Do you plan to switch to laser cutting, or are you new to the metal industry? Laser-cutting machines are a revolutionary technology in the metal-cutting industries due to their fast and efficient cutting. In fact, the usage of laser cutters is increasing day by day- from welding metals and non-metals to micro-drilling diamonds.

We have curated this article to let you know everything about the process.

What is a Laser Cutting Machine?

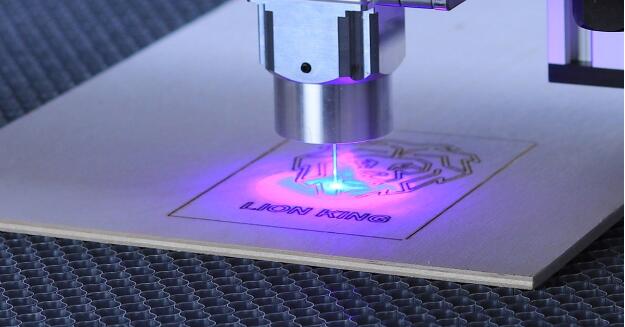

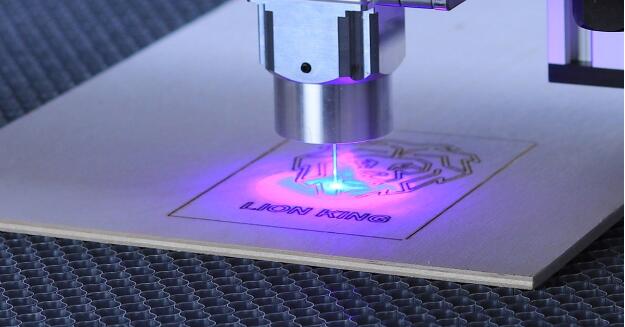

A laser-cutting machine works by vaporising, burning or melting the material to achieve a certain design through a beam. The machine is controlled using CNC and uses CAD and/ or CAM to make the designs.

The laser itself is a beam of light that is achieved by stimulating different lasing materials. The beam is then focused onto the material through the use of mirrors and lenses, and CNC is then used to direct the beam to cut according to the client’s demands.

The Different Types of Laser-Cutting Machines

The answer to this is not simple since it hugely depends on how specific or vague you are getting about it, but in general, there are four main types:

CO2 lasers

Fibre lasers

Nd: YAG/ Nd: YVO lasers

Direct Diode lasers

CO2 Lasers | Fibre Lasers | Nd:YAG/ Nd: YVO lasers | Direct Diode Lasers |

These laser-cutters work by turning CO2 into a beam of light. The CO2 gas molecules are ionised through a power supply, which then emits photons. Apart from CO2, nitrogen, hydrogen and helium are also used for the beam. These are also the most used laser cutters due to their versatility and affordability compared to other cutters. They are great for both metals and nonmetals but are not as good as fibre lasers when it comes to cutting thick sheets of metal.

| Fibre lasers use optical fibres as the source of their beams. These are then amplified by the use of elements such as ytterbium or erbium. Fibre lasers are more versatile than CO2 lasers. They are better suited for metals of all types and are more energy efficient than CO2 lasers. Furthermore, they provide more precision, productivity and accuracy. | Just like fibre lasers, Nd: YAG/ Nd: YVO lasers are known as solid-state lasers. What sets them apart is their use of crystals (neodymium), which is unlike the rest. Though they are grouped together, Nd: YAG (neodymium-doped yttrium aluminium garnet) and (neodymium-doped yttrium vanadate) work slightly differently. Nd: YVO has a much higher pump absorption and gain than Nd: YAG. Also, due to the slightly different crystal structures, Nd: YAG operates in the near-infrared range, emitting 1.064 μm of wavelength. Meanwhile, Nd: YVO can emit both 1.064 μm and 1.34 μm. They are best for cutting metals like stainless steel, brass, copper, carbon steel and aluminium. However, they are not very efficient with thin sheets and can only cut a handful of non-metals. | Direct diode lasers directly use the laser light that comes from utilising a single semiconductor junction, usually made from gallium arsenide. They are simpler in construction as compared to other lasers, such as CO2 lasers that need a lot of mirrors and lenses, and direct diodes only use half a mirror. Unlike crystal lasers, diodes can operate in a variety of wavelengths in the near-infrared range. They offer excellent energy efficiency due to their simplistic construction, leading to lower operating costs. They are also well-suited for cutting a variety of metals and non-metals, along with low maintenance costs. However, diodes have a low beam quality, making them not as efficient as other laser cutters. |

Advantages of the Laser Cutting Process

Can be Used on Different Materials

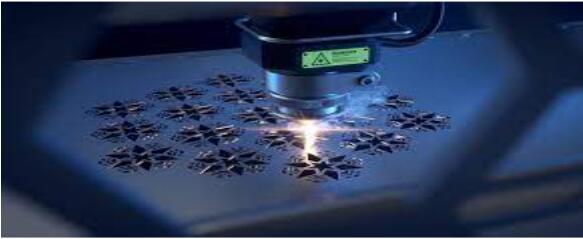

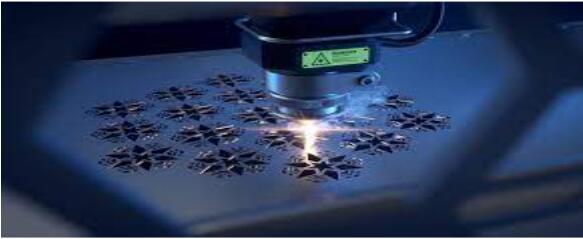

Laser-cutting machines allow for flexibility. Various materials, including metals and non-metals, can be worked upon depending on the laser machine being used. Of course, some laser machines are better at cutting certain materials than others, but overall, they can cut a wide variety of metals.

Can be Used in Various Industries

Laser-cutting machines offer high precision, fast delivery and flexibility, which has enabled them to be used in various industries such as the automotive industry, advertising industry and kitchenware industry, among many others.

Less Human Labour/ Automation

Thanks to CNC, CAD, and CAM, human labour has been reduced greatly in these industries. Most of the time, you only need an operator and no other labour. This greatly reduces labour costs, which reduces the operating costs.

Contactless Cutting

Laser cutters use beams, meaning there is no contact between the machine and the material in question. The advantage of this is that no mechanical friction will ruin the material or the tools being used. This is especially good if the material is something as delicate as fabric.

Precision and Versatility

The narrow laser beam, along with the use of CAM and CAD, ensures that the final product is as accurate and precise as possible. Furthermore, laser machines allow for more intricate designs than human hands could achieve.

The existence of multi-axes provides further versatility since more cuts other than horizontal and vertical can be used and of different thicknesses and hardness.

High Speed and Productivity

Laser-cutting machines cut materials at high speed, which is not possible with manual labour. This leads to higher productivity with faster turnovers and lower long-run average costs.

Disadvantages of the Laser Cutting Process

Material Thickness

No matter the type of laser-cutting machine you use, there will always be a limitation on the material thickness. The limitation is 12 mm, above which the material cannot be cut. Even then, a material of this thickness requires a large machine to cut through it.

Toxic Gasses

Not every material and metal can be cut under the laser. This is because the burning/ vaporization can lead to the release of toxic gasses and fumes which are not suited for humans. Some of these materials include laminated fiberglass, polycarbonate (PC), PTFE, etc.

High Capital Cost

There is a high capital cost when it comes to investing in laser-cutting machines since these machines are not cheap at all.

For example, the most widely used laser cutter is a CO2 laser cutter, which can range from around $2000 to $1000000. However, a $2000 is an entry-level laser cutter and cannot be expected to give high-end results.

If you want a more versatile laser cutter, e.g. a fiber laser cutting machine, then the cheapest one will cost you around $30000, which is a huge sum.

Conclusion

The laser-cutting process comes with both advantages and disadvantages., but the advantages surely outweigh the latter. Investing in a laser-cutting machine will definitely make your business more competitive and efficient.

That also requires investing in the right kind of laser-cutting machine- one that suits your business’s products and goals.

FAQs

What are the advantages of CO2 laser cutting?

CO2 laser cutting machines are cheaper than other kinds of laser cutting machines. Moreover, they are efficient and provide far greater accuracy and precision than traditional methods.

What are the disadvantages of CO2 lasers?

CO2 lasers are notorious for their high maintenance costs. CO2 lasers require mirrors and lenses, also known as consumable parts, that need to be replaced frequently since they depreciate quickly. Furthermore, CO2 is not as energy efficient or versatile as fibre lasers.