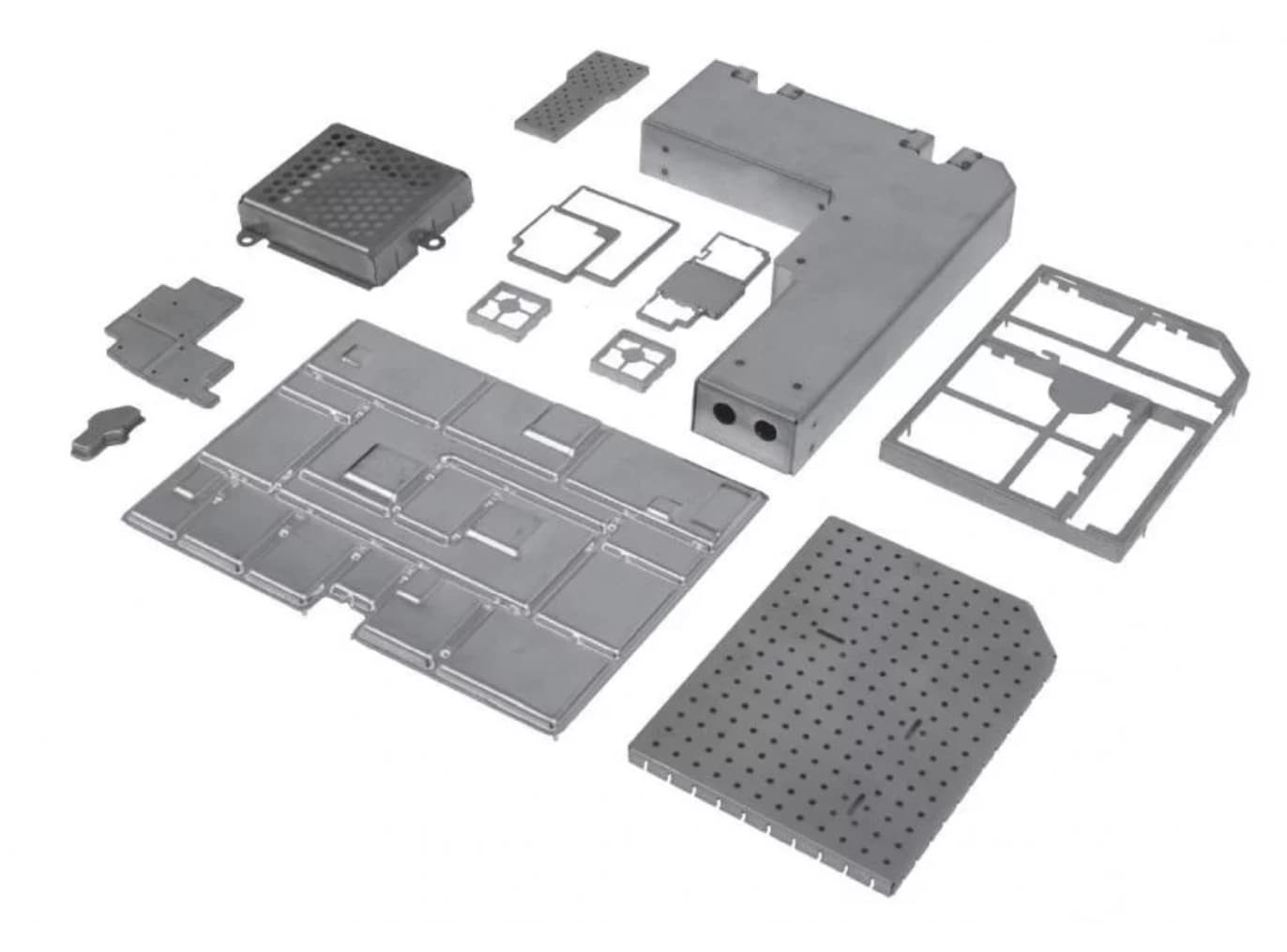

All electrical and electronics circuits are not designed to dissipate heat, they need external assistance to remove heat they produce during operation. Metal heat sinks provide electronic devices a dedicated and extended surface area that help them dissipate heat effectively.

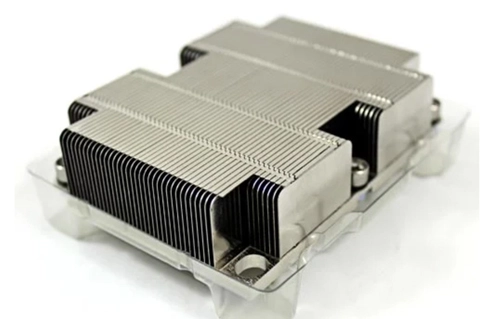

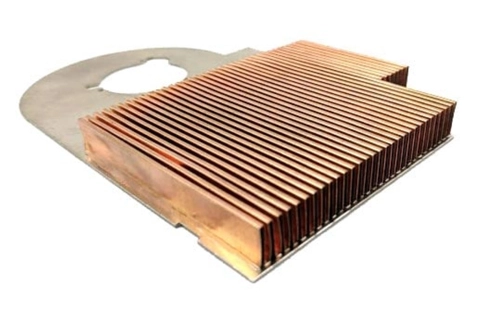

A heat sink consists of a base and fins. Base is attached to the heat source and fins are used to dissipate heat into the environment. In most heat sinks, the base and fins are of the same material and are fabricated from a single piece of material. Base is flat in shape and fins are made thin, perpendicular to the base and can be of any shape.

JCL is fully capable of fabricating and delivering a heat sink of any material but most clients ask for Aluminum heat sink and copper heat sink.

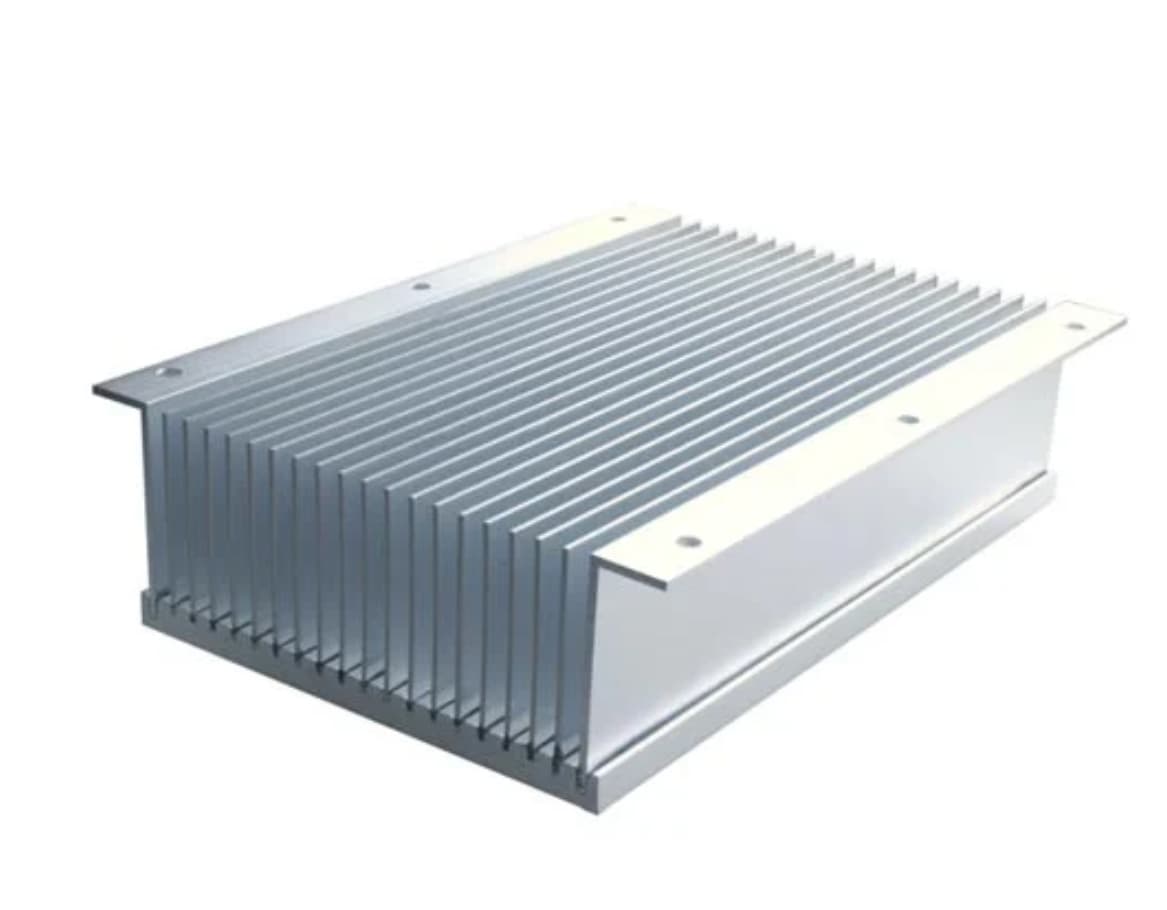

Aluminum Heat Sink

Aluminum heat sink by aluminium deep drawing has the ability to dissipate heat through conduction at the rate of 235 watts per kelvin per meter. Aluminum heat sinks are very lightweight, have high corrosion resistance and are very cost effective.

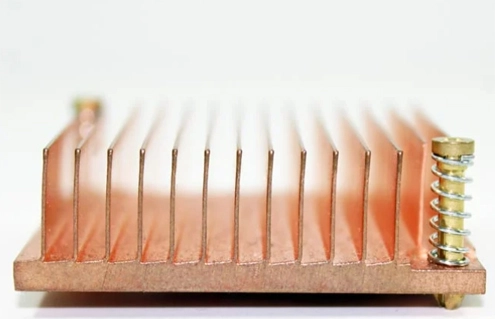

Copper Heat Sink

Copper heat sink by copper deep drawing has the ability to dissipate heat through conduction at the rate of 400 watts per kelvin per meter. Copper heat sinks are high end heat sinks, have high corrosion resistance and are used in critical devices.