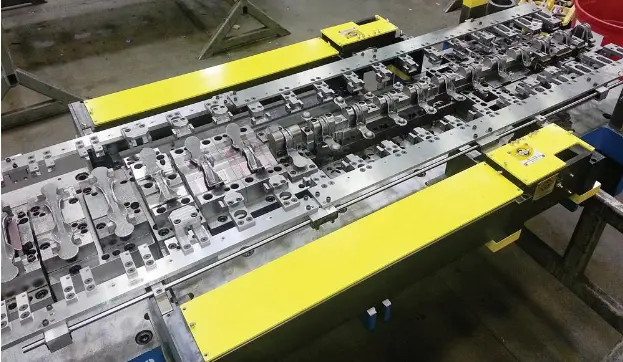

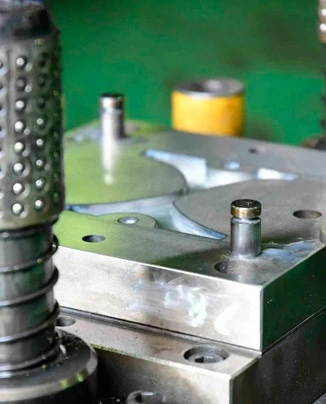

We offer Transfer Die Stamping solutions that meet or exceed your most stringent requirements by combining cutting-edge technology with our extensive experience. The range of possibilities of JCL from complex electrical parts to uncompromising car parts are endless. JCL's transfer dies stamping services are suitable for:

Automotive:

JCL is molding the fate of mobility with primary structural components, engine brackets, sections, and chassis, as well as electrical contacts and strong housing.

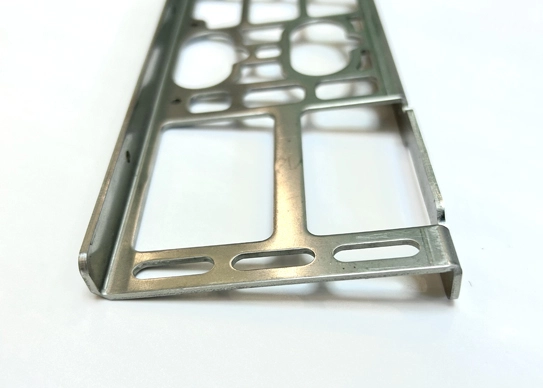

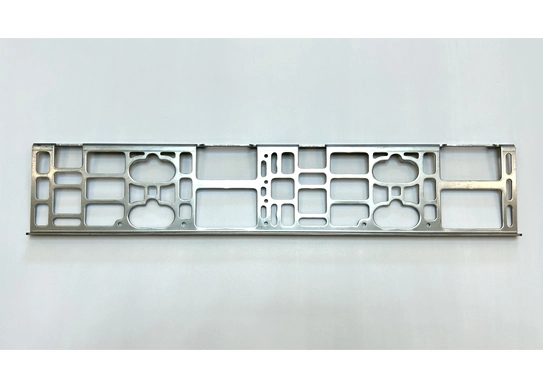

Electronics:

JCL's meticulous metalworking makes complicated connectors, nooks, crafted enclosures, brackets, and heat sinks.

Surgical Devices:

Careful devices, prostheses, and, surprisingly, sensitive diagnostic equipment benefit from JCL's enduring obligation to precision.

Aerospace:

JCL's skill empowers lightweight, high-strength parts like slats, elevators, flaps, rudders, stabilizers and spoilers along with precision in flight control systems for airplanes and satellites to fly.

Consumer Goods:

From exquisite machine parts and eye-getting flatware to enriching decorations that offer a bit of extravagance, JCL makes everyday items that work in our lives.