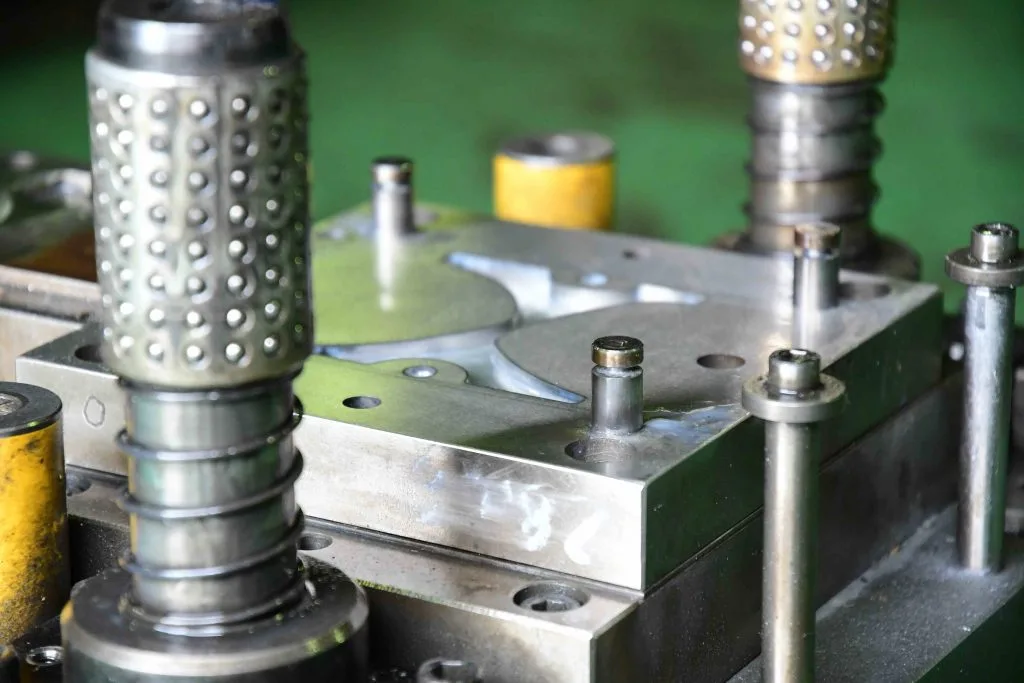

What is deep drawing of metal?

Deep drawing of metal is similar to metal stamping. When the drawing depth is greater than the diameter, metal cold stamping is referred to as deep drawing. Because the deformation capacity of metal is limited, secondary or reverse drawing is required for the production of deeper products.

Applications of deep drawing metal include packaging, furniture, kitchenware, and others.

Characteristics of deep drawing brass

Copper-zinc alloy composition

Deep drawing brass is composed of copper and zinc in a certain proportion, combining the ductility of copper and the hardness of zinc, exhibiting excellent comprehensive mechanical properties. This alloy design enables good formability and strength in the deep drawing process.

Low coefficient of friction

Compared to many other metal materials, deep drawing brass has a relatively low surface friction coefficient. This characteristic makes it more durable and less prone to wear in applications requiring sliding or friction parts.

Non-ferromagnetic

Deep drawing brass is non-ferromagnetic, meaning it is not attracted to magnetic fields. This property is especially important in applications requiring no magnetic interference or electromagnetic shielding, such as electronic device enclosures.

Easy recyclability

As a high-value metal alloy, deep drawing brass is easily recyclable. The material recycling process consumes relatively low energy, is environmentally friendly, and aligns with the concept of a circular economy.

Natural antibacterial properties

Deep drawing brass has good antibacterial properties, effectively inhibiting the growth of bacteria and microorganisms on its surface. This makes it an ideal material for medical devices, food processing equipment, and sanitary facilities.

Corrosion resistance

Deep drawing brass shows strong resistance to various corrosive environments, maintaining material stability even under humid, salty, or acidic conditions. This corrosion resistance extends its lifespan and reduces maintenance costs.

With the above characteristics, deep drawing brass is widely used in precision manufacturing, electronics industries, decorative industries, medical devices, and other fields. It is a high-quality material that combines performance and environmental protection.

Advantages of deep drawn brass stampings

Durable

Deep drawn brass stampings are made from high-quality brass, which offers excellent durability. The brass material itself has superior corrosion resistance and mechanical strength, effectively resisting wear and environmental erosion, making it suitable for long-term use. This durability reduces maintenance and replacement frequency, saving users subsequent costs.

Precision

Through the deep drawing process and advanced mechanical manufacturing technology, deep drawn brass stampings can achieve high dimensional accuracy and complex designs. This precision is difficult to attain with other manufacturing methods (such as manual processing or casting), making deep drawn brass stampings particularly suitable for high-detail and high-consistency requirements.

Cost-effective

Brass is an affordable metal, combining performance with price advantages. It has good machinability and relatively low raw material costs, making the production costs of deep drawn brass stampings competitive. Whether for small batch customization or large-scale production, businesses can balance cost and quality through this process.

Wide applications

Brass has excellent ductility and plasticity, suitable for making various complex shapes and structures. Therefore, deep drawn brass stampings are widely used in many fields, including:

Automotive industry: Used for precision parts such as connectors and seals.

Household items: Such as lamps and decorative pieces.

Electronics industry: Contacts and conductive components.

Construction industry: Decorative panels, fittings, etc.

In summary, deep drawn brass stampings, with their durability, precision manufacturing, cost-effectiveness, and versatility, provide an efficient and reliable solution for the manufacturing industry. They are suitable for various scales of production needs and can meet the application scenarios of multiple industries.