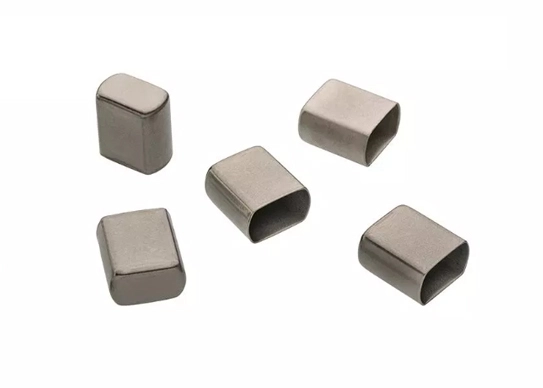

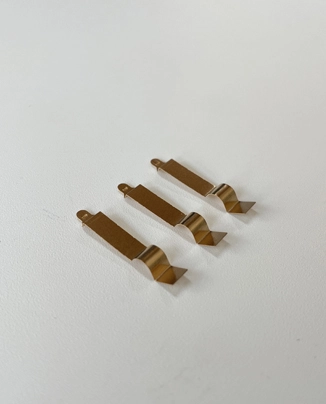

Titanium drawing parts make the best of material innovation with precision engineering. Engineering and deep drawing titanium bring out its properties. This transformation requires flat titanium sheets to be shaped into intricate three-dimensional forms. Their anti-corrosive, lightweight, and heat resistance properties are ideal for aerospace, medical, and industrial applications.

Properties of Titanium Drawing Parts

high reactivity

high strength

springback tendencies.

High Strength-to-Weight Ratio

Corrosion Resistance

Biocompatibility

Durability

Longevity

Excellent Heat Resistance

Low Thermal Conductivity

Non-magnetic

Aesthetic Finish

Chemical Inertness

Formability for Complex Shapes

BENEFITS OF TITANIUM STAMPED PARTS

Durable and long-lasting

These titanium deep drawing components are long-lasting and need minimal maintenance due to their corrosion resistance. This quality gives them high strength.

Versatile

Titanium deep drawing components in titanium allow for the creation of complex shapes and elements for diverse applications due to their high formability, non-magnetism, and non-erosion.

Improved Fuel Efficiency

These titanium deep drawing components have improved fuel efficiency with their lightweight design and high strength-to-weight ratio.

Powerful

Due to their excellent heat resistance, titanium deep-drawing compounds are stronger than copper types.

Aesthetic

Due to its smooth and silken finish, applications with these titanium deep drawing components have an aesthetically pleasing surface.

Features of Titanium Deep Drawing Part

Compliance with Standards

Our titanium sheet metal forming components always adhere to relevant industry standards and specifications.

Traceability

We have a traceable system to track the titanium material's origin, processing, and testing. We record the process to ensure accountability and quality control.

High Chemical Purity

At JCL titanium sheet metal forming supplier, we undergo various measures to ensure high purity levels to keep the material from weakening and compromising its corrosion resistance.

Precise Manufacturing

We give your titanium deep-drawing components dimensional accuracy, smooth finishes, and minimal springback. And you get the most desirable looking, wrinkle-free, fit, and functional component.

Biocompatible

JCL titanium sheet metal forming supplier gives you biocompatible titanium grade for medical applications. So you don’t have to worry about the risk of rejection or adverse tissue reactions.