Stainless steel is one the most used type of steel and its mainly due to its excellent corrosion resistance properties.

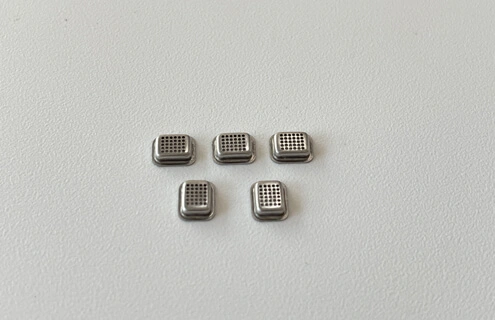

Stainless steel is used in your home cooking utilities, kitchen electrical appliances, and in industrial applications where corrosion resistance is needed like outer covers for electrical equipment, automotive parts and other physical products.

To satisfy such a large domain of application, there are several grades of stainless steel developed. Two of the most common grades of stainless steel are stainless steel 304 and stainless steel 316.

What does grades of stainless steel mean?

The grades of stainless steel are governed by different standards developed by different countries around the Globe. Some of the most common standards are ASTM, AISI, SAE, and JIS.

Their standards are developed by different countries or organizations to meet certain requirements. ASTM (American Society of Testing Material) is developed and regulated by the United States of America whereas JIS (Japanese Industrial Standard) is developed to meet Japanese industrial standards.

Stainless steel deep drawing manufacturing, the most widely used Steel type, is used extensively in both America and Japan for several industrial applications. To make it convenient both Americans and Japanese have developed abbreviations for stainless steel like SS has been developed by American and SUS has been developed by Japanese.

Does SS and SUS are same

In common comparison the SS and SUS are same. These both referred to stainless steel just for different countries and in different standards. This means in common comparison SS 304 and SUS 304 are the same materials.

The only difference is that the SS 304 satisfies the AISI standards and SUS 304 is designed to satisfy the Japanese standard. So other than common applications is there any difference between SS vs SUS.

Differences Between SS vs SUS

SS vs SUS, both SS and SUS represent stainless steel in two different standards applied into different parts of the world. In order to fully understand how SS vs SUS are different from each other we need to compare material directly from both standards.

Let's take an example of stainless steel 304. For AISI the grade code for these materials will be SS 304 and for JIS the grade code will be SUS 304. As the same material is developed and utilized as per two different standards so there are some differences between SS 304 vs SUS 304.

Apparently the SUS 304 has higher corrosion as compared to SS 304 at room temperature. The SUS 304 can maintain its properties better at lower and higher temperature conditions and it has a bit better mechanical properties as compared to SUS 304.

The SUS 304 also has better manufacturability as it is easier to weld and can be processed through cold rolled process.

This difference between SS vs SUS is due to the difference in chemical composition of the same stainless steel material developed to satisfy different standards. The chemical composition of SS is a bit different from SUS.

The carbon content is higher is SUS 304 as compared to SS 304. The SUS 304 has 0.08 percent carbon by weight while SS 304 has 0.07 percent carbon by weight. This higher concentration of carbon makes SUS 304 more stronger and harder than SS 304.

The SUS 304 has higher concentration of silicon and chromium as compared to SS 304. The SUS 304 has greater than 1 percent of silicon as compared to 0.75 percent present in SS 304.

Similarly the SUS 304 has about 20 percent chromium by weight which is 0.5 percent more than that is present in SS 304. This higher concentration of silicon and chromium increase the corrosion resistance of SUS 304 as compared to SS 304.

Conclusion

To fully understand the differences between SS vs SUS, we have compared the SS 304 vs SUS 304. This result shows that SUS being developed on JIS standards has a bit higher strength, higher corrosion resistance, and higher manufacturability as compared to SS 304. This increase in strength and corrosion resistance is mainly due to a slightly higher percentage of carbon and chromium in SUS 304 stainless steel.