MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding are two popular techniques in the sheet metal welding industry. The MIG vs TIG Welding debate centers around the appropriate use of both welding types.

It’s vital to choose the correct types of welding. Because they directly influence all the aspects of a project. Hence, TIG and MIG welding are used for different purposes. You need to understand the TIG and MIG welding differences, similarities, and their different applications. Only then will you know when and where to utilize which.

Read on to determine if you should go for TIG or MIG welding. Our concise and simple guide will tell you all you need to know. Here are some ideas from JCL sheet metal fabrication manufacturer about deep draw manufacturing.

MIG VS TIG WELDING

Here’s a guiding table that simplifies your understanding of TIG vs MIG welding.

MIG WeldingMIG welding stands for Metal Inert Gas welding. | TIG WeldingTIG welding, or Gas Inert Gas welding |

What is it?

MIG welding uses electricity fuse metal pieces and protects the weld with a shielding gas.

| What is it?TIG welding, or Gas Tungsten Arc Welding (GTAW), welds metal together using non-consumable tungsten electrodes. |

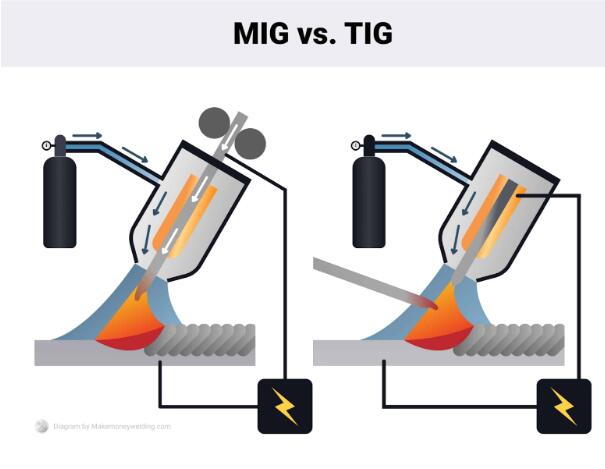

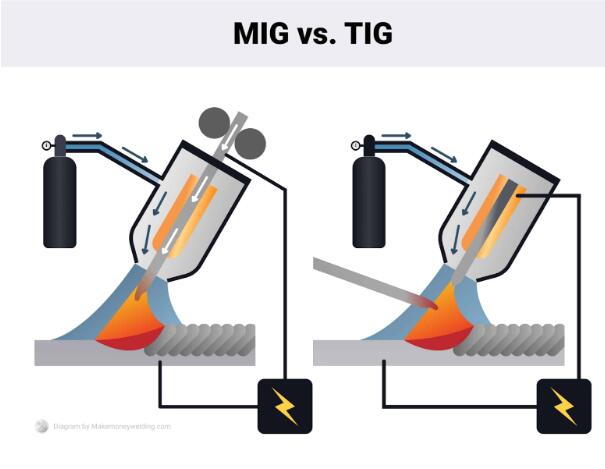

MIG Welding ProcessIn MIG welding, a continuously fed consumable wire electrode is used as a filler material. Welding electrodes are fed through a welding gun. A shielding or MIG welding gas is emitted from the gun to protect the weld from atmospheric contamination. An electric arc forms between the wire electrode and the metal being welded. This melts both the wire and the base metal. The melted materials cool and fuse. They create a strong weld joint.

| TIG Welding ProcessTIG welding uses a non-consumable tungsten electrode to produce the weld. TIG welders sometimes add separate filler metal manually to the weld joint. Inert shielding gas welding, typically argon welding is done to protect the weld area from atmospheric contamination. The TIG welder controls the heat that electric arc welding generates between the tungsten electrode and the workpiece. It melts the base metal and filler material (if used) to create the weld joint. TIG welding produces high-quality, clean welds because of the precise production control.

|

Advantages:Ease of Use: MIG welding is easy to learn and can be quickly mastered by beginners. High Welding Speeds: MIG welding machine has high welding speeds. So, it has large-scale production and reduces project completion times. Versatility: MIG welding machine can weld various metals and alloys, like steel, stainless steel, aluminum, and copper. Cleaner Welds: MIG welding produces less spatter compared to other welding techniques. The cleanliness looks aesthetically pleasing. Automation Potential: MIG welding can be easily automated, improving their productivity and consistency. Cost-Effectiveness: MIG welding is cost-effective because of its efficiency, high welding speeds, and lower MIG welder labor requirements. Reduced Post-Weld Cleanup: Less post-weld cleanup is required from the MIG welder.

| Advantages:High-quality Welds: TIG welding produces precise, clean welds with minimal spatter and distortion. Versatility: TIG welding welds various metals and alloys, like stainless steel, aluminum, titanium, and exotic metals. Control: The welder gets excellent control over the heat input, arc length, and welding parameters. No Flux Required: TIG welding does not require flux. So, the welding process is very simplified. It reduces the need for post-weld cleanup. No Sparks: TIG welding is very safe and clean because it produces no sparks or slag. High-End Applications: TIG welding is in high demand for high-end applications such as aerospace, automotive, and precision engineering. Minimal Distortion: TIG welding minimizes distortion in the welded components.

|

Limitations:MIG welding increases expense with a shielding gas. It isn’t possible to weld in outdoor or windy conditions as the shielding gas blows away. Welders can’t weld thicker materials with MIG welding. The welding process may produce more heat-affected zones. MIG welding fabrication requires proper ventilation.

| Limitations:Skill and Training: TIG welding requires more skill and training. The control over the welding parameters has to be precise. Slower Speed: The TIG welding machine generally has a slower process than MIG welding. That’s why TIG welding falls on productivity and production. Cost: TIG welding tools and products can be more expensive. Limited Positioning: It is more suitable to carry out TIG welding on flat or horizontal welding positions. It is challenging to weld overhead or vertical joints.

|

What you get:Strong Weld Joints: MIG welding produces strong weld joints. They make strong structures and can take the intended loads and stresses. Clean Welds: MIG welding produces clean welds with minimal spatter and distortion. Consistency and Uniformity: MIG welding creates consistent and uniform welds. Minimal Distortion: When welders control welding parameters, they can minimize distortion. Good Penetration and Fusion: MIG welding should achieve good penetration and fusion to gain a strong structure. Appropriate Weld Reinforcement: MIG welding should provide the necessary strength and durability.

| What you get:Precision Weld Joints: TIG welding produces precise and accurate weld joints because they meet tight tolerances and dimensional requirements. Fine Detailing: TIG welding makes detailed and fine weld bead control. Their high precision is sure to create aesthetic components. Minimal Heat Affected Zone (HAZ): TIG welding minimizes the heat-affected zone around the weld joint. This is beneficial because it reduces the risk of distortion and preserves the mechanical properties of the base metal. High Purity Welds: TIG welding has high-purity welds with minimal contamination. Excellent Weld Fusion: TIG welding fuses the base metal and filler material excellently. Low Defect Rate: TIG welding yields low defect rates because of the reliable and consistent weld quality. Suitability for Thin Materials: TIG welding and fabrication of thin materials is done well because the heat input is very controlled. This minimizes burn-through or warping.

|

Factors to Consider When Choosing Between MIG and TIG Welding

There are some specific issues that may arise when choosing between the two welding types. Here’s how you can avoid them and end up choosing the right welding process.

Material Types and Thicknesses

MIG: Shines with thicker materials like steel, aluminum, and stainless steel. Its fast deposition rate makes it ideal for large projects.

TIG: Suitable for precise control. For mig vs tig welding aluminum or stainless steel and aluminum, TIG welding definitely wins.

Here are sheet metal material selection from JCLDD

Desired Weld Quality and Aesthetics

MIG: Delivers strong and functional welds. The spatter and heat input can lead to less polished finishes.

TIG: Produces clean, smooth welds with minimal spatter. It provides superior aesthetics.

Welding Speed and Efficiency Requirements

MIG: Can bear with long welds and high-volume projects thanks to its continuous wire feed and faster travel speeds.

TIG: Has precise control, which needs slower travel speed. This makes bulk production challenging.

Cost Considerations

Skill Level and Experience of the Welder

MIG: Between MIG vs TIG welding for beginners, MIG is definitely more beginner-friendly for easy processing and automated operation.

TIG: Demands more practice and skill to master hand-eye coordination, filler rod manipulation, and arc control.

MIG Welding Applications

MIG welding is primarily utilized for large scale production, high-speed production that can be done with automation. They are most suited for general metalwork and structural fabrication using thicker metals.

Fabrication and Construction

Structural steel: Building bridges, towers, buildings, and frames.

Metal fabrication: Creating gates, fences, furniture, railings, etc.

Shipbuilding: Joining thick steel plates and pipes for hulls, etc.

Industrial construction: Welding heavy equipment, tanks, and pressure vessels.

Automotive and Transportation

Car repair and fabrication: Joining and repairing car bodies, frames, exhaust systems, etc.

Motorcycle repair: Repairing custom parts, frames, and modifications.

Aerospace: Welding aircraft structures, engine components, and other applications (often with specialized MIG techniques).

Manufacturing and Production

High-volume production: Mass producing identical parts due to the speed and efficiency of MIG welding.

Appliance manufacturing: Joining sheet metal components for washing machines and refrigerators, etc.

Agricultural equipment: Manufacturing and repairing farm machinery.

Heavy equipment manufacturing: Joining trucks, excavators, and other heavy components.

Repair and Maintenance

General equipment repair: Fixing welds, cracks, and broken metal parts on equipment.

Plumbing and piping: Joining and repairing pipes and tubing for water, gas, etc.

HVAC systems: Repairing and fabricating heating, ventilation, and air conditioning components.

Art and Sculpture: Creating metal sculptures, artwork, and decorative pieces.

Food and beverage industry

Medical device manufacturing

TIG Welding Applications

You will generally find TIG welding and industrial metal stamping in the aerospace, automotive, and nuclear industries.TIG welding is highly sought after because of its specialized detailed welds and aesthetics, for which it can also be processed on thin materials.

Aerospace

Aircraft structures: Joining wing skin, engine mounts, with materials like aluminum, titanium, and magnesium.

Spacecraft: Manufacturing spacecraft components with high strength, low weight, and resistance to critical environments.

Pipelines Industries

High-pressure pipelines: Joining pipes carrying oil, gas, and other critical fluids.

Chemical processing plants: welding components that can handle corrosive chemicals and high temperatures.

Automotive and Customization

High-performance exhaust systems: Creating leak-free, high-performance exhaust systems for motorcycles and even Formula One cars.

Custom bike frames: Creating aesthetic bike frames, etc.

Classic car restoration: Restoring classic cars to recreate their original beauty and functionality.

Arts & Precision Manufacturing

Medical implants and devices: Creating medical implants and devices.

Jewelry and art: Creating jewelry pieces and metal sculptures with detail.

Electronics and electrical: Welding flimsy components.

Shipbuilding

Furniture and Decoration

Similarities & Differences between MIG and TIG Welding

Although MIG and TIG welding techniques have extensive applications, they have distinct characteristics and variances. Here are essential aspects to evaluate when comparing these two welding methods.

Differences between the Technical Process Parameters of MIG Welding VS. TIG Welding

| MIG Welding | TIG Welding |

Shielding Gases | Basic: argon (Ar) To elevate penetration and liquidity: Helium (He) For all grades: argon/helium mixtures Arc stability, enhance deposit quality, improve fluidity: oxygen (O2) or carbon dioxide (CO2) in small amount

| Basic: argon (Ar) To elevate penetration and liquidity: Helium (He) For all grades: argon/helium mixtures Specialized needs: nitrogen (N2) and/or hydrogen (H2)

|

Welding Torch |

| Non-consumable tungsten electrode. Separate filler rod added manually. May require foot pedal amperage control.

|

Welding Quality Characteristics | Smooth: no craters or dips in the weld bead. Flat bead profile: have no discoloration in a flat bead profile. No defects: No cracks, holes, or excessive splatter. Strong joint: For thinner metals, a clean, strong joint.

| Visually appealing: Smooth, consistent bead with a regular "stack of dimes" pattern. Uniformity: Consistent width, height, and penetration throughout the weld. Cleanliness: No cracks, porosity, or splatter. Color: Bright, uncolored appearance (minimal oxidation). Shape: Consistent weld size matching the joint requirements.

|

Welding Speed: | 15 to 20 inches per minute | 4–6 inches per minute |

Wire Feed Speed: | 240 to 290 ipm for travel speeds from 14 to 19 ipm. | Not applicable |

Wire Diameters: | The thicker the material, the larger the diameter.

E.g. :

0.6mm-0.8mm MIG wire- 5mm thick materials.

1.0mm- 1.2mm MIG wire- 5-10mm thick materials | A larger diameter wire may be better for deep penetration, while a smaller diameter wire may be better for shallow penetration.

Standard sizes: 1.2mm, 1.0mm and 0.8mm |

Similarities:

Both use electricity to create an arc that melts the base metal and filler material.

They require a gas shield (typically argon or helium) to protect the weld from oxidation.

They can both handle a wide range of materials, including steel, aluminum, and stainless steel.

They are both versatile and can be used for various applications.

Technical Parameters:

Differences:

MIG welding is an automatic or semi-automatic process that uses a continuously fed wire as the filler material. TIG welding is a manual process that requires the welder to feed the filler metal separately.

MIG welding is typically faster and more efficient for high-volume production, while TIG welding is slower but provides better control and precision for detailed welding.

MIG welding produces more spatter than TIG welding, resulting in a less polished finish.

The equipment and consumables for MIG welding are generally more affordable compared to TIG welding.

MIG welding is more beginner-friendly and easier to learn, while TIG welding requires more skill and practice.

MIG & TIG Welding Choice of Metal for Applications

The choice of metal for MIG or TIG welding depends on the specific application and desired properties. Here are some common metals used in MIG and TIG welding, along with their applications:

Steel: MIG and TIG welding can be used to weld steel, commonly found in construction and manufacturing industries.

Aluminum manufacturing: TIG welding is often preferred for welding aluminum due to its higher precision and control, making it suitable for industries such as aerospace and automotive.

Stainless steel deep drawing manufacturing: TIG welding is the preferred method for welding stainless steel, which is commonly used in food processing, medical devices, and other industries that require corrosion resistance.

Titanium deep drawing: Due to its high strength-to-weight ratio, TIG welding is commonly used to weld titanium in aerospace and medical device applications.

Magnesium: TIG welding is preferred for welding magnesium, which finds applications in aircraft and automotive industries due to its lightweight properties.

FAQ’s

Which welding method is better for beginners?

MIG welding is generally considered more beginner-friendly due to its simplicity and ease of use. However, with proper training and practice, anyone can become proficient in TIG welding as well.

Is one method of welding more efficient than the other?

It depends on the specific application. MIG welding is typically faster and more efficient for high-volume production, while TIG welding provides better precision and control for detailed welding.

Do I need different equipment for MIG and TIG welding?

Yes, MIG and TIG welding require different equipment, including specific welding machines, torches, electrodes, and shielding gas. However, some machines can perform both MIG and TIG welding with proper set-up and accessories.