Steel is an alloy of iron where carbon and other elements are added into iron to convert iron into steel. As iron is one of the most abundant metals found in earth crust, so there is a lot of work done to make it more useful to humans.

There are about 3500 different compositions of steel already developed and mass produced around the globe. These 3500 different compositions are further grouped into different classes or types. These mainly include carbon steel, alloy steel, stainless steel, structural steel, medical grade, and tools steel.

Here we will focus only on carbon steel and explain its definition, different compositions, uses, advantages and limitations.

What is carbon steel

As the name say’s, carbon steel is what is made after adding carbon in iron. There is a fixed percentage of carbon from 0.05 to 2.1 percent that is added into the iron to make carbon steel.

If carbon percentage falls below 0.05 or goes above 2.1 % then it can be steel but not carbon steel. There are a lot of other alloying elements like chromium, cobalt, titanium, etc that are added in iron to make carbon steel of desired properties but they are added in such minute quantities there is no fixed limit for them.

What does carbon do in carbon steel

As a general rule of thumb, adding more carbon to the iron makes it more stronger, harder, heat treatable and less ductile. This increase in strength and hardness is upto a specific point and after that it starts to decrease dramatically.

How carbon steel grading system works

There are so many different compositions of carbon steel available in the market that they have to be divided into different grades.

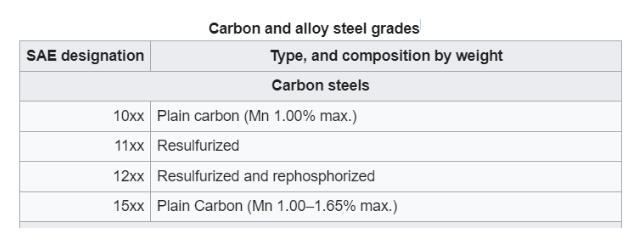

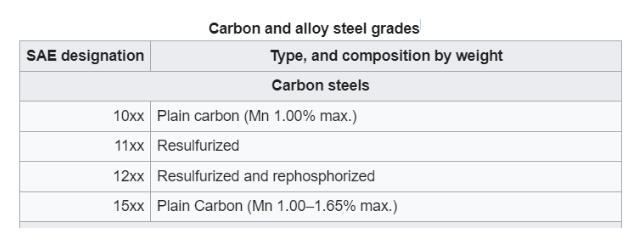

International standard bodies like American Society of Testing Materials ASTM, American Iron and Steel Institute AISI, and Society of Automotive Engineering SAE make a grading setup. Grading setup is mostly based on material properties and industry wise applications.

The ASTM grading system

The American Society of Testing Materials ASTM is mainly responsible for developing grades for all types of materials. They have developed over 12000 different codes that work to give materials their grade.

ASTM code assigns a letter to each material and then assigns a number to define its exact properties range. An example of this is the letter A is assigned to iron based materials like steel. So a code A36 will define a material whose base is iron and 36 refers to exact mechanical properties.

AISI and SAE grading system

Similarly the American Iron and Steel Institute AISI and Society of Automotive Engineering SAE also have their own code to assign grades to materials. Their coding and grading mechanism is designed to grade material for their specific application. The SAE 1XXX series refers to carbon steel.

AISI and SAE grading for carbon steel works by assigning numbers to materials like AISI1010. Now AISI represents the standard issuing body and 1010 helps to read about materials. First two digits tell about the material type and the second two digits tell about carbon percentage.

In AISI1010 the first digit 1 shows material is plain carbon steel, second digit “0” shows it has no alloying element so it's not an alloy steel. Third and fourth digits combine shows the carbon percentage in material that is 0.10% in this example referring materials as low carbon steel.

What are different types of carbon steel

Just based on the quantity of the carbon in iron, carbon steel can be divided into four main types. Each type has further grading of materials based on the properties and industry wise use.

What is low carbon steel

As the name said, low carbon steel is one that has the lowest percentage of carbon among all the types of carbon steel. The other name for this type is mild steel and it's the most used carbon steel in the world.

Low carbon steel contains anything from 0.05 to 0.32 % of carbon in iron by weight. The exact percentage of carbon will define the mechanical, physical, and chemical properties of low carbon steel and thus the exact grade of material.

Commonly used grades of low carbon steel

Following are some of the most common grades of low carbon steel with their applications.

ASTM A36

The ASTM code A36 refers to steel grade A36 which is a low carbon steel specifically designed for structural work like building and bridges. Any steel composition that claims to be ASTM A36 needs to satisfy a specific range of material properties and carbon content specified by ASTM.

ASTM A513

ASTM A513 with grade 1010 is also a low carbon steel but is specifically designed for applications like spare parts of automotives and other industrial scale machinery.

SAE J403

SAE J403 with grade 1006 shows that 1 here represents steel with next 0 showing that there is no other alloying element added into steel. The next two digits 06 show that steel is low carbon steel as it has 0.06% carbon by weight.

Properties of low carbon steel

Low carbon steel is the most used material and its wide application is due to the fact that it is the most cost effective materials available in the market. Additionally this carbon steel has excellent manufacturability.

It can be bent, cut, sheared, machined, welded and can be processed through any surface finish process required. Low carbon steel processes excellent material properties and range of some of most required properties are as follows.

Property | Value |

Density (g/cm³) | 7.85 |

Young's Modulus (GPa) | 200 |

Tensile Strength (MPa) | 250 - 400 |

Yield Strength (MPa) | 210 |

Hardness (Brinell, HB) | 60 - 150 |

Elastic Limit (MPa) | 200 |

Poisson's Ratio | 0.29 |

Thermal Conductivity (W/m·K) | 50 |

Specific Heat Capacity (J/kg·K) | 450 |

Thermal Expansion (10^-6/°C) | 12 |

What is Medium carbon steel

Medium carbon steel is what came right after the low carbon steel range. It has a carbon content of 0.33% to 0.60% by weight. Medium carbon steel has more carbon than mild steel thus it has higher strength and hardness with good ductility and formability.

Better strength and hardness of medium carbon steel came at a cost and it cost more than mild steel. Like the mild steel, this carbon steel also has very good weldability and can be processed through different manufacturing processes like machining, bending, cutting, and forming. With carbon, there are other elements attached to this type of steel to make it more useful.

Common grades of medium carbon steel

Following are some commonly used grades of medium carbon steel from different standards.

SAE J403

SAE J403 with grade 1045 shows that 1 here represents carbon steel with next 0 showing that there is no other alloying element added into steel. The next two digits 45 show that steel is medium carbon steel as it has 0.45% carbon by weight.

This specific grade of carbon steel is developed and used for manufacturing of gears, shafts and machine parts.

SAE J403

SAE J403 with grade 1050 shows that 1 here represents carbon steel with next 0 showing that there is no other alloying element added into steel. The next two digits 50 show that steel is medium carbon steel as it has 0.50% carbon by weight. This specific grade of carbon steel is developed and used for manufacturing of brake discs, brackets, clips, and clutches.

Properties of medium carbon steel

Like other types of carbon steel, the medium carbon steel has a high tendency to react with moisture and rust. Due to their limited resistance against rust and corrosion, this steel cannot be used in moist atmosphere and in marine application.

To use this steel in open atmospheric application, special coating of other materials or paints are needed. Some of the basic mechanical and materials properties of medium carbon steel are as follows.

Property | Value |

Density (g/cm³) | 7.85 |

Young's Modulus (GPa) | 200 |

Tensile Strength (MPa) | 600 - 900 |

Yield Strength (MPa) | 450 |

Hardness (Brinell, HB) | 160 - 220 |

Elastic Limit (MPa) | 280 |

Poisson's Ratio | 0.29 |

Thermal Conductivity (W/m·K) | 50 |

Specific Heat Capacity (J/kg·K) | 450 |

Thermal Expansion (10^-6/°C) | 11 |

These values are approximate and they can vary depending on the specific composition of material and any heat treatment process done to the medium carbon steel.

What is High carbon steel

High carbon steel is where iron has a carbon percentage between 0.6 to 2.0 by weight. This is the highest percentage of carbon in carbon steel and thus this type has the highest strength, hardness and toughness.

At the same time this type has lowest ductility, highest cost, and is most difficult to process to manufacture products from all types of carbon steel.

Due to its high strength and hardness this material is mainly used in all those applications that need extra strength to perform. All grades of this high carbon steel made by ASTM are made by keeping in view its high strength and applications.

Commonly used grade of high carbon steel

Some of the most common high carbon steel grades are explained.

ASTM A29

The ASTM A29 standard code issued by ASTM covers a wide range of materials. It contains AISI / SAE 1060, AISI / SAE 1065, AISI / SAE 1070, and AISI / SAE 1080. All these grades show carbon steel, with no other alloying element added into steel.

The code shows the carbon percentage from 0.60% to 0.80% by weight that indicates its a high carbon steel.

All these materials are used in manufacturing of stress application products including heavy duty springs, gears, axles, cutting tools, industrial scale knives & blades, and automotive suspension components.

Properties of high carbon steel

Due to high carbon content, it is very difficult to weld high carbon steel as compared to mild steel. It is also very difficult to bend, form and punch high carbon steel and its brittle and can crank during such a process.

High carbon steel is mostly processed at elevated temperatures to make it less prone to fracture during stress products during manufacturing processes like bending and forming.

Like all other types of high carbon steel there are other materials like molybdenum, chromium, vanadium, cobalt etc that are added in iron to get desired properties from steel.

Some of the common materials properties of high carbon steel are as follow

Property | Value |

Density (g/cm³) | 7.85 |

Young's Modulus (GPa) | 200 |

Tensile Strength (MPa) | 700 - 1000 |

Yield Strength (MPa) | 550 |

Hardness (Brinell, HB) | 200 - 400 |

Elastic Limit (MPa) | 400 |

Poisson's Ratio | 0.29 |

Thermal Conductivity (W/m·K) | 50 |

Specific Heat Capacity (J/kg·K) | 450 |

Thermal Expansion (10^-6/°C) | 11 |

As always, these values are approximate and can vary based on the specific composition and heat treatment of the high carbon steel.

How carbon steel is different from alloy steel

There is only one main difference between carbon steel and alloy steel and that is the carbon steel has carbon as the major and alloying element in iron whereas in alloy steel other elements like chromium or molybdenum are also added in iron as major alloying element.

This difference in composition is responsible for all the other differences that might be there between two steel types. The composition defines the material properties like strength, toughness, hardness, ductility, and other properties like that.

Last Words

The carbon steel being the most widely used metal as compared to all other types of steel and other metal needs a complex grading system. Standard organizations like ASTM, AISI and SAE develop and issue codes for material grading.

The grading system makes the material application process easy by making sure that material who claims to be of a specific grade has the required specific properties. The grading system also makes it very easy for material handlers to pinpoint any material their client wants.