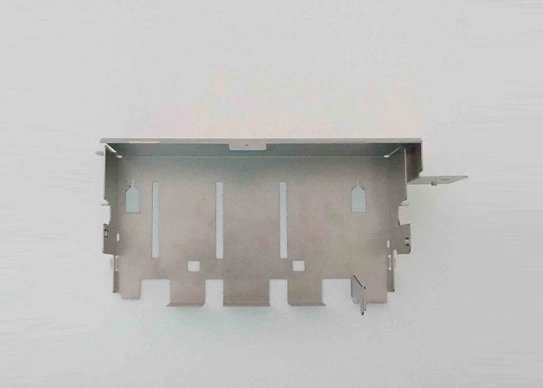

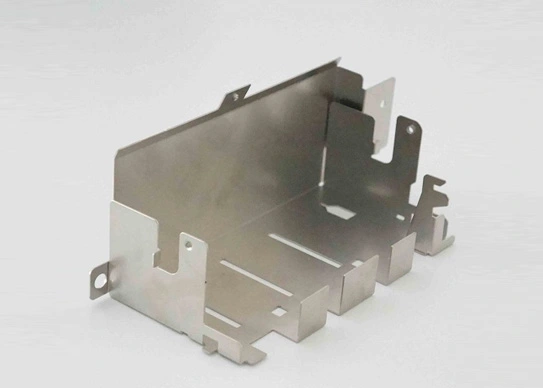

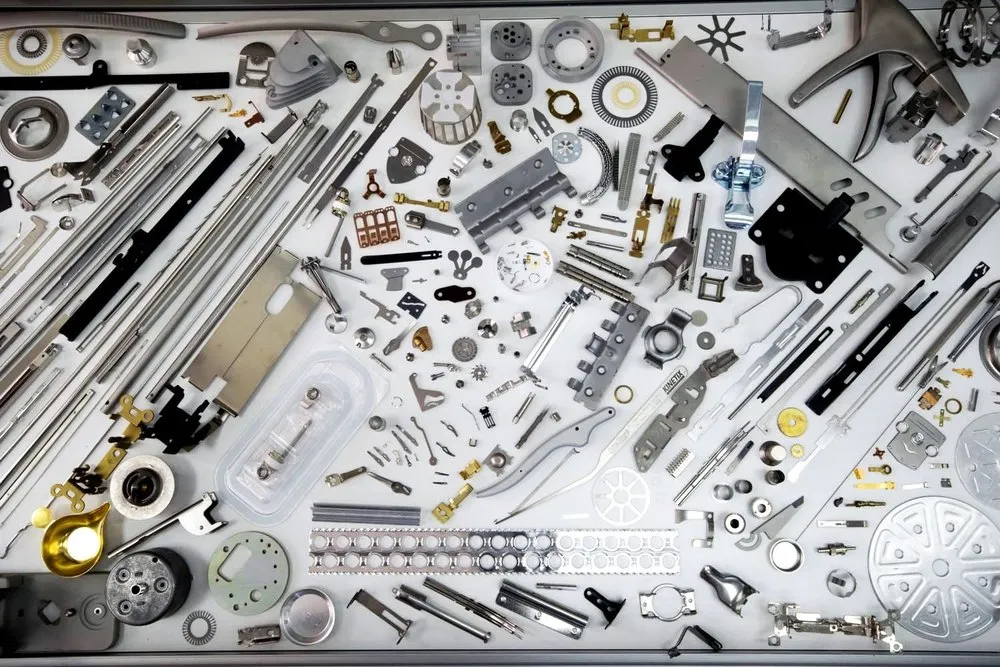

Complex Designs

Challenge: Customers may not understand which design will fit which material.

JCL Solution: Our expert engineering team and advanced tooling capabilities explains and simplifies the requirements and suitability of designs.

Material Compatibility

Challenge: Choosing the suitable material for specific applications can be challenging.

JCL Solution: JCL offers material expertise and guides customers in selecting the optimal material based on application needs.

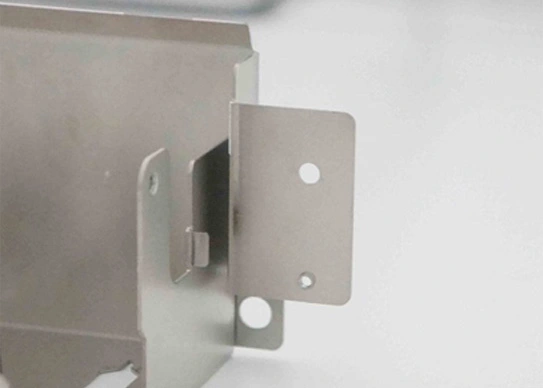

Tight Tolerances

Challenge: Meeting tight tolerances can be difficult and lead to concerns about precision.

JCL Solution: We ensure required tolerances with manufacturing processes and quality checks.

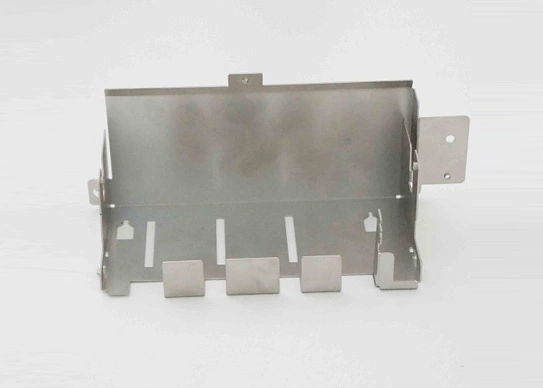

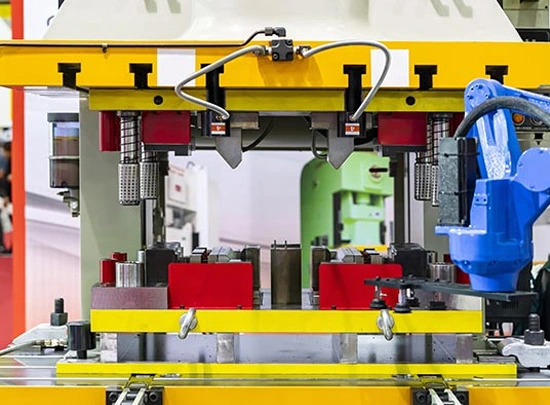

Mass Production Demands:

Challenge: Customers can be met with challenging costs when scaling up production for large quantities.

JCL Solution: JCL efficiently produces high volumes of metal stamping housings.

Cost Management:

Challenge: It’s often hard to balance cost-effectiveness with desired features and customization.

JCL Solution: We help customers achieve the right balance between cost and quality with cost-effective manufacturing processes.

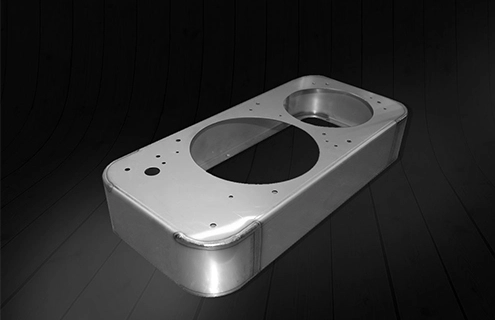

Adaptability to Industry Changes:

Challenge: Design requirements can drastically change when Industries experience changes or advancements.

JCL Solution: JCL stays tuned with industry trends and adapts to changing requirements.