Steel and titanium are both the most common metals available in modern industry, they are very often being used in stamping operations due to the appearance, strength, formability and other unique properties. Although steel has been created into a broad family of alloying varieties that make it the real “king of metal”, titanium also is a full spectrum of materials with exceptional properties. Let's dive into the interesting maze of these two materials and sort out what is different and how you can use them well.

Composition

Steel, as you know, is a compound of iron, carbon, chromium, nickel, manganese, and many more elements, which a refinery adds when they need to adjust its properties. The content of top 5 elements are

Iron (Fe): 98-99%, it is the base metal of steel

Carbon (C): 0.08-2%, some main types of steel are defined by their carbon content

Manganese (Mn): 0.25-1.5%, usually used to improve strength and hardness

Silicon (Si): 0.15-2%, Often being added as a deoxidizing agent

Chromium (Cr): 0.5-18%, you can easily find it in stainless steel because its corrosion resistance and hardness.

You may hear that steel has different phases under heat treatment. That is a vital definition when you are looking into microstructure of metals. Steel phases determine all the properties of itself. The most important three phases in steel are

Ferrite is a less carbon contented crystal structure, meaning it has less hardening effects, which can be found in ductile mild steel.

Austenite has much more carbon than ferrite, It is the primary phase in carbon steels above the eutectoid temperature and in austenitic stainless steels at all temperatures.

Martensite is formed by rapid cooling austenite, the carbon crystals dispersed in iron as needles, interfering with the plastic deformation of iron atoms. It is very hard and brittle.

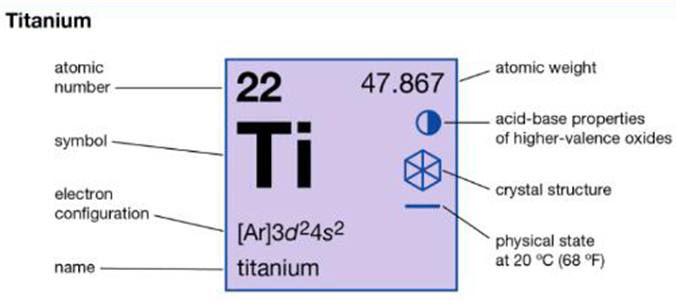

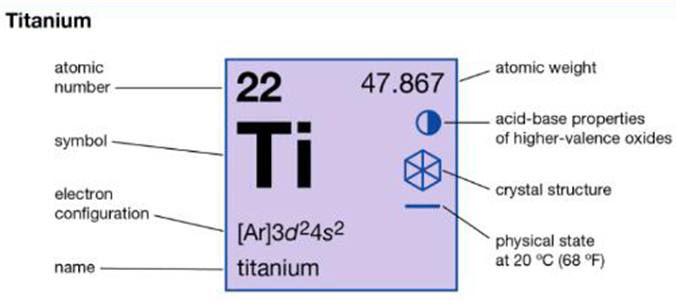

Titanium is the 22th element in the periodic table. It exists in the natural earth in pure and compound forms. Because it has two electrons in the 3d subshell and two in the 4s subshell, it tends to be in the state of +2, +3, and +4, which exhibits as in TiO, Ti2O3 and TiO2 respectively. TiO2 is the most stable compound that is widely used in coating ingredients.

Titanium has two phases in room and high temperature. Alpha phase exhibits at room temperature and up to about 882 degrees Celsius. Alpha stabilizers include aluminum, oxygen, and nitrogen. Beta phase is stable above 882 degrees Celsius for pure titanium. Beta stabilizers include molybdenum, vanadium, and niobium. When titanium is in the beta phase, it can be more easily worked and shaped. Alpha and beta are also easy to mix to present a good formability.

Property

Now you know the composition is totally different between steel and titanium, no matter in the types of atoms (elements) or cluster of atoms (microstructure). You must be curious to see how the titanium deep drawing and stainless steel deep drawing manufacturing behave in a perceivable world. Next you're going to see comparison of various properties between steel and titanium.

Density & Weight

Titanium is well known for this weight-strength ratio, its density is only slightly more than half of steel alloys. That means titanium is only about half of the weight at the identical volume. This is a great advantage while you are looking for strong metal materials but don't want a heavy weight, especially when you work in the automotive or aerospace industry.

Strength vs Strength

Tensile Strength: Pure titanium’s tensile strength ranges from 240 to 370 MPa and common steel’s range of 400 to 580 MPa. But some titanium alloys can be stronger than quality steel after a special conditioning process. Overally, steel is still stronger than titanium in this very aspect.

Yield Strength: in terms of this specification, it has the same trend as tensile strength. But you should know that yield strength represents the threshold for irreversible deformation, whereas tensile strength is the threshold for failure/breakage.

Young’s Modulus: Titanium has a modulus of elasticity of about 110 GPa, which is around half of steels. You can see steel is a very rigid material.

Toughness: Titanium has high toughness, it is remarkable especially its toughness seems irrelative to temperatures. That means it can keep the same good toughness in cold places like polar regions and deep space . Steel has good toughness too, you can tune by composition and heat treatment.

Hardness

Titanium's hardness is generally lower than steel. It is a softer but sticky material compared to steel, especially when you are machining or cutting it. But it only refer to steel, titanium is still a very hard material compared to other lightweight metals.

Corrosion Resistance

A layer of oxidation easily occurs on the surface of titanium due to its atomic configuration. So it has excellent corrosion resistance naturally. In other words, we can use this oxidized layer to form color coatings via anodization.

Stainless stainless is one type of steels that have excellent corrosion resistance due to chromium content. Other steels need coatings to prevent rust or corrosion.

Cost

Titanium is much more expensive than most types of steels. Because of

Titanium is less abundant than iron ores

The extraction process for producing titanium metal is more complex and requires more energy compared to that of steel, because titanium has a higher melting point than steel.

Machining titanium is tougher than doing the same with steel. It can be hard on tools, wearing them out faster, and you need special, expensive tools to do the job right. This can make things made with titanium cost more.

Despite the high cost of titanium, you still need its superior properties in many high-tech and critical fields.

Pros and Cons

We have addressed a series of features of the two materials. You can easily conclude their pros and cons.

Titanium’s advantages are super strong but also really light, corrosion resistable, super temperature tolerancing and last but not least biocompatible. However, it costs quite a bit more than other metals like steel, difficult to machine or casting and a relatively poor rigidity.

Steel is really affordable, especially compared to titanium. It's a super common material that is easy to refine, process and recycle. It is a first option of strength and hardness if you are not sensitive to weight. On the contrary, it doesn't have a good weight-strength ratio, easy to rust or corrode, you alway need additional cost of coating it.

Conclusion

Here are some ideas from JCLDD sheet metal fabrication manufacturer about deep draw manufacturing, you can make a decision when choosing these two metals. If you need a strong, light-weight part in a harsh environment, or design to make a medical implant that is able to coexist with human tissues, titanium is your choice. If your priority is hard and strong at a limited budget, steel is always an answer.