Transfer Die Stamping Vs Progressive Die Stamping

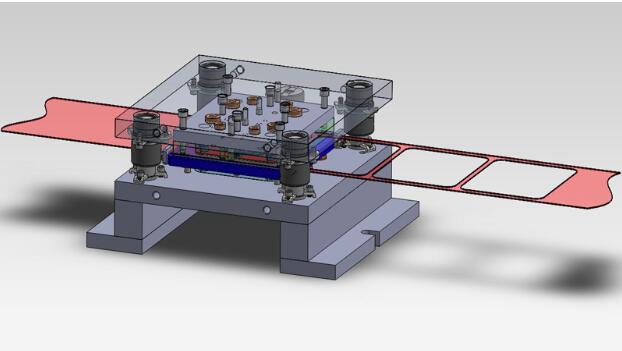

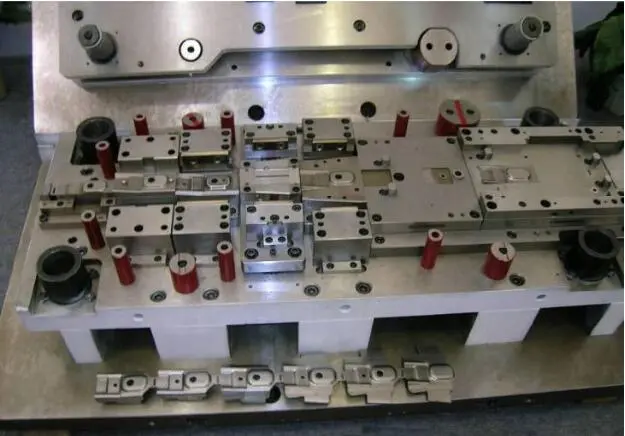

Transfer Die stamping: Although the procedure has a higher starting expense, transfer die stamping gives more noteworthy accuracy and control for complicated things with tight resilience and intricate points of interest.

Stamping with a Progressive Die: Progressive die stamping turns out best for making multifaceted pieces however, progressive die drawing could be less viable while simplifying shapes in enormous amounts.

When You Should Avoid Compound Die Stamping

Review that albeit compound stamping is a powerful method, there is certainly not a one-size-fits-all response. In some circumstances, it probably won't be the most ideal choice:

In Complex geometries:

Compound tooling is not a good choice if you need complicated and tough shapes of your parts. Instead, transfer stamping is an accurate & exact choice if your items require convoluted highlights, tight tolerance, or complex twists.

In Low-Volume Manufacturing:

The starting tooling speculation for compound stamping may not be savvy if you simply need a little cluster of things. As it is not good for short-volume production.

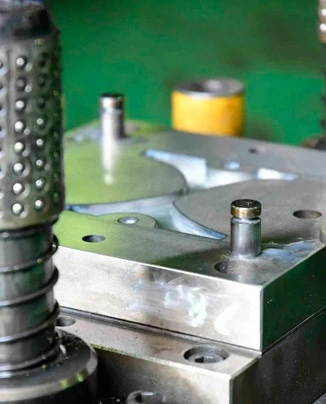

JCL takes on alternative stamping services too for your small and large production orders, focusing on high accuracy and high-volume fabricating utilizing best-in-class move stamping innovation, even though it gives a full scope of metal stamping services. This is how JCL is remarkable:

Unmatched Precision:

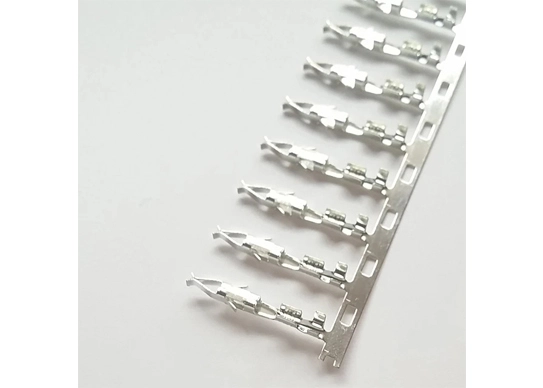

Progressive, transfer, and compound die stamping, which is JCL's area of capability, is known for creating complex, well-honed exactness. Compound die stamping, on the other hand, is geared toward quickly producing simpler shapes. JCL involves synchronized passes in a multi-stage cycle to guarantee reliable and wonderful results, particularly for mind-boggling intricate parts with tight tolerance.