In today's rapidly evolving manufacturing industry, custom sheet metal stamping is playing a crucial role in shaping the future of production processes. As businesses seek to stay ahead of the competition and meet the increasing demands of customers, it's important to stay informed about the latest trends in custom sheet metal stamping. In this blog, we'll discuss the top trends shaping the future of custom sheet metal stamping and how they are impacting the industry.

Automation and Robotics

One of the most significant trends in custom sheet metal stamping is the increasing use of automation and robotics in the production process. Advanced technologies have made it possible to automate repetitive tasks and increase efficiency in sheet metal stamping. By implementing robotic solutions, manufacturers can improve precision, reduce cycle times, and increase the overall output of their operations. Automation not only enhances productivity but also ensures consistent quality in custom sheet metal stamping.

Sustainability and Eco-Friendly Practices

With a growing emphasis on sustainability and environmental responsibility, manufacturers are turning to eco-friendly practices in custom sheet metal stamping. By using sustainable materials and adopting energy-efficient processes, businesses can reduce their carbon footprint and minimize waste. Additionally, the recycling and reuse of scrap metal in sheet metal stamping are becoming more common practices, leading to a more sustainable and environmentally friendly production process.

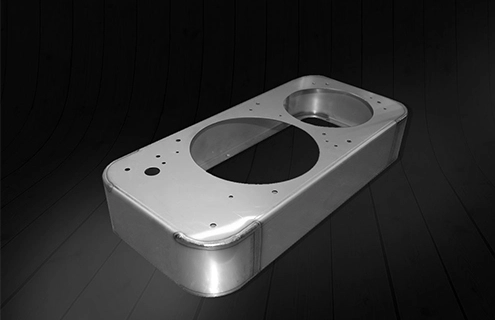

Advanced Materials and Technologies

The use of advanced materials and technologies is another trend driving the future of custom sheet metal stamping. From high-strength alloys to lightweight materials, manufacturers are constantly exploring new options to enhance the performance and durability of their products. With the development of new materials and technologies, sheet metal stamping can now accommodate complex designs and intricate shapes, opening up new possibilities for customization and innovation in manufacturing.

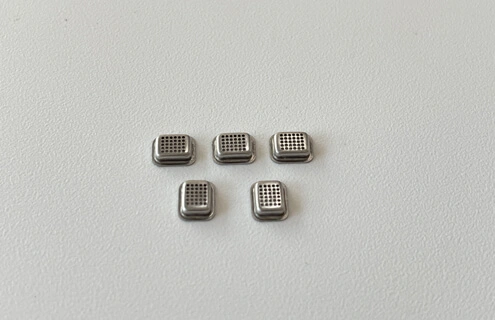

Customization and Personalization

In a market where customization is becoming increasingly important, custom sheet metal stamping plays a key role in meeting the individual needs of customers. From unique designs to personalized finishes, manufacturers and sheet metal stamping parts suppliers are working to offer a wide range of customization options in sheet metal stamping. By leveraging advanced techniques such as laser cutting and CNC machining, businesses can create bespoke products that stand out in a competitive marketplace. Customization is not only a trend but a necessity in today's consumer-driven market.

In conclusion, custom sheet metal stamping is witnessing significant advancements and innovations that are shaping the future of manufacturing. From automation and robotics to sustainability and customization, these trends are driving the industry towards a more efficient, sustainable, and customer-centric approach. As businesses continue to adapt to changing market demands, custom sheet metal stamping will remain a critical component of modern production processes. By staying informed about the latest trends and technologies in sheet metal stamping, manufacturers can position themselves for success in a rapidly evolving industry.