplexing examples. Be that as it may, what makes profound drawn stepping one of a kind? We should analyze its fundamental advantages:

Cost-Effectiveness for Large Volumes:

Drawn stepping is very viable and it has enormous scope for fabricating and manufacturing runs. After the deep draw tooling is arranged, computerization of the cycle can bring about lower work costs and higher creation rates. Delivering enormous amounts of components is subsequently efficient.

Material Utilization:

Since drew stamping genuinely takes advantage of sheet metal drawing, it decreases material waste. By precisely making the expected shape from a solitary sheet, the strategy limits waste and helps set aside cash by utilizing less material.

Consistency and Precision:

Elevated expectations of consistency and accuracy in part creation are ensured by the method. Tight resilience and repeatable precision in the development of unpredictable shapes are made conceivable by the utilization of dies and tooling, which improves the general nature of the fabricated parts.

Materials Diversity:

Numerous materials can be utilized with drawn stamping, including metals like copper, steel, aluminum, and other alloys. Due to their flexibility, makers can choose materials that best meet the novel requirements of the expected use.

Complex Geometries:

Deep drawn stamping makes it conceivable to create intricate and confounded shapes that would be troublesome or costly to deliver utilizing regular manufacturing strategies. This is extremely helpful for making parts with fine specifying or particular plans.

High Production Speeds:

It is a fast and quick strategy, especially for making loads of identical and indistinguishable parts. For large-scale manufacturing, the interaction's quick speed assists with lessening lead times and completion times.

Enhanced Stability in the Structure:

Deep drawing parts again have better structural integrity since there are no joints or creases and the material is circulated consistently. Parts might be more reliable and durable as a result.

Design Flexibility and Personalization:

Drawn stamping is as often as possible connected to mass creation, even though it likewise empowers personalization. Because it can be altered to meet specific design requirements, tooling is excellent for producing both conventional and unique components.

Fittingness for Parts with Thin Walls:

To make thin-walled things without compromising primary uprightness, deep-drawn stamping is a solid match. Here having lightweight parts that fulfill specific strength guidelines is vital.

6.Cons of Deep Drawn Stamping

Before beginning, it is essential to be aware of the limitations and potential drawbacks of deep drawn stamping, despite its numerous advantages. Here is a more intensive view at a couple of disadvantages of utilizing this compelling technique:

1. High Starting Investment:

Specific hardware and tooling are expected to set up the cycle, and these can be expensive. This initial expense may be intimidating when beginning a small-scale production or prototyping project. It can also demand assistance in auxiliary cycles like trimming and managing, machining, or welding relying upon the part's intricacy and the necessary rules. The whole presentation time and cost might increase subsequently.

2. Material Limitations:

Some metals aren't good for deep sketching. Certain deep drawing materials are inclined to tearing or parting during the framing system, like delicate cast iron.

3. Potential for Scrap and Deep Drawing Defects:

The metal deep drawing process can be affected by changes in material thickness, lubrication, and process parameters. As a result, the drawn pieces may have flaws or even tears, raising production costs and costs for scrap. To lessen scrap rates, cautious checking and the monitoring are fundamental.

4. Limited Design Freedom:

Deep drawing allows for the creation of intricate shapes, but there are geometric limitations. Without additional forming steps or specialist procedures, it may be difficult or impossible to create undercuts, steep corners, and certain deep draw ratios.

5. Production Speed:

Deep drawing generally takes longer than other stamping methods. It can require an investment to set up the die and change the interaction boundaries. Moreover, the draw cycle itself might be drowsy, especially for segments with profound shapes or complex subtleties.

6. Strength Considerations:

The material's elasticity might be expanded by the work's solidifying impact during deep drawing, however its malleability and exhaustion life might be diminished. Applications requiring huge bending or effect resistance probably won't be ideal for this.

7. Deep Drawn Stamping Consideration

When considering deep drawn stamping as a production method, several factors must be taken into consideration to ensure a successful and cost-effective outcome. As drawn stamping offers tempting advantages, there are significant things to ponder before beginning. Here are some vital things to consider:

Material Selection:

Select materials for the drawing process that have the perfect proportion of pliability. Common materials include deep drawn aluminum, deep drawn stainless steel, and some carbon steel varieties. Consider the material's formability, strength, and suitability for the expected use.

Part Design:

Make parts that are consistently balanced to accelerate the profound drawing process and stamping mold design. Avoid extremely complicated forms as they may make drawing more difficult. To improve formability and reduce stress concentrations, keep track of the radii, draft angles, and sizes of the fillets.

Material Thickness:

Learn the best thickness of the material you are going to plan for the drawn part. Contemplate finding some kind of harmony between being sufficiently thick to keep away from issues like tearing or kinks and being slim enough for fruitful molding. Because one significant variable impacting the progress of profound drawing is material thickness.

Tooling Design:

You have to invest in the right deep draw tool design. Because having the right instruments is fundamental to obtaining exact and steady outcomes. To increment the apparatus life span and lessen wear and tear, consider components like die material, heat treatment, and deep drawing lubricants.

Tolerance Requirements:

Give the drawn attracted parts' resilience prerequisites in clear terms. Adjust your design in accordance with the limitations of the process when it comes to achieving tight tolerances. Consider whether further machining or auxiliary cycles are expected to fulfill exact prerequisites

Volume Considerations:

Observe the essential creation volume. Both low and huge-volume applications can profit from deep drawn stamping, but in low-volume creation specifically, the financial matters of tooling expenses might affect decisions.

Surface Finish Requirements:

Show the degree of surface finish that the drawn segments should have. Perceive that more advances, such as polishing or coating, could be important to accomplish a smooth surface.

Testing and Prototyping:

To check the design and the careful outlining process, test the model. Almost immediately in the advancement cycle, distinguish any potential issues to overcome costly changes later on.

Supplier Expertise:

Select a reliable drawn stamping supplier with experience and authenticity. Work intimately with the provider to profit from their involvement with material choice, tooling plan, and process improvement.

8.Application of Deep Drawn Stamping

Here are a few normal uses of deep drawn stamping across different industrial metal stamping:

Automotive Components:

The auto business utilizes deep drawn stamping broadly to fabricate different parts. Portions of the fumes framework, fuel tanks, and underlying components are commonplace models. The approach is ideal for meeting the stringent requirements of the automotive industry, where lightweight but durable automotive metal stamping parts are essential for safety and fuel efficiency. It can make muddled and strong designs from sheet metal

Household Appliances:

Deep drawn is regularly utilized in the assembling of domestic device parts, including fridges, stove pits, and clothes washer drums. The technique makes it conceivable to deliver perplexing, very much-shaped metal parts in enormous amounts at a sensible expense, which raises the overall viability and reasonableness of customer machines

Medical Devices and Equipment:

Drawn stamping is also helpful to the medical services area while making various types of clinical gear and devices. This process is as often as possible used to make parts including careful instrument housings, diagnostic equipment enclosures, and implantable gadget lodgings. In the clinical business, medical device component meets severe cleanliness and sterilization guidelines, yet in addition offer accuracy and steadfastness.

Aerospace Applications:

Drawn stamping is utilized in the aviation business to deliver parts for space apparatus and planes. This method is as often as possible used to make parts including aeronautical nooks, primary parts, and motor parts. The ability to construct parts that are both durable and lightweight is especially crucial in aeronautical applications because it enhances overall performance and fuel efficiency.

Electronics and Electrical Components:

Drawn stamping is utilized in the electronic field to make different nooks, associations, and housings. The technique makes it conceivable to make the intricate structures and accurate estimations required for common electronic components. Moreover, drawn metal parts are valuable in applications where obstruction and interference should be decreased because of their electromagnetic protecting characteristics.

Beverage and Food Containers:

Jars and canisters are two instances of the sorts of food and refreshment compartments that are generally made with this process. The technique makes it conceivable to create, areas of strength for consistent, compartments rapidly and really, which assists the packaging area with fulfilling shopper needs for ease and item security.

Power Distribution Components:

Deep drawn stamping is utilized in the electrical and power appropriation industry to make parts including transformer cases, transfer lodgings, and circuit breaker enclosures. The capacity of the interaction to deliver metal parts with careful aspects and shape is fundamental for ensuring the constancy and security of electrical frameworks.

9. Design Tips For Deep Drawn Stamping

An adaptable metalworking strategy that can unequivocally make complex shapes is indeed deep drawn stamping. To stop mistakes and ensure effective part creation, engineers should painstakingly think of this methodology. Coming up next are significant design pointers to remember:

1. Geometry:

Favor smooth transitions and gradual radius changes: Avoid abrupt changes in wall thickness and sharp corners since these could concentrate strain and raise the chance of tearing. Gentle curves and fillets encourage smooth metal flow and reduce wrinkle formation.

Maintain even wall thickness: A wall's rough thickness might cause localized diminishing and even breakage while being drawn. That is why, engineers go for the even conveyance of material across the part.

Minimize depth-to-diameter ratio: More profound segments are bound to come up short and need more power. With regard to complex calculations, engineers need to attempt to keep away from profound profiles and ponder utilizing different phases of drawing.

Symmetrical shapes are ideal: Disparity in the material stream and possible tearing can result from imbalance. Balanced design increment shaping consistency and smooth out die manufacturing.

2. Material:

Choose the right material: The ability to be formed without breaking is known as drawability, and it is different among materials. For profound drawing, utilize pliable materials like deep drawn copper, aluminum, or low-carbon steel.

Consider material thickness: Albeit thicker materials are more strong, drawing them requires more power. Because of the last shape you need and the attributes of the material, pick the right thickness.

Grain direction: Formability might be affected by the sheet metal's grain direction in response to the drawing direction. To amplify the material stream and lower the possibility of tearing, adjust the direction of the grain.

3. Process:

Die clearance: To consider material thickening during drawing, keep up with the proper measure of clearance between the punch and die chamber. The clearance should be hardly more than the expansion in material thickness.

Lubrication is crucial: To bring down friction and upgrade the metal stream, lubricate or grease up the clear and tooling with the proper oil.

Blank holder: To deal with the material's stream and avoid wrinkles, use a clear holder. Changing the clear holder power will guarantee sufficient grinding without deterring the progression of the material.

4. Additional Tips

Utilize simulation deep drawing software

Work with experienced toolmakers

Prototype and iterate

Multiple draws might be necessary:

10. Deep Drawing Vs Other Manufacturing Methods

Deep Drawing Vs Stamping Comparison

Process: Extending a flat blank over a punch into a die cavity produces empty shapes with deep walls, which is the way profound drawing structures parts. Utilizing a press and die, stamping is the most common way of cutting, twisting, or blanking sheet metal to frame various shapes.

Shapes: Empty, cup-like shapes with profound walls and consistent changes are created employing deep drawings. A more prominent scope of shapes, like bent, flat, or flanged pieces, can be delivered by stamping, yet the profundities and geometric intricacy are decreased.

Strength: Since the metal grain adjusts during the drawing system, profound drawn pieces are commonly stronger and more grounded. Contingent upon the material and shaping techniques utilized, stamped parts can have a scope of strength diversity.

Cost: Deep drawing tooling may proficiently make huge volumes of parts, yet it is typically more costly than stamping tooling.

Deep Drawn vs Sheet Metal Stamping

Process: Extending a flat blank over a punch into a die cavity produces empty shapes with deep walls, which is the way deep drawing structures parts. Sheet metal stamping includes a more extensive scope of shaping procedures, including bowing, blanking, penetrating, embossing, and piercing.

Shapes: Empty, cup-like shapes with profound walls and consistent changes are created employing deep drawing. A more noteworthy scope of shapes, like level, bended or curved, flanged, and embossed pieces, can be created utilizing sheet metal sizes.

Strength: Since the metal grain adjusts during the drawing system, profound drawn pieces are commonly stronger and more grounded. The strength of stamped sheet metal parts fluctuates in light of the material and framing strategies utilized.

Cost: Taking into account that deep drawing tooling is more expensive than stamping tooling,

Process: Extending a flat blank over a punch into a die cavity produces empty shapes with deep walls, which is the way deep drawing structures parts. Meanwhile, in casting, melted metal is filled with a shape to frame the expected shape during the projecting system.

Shapes: Empty, cup-like shapes with profound walls and consistent changes are created employing deep drawing. Casting has a more noteworthy scope of shapes, including complex geometries, which can be made through projects, yet there is an opportunity for surface defects and porosity.

Strength: Since the metal grain adjusts during the drawing system, profound drawn pieces are commonly stronger and more grounded. Contingent upon the material and casting method, cast pieces have various densities and qualities.

Cost: Casting is more costly to tools than deep drawing, especially for little pieces. Despite the higher introductory tooling costs, huge parts and complex designs might be more savvy for casting.

Deep Drawn Stamping Vs Machining

Process: Sheet metal is extended to make pieces through deep drawing. Machining is used to accomplish an ideal shape, by eliminating material from a strong block or bar.

Shapes: For empty, cup-like shapes with thick walls, dee[ drawn functions admirably. Even though there is material waste included, machining can make an enormous scope of shapes, including complex shapes and intricate details.

Strength: Grain arrangement gives deep-drawn segments a nonstop strength. Contingent upon the material and machining strategies, machined parts can have many qualities.

Cost: While creating parts in huge amounts with clear geometries, deep drawing might be more affordable. Low-volume assembling or pieces with perplexing elements that can't be made by drawing are more qualified for machining.

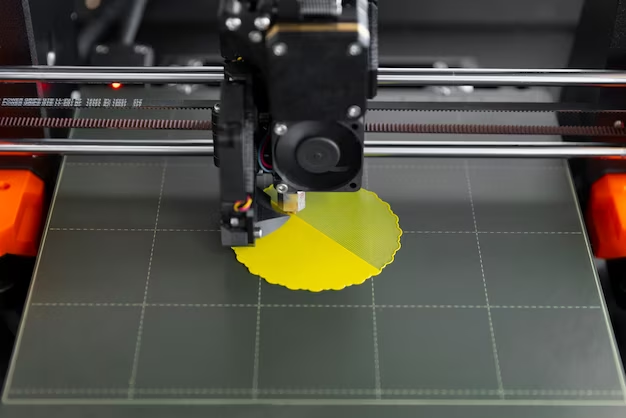

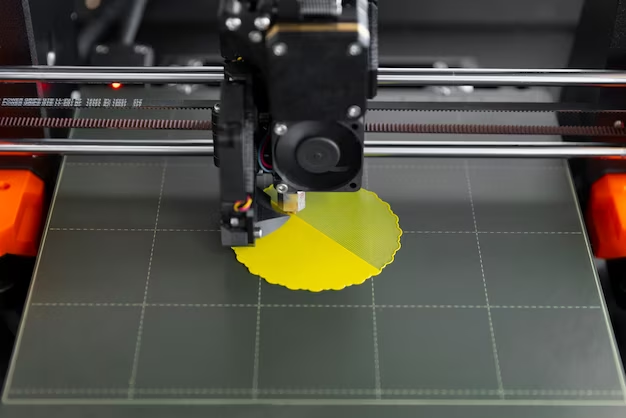

Deep Drawn Stamping Vs 3D Printing

Process: Sheet metal is extended to make pieces through deep drawing. Parts are built layer by layer by 3D printing using combined filament, powder, or resin.

Shapes: For empty, cup-like shapes with thick walls, dee[ drawn functions admirably. Complex calculations with inward elements can be created utilising 3D printing, albeit surface polish and material characteristics are restricted.

Strength: Grain arrangement gives deep-drawn segments a nonstop strength. The strength of 3D printed parts changes in light of the material and printing method utilised.

Cost: While creating parts in huge amounts with clear geometries, deep drawing might be more affordable. Fast prototyping, low-volume assembling, and items with intricate geometries that are hard to make utilising customary strategies are more qualified for 3D printing.

Deep Drawn Stamping Vs Injection Molding

Process: Sheet metal is extended to make pieces through deep drawing. Injection molding creates pieces by pumping molten plastic into a mold cavity.

Shapes: For empty, cup-like shapes with thick walls, dee drawn functions admirably. Complex calculations with inward elements can be created utilizing injection molding, albeit surface polish and material characteristics are restricted.

Strength: Sheet metal — typically steel or aluminum — is utilized in deep drawing. Plastics made of plastic are utilized in injection molding

Cost: While creating parts in huge amounts with clear geometries, deep drawing might be more affordable. Plastic parts with high accuracy and intricacy can be efficiently manufactured with incredible achievement utilizing injection molding.

12. Importance of Deep Drawn Stamping in Manufacturing

Since deep drawn stamping is so flexible, prudent, and proficient, it is a fundamental part of modern manufacturing and assembling. This metal shaping strategy is ideally suited for different businesses, including apparatuses, gadgets, and autos, as it considers the exact mass assembling of perplexing, consistent parts. The ability of deep drawn stamping to create intricate designs from flat sheet metal ensures the best utilization of materials, reduces waste, and improves overall cost-effectiveness. Manufacturing processes are simplified due to their capacity for high-volume production, satisfying industry demands for consistent, affordable, and dependable components.

Conclusion

To sum up, deep drawn stamping is an unimaginably viable procedure that empowers manufacturers to create durable, rich, and useful metal parts rapidly. Far-reaching and continually changing are its applications, going from typical things to best-in-class innovation. Therefore, the next time you admire the flawless finish of a cooking pot or the smooth curve of a car hood, keep in mind how deep drawn stamping has changed the world around you.

FAQs

Is Deep Drawn Stamping Economical for Simple Shapes?

Yes, deep drawn stamping is an economical process for simple shapes.

What are the limitations of deep drawing in terms of material thickness and shape complexity?

There are two major limitations in deep drawing shapes: intricacy and material thickness.

How do different die designs affect the formability and quality of deep drawn parts?

Different deep draw die designs affect the formability in diverse ways, like

Punch and die clearance is used for material flow along with wall thickness and wrinkles.

Blank holder pressure prevents the tear and wrinkles along with the control of material flow.

Radii and transitions are used to reduce stress and smooth curves & improve formability.

What are the latest advancements in deep drawing technology and how are they improving the process?

Latest deep drawing technology advancements like Finite element analysis, Active blank holders, Lightweight die, and Hybrid processes, play significant roles in improving the process by optimizing the performance and design, preventing future mistakes, improving cycle times, etc.

What are the cost factors to consider when choosing deep drawn stamping over other metal forming methods?

There are some factors which you need to keep in mind when you are considering deep drawn like the cost of the tooling, materials cost, production speed and scrap rate, etc.

How can deep drawn stamping be used to reduce waste and optimize material usage?

There are some ways or techniques to reduce waste such as trimming techniques, use of nesting softwares, recycling scrap and choosing the right materials.

What are the quality control standards for deep drawn parts in different industries?

Quality control standards are essential before you launch or introduce the product in the market such as surface finish, dimensional accuracy, and non-destructive testing, etc.