1. Simple Stamping Dies:

Single-station dies are used for various actions like cutting, molding, shaping, piercing, notching, bending, trimming, etc. Manufacturers apply these dies to manufacture and design simple and less sophisticated parts.

Manufacturers consider simple stamping dies perfect for those applications where simple part geometry is required and the created volume doesn't need the use of more complex tooling. They are practical and effective for making crucial parts in a large number of various industries including electronic, automotive, and household items. A few simple stamping dies are explained here.

Blanking Dies

Piercing Dies

Notching Dies

Trimming Dies

Lencing Dies

Coining Dies

Bending Dies

Shaving Dies

Cutting Dies

Embossing Dies

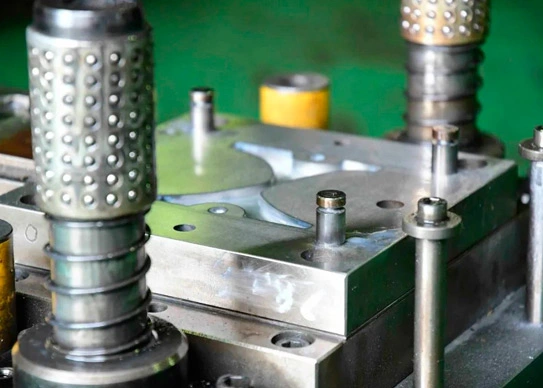

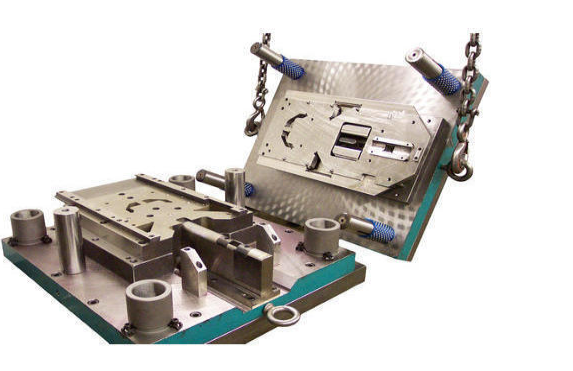

2. Compound Stamping Dies:

Compound stamping dies contain numerous operations or features within a single die set. These dies are more sophisticated than single dies and are utilized to create things with intricate calculations or that require many framing and cutting stages. Engineers use compound dies normally in high-accuracy applications where severe tolerance and complex structures are required. However, compound stamping dies are not perfect for forming operations like bending.

Compound stamping dies support proficiency by consolidating various tasks in a single device, diminishing the number of required arrangements and handling. They are broadly used in various industries, for example, auto, aviation, and electronics, which require precise and complex parts. Following are a few instances of compound stamping dies:

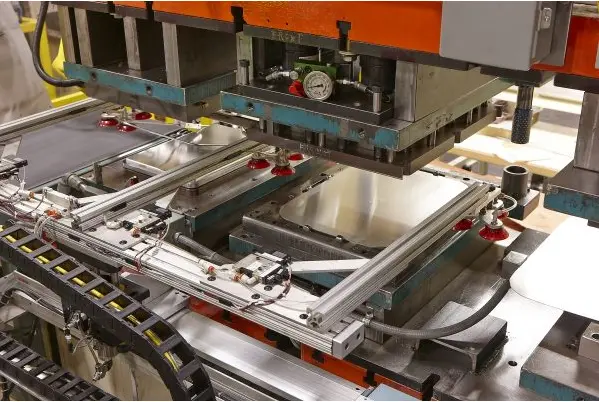

3. Combination Stamping Dies:

Combination stamping dies, in some cases called compound dies, are instruments that join different tasks into a single die set. The purpose of these dies is to coordinate several metal stamping processes, usually with a single press stroke. Combine dies are adaptable and can perform blanking, forming, cutting, and different features.

Combination die stamping vs single die stamping: Mix dies enjoy a few upper hands over different single dies for each activity, including higher productivity, lower tooling costs, and short creation cycles. They are especially valuable for creating complex and sophisticated parts along with other features and highlights, and they are utilized in different fields, including auto, aviation, electronic, and appliance manufacturing. The following are a few instances of combination stamping dies:

Blanking and Piercing Die

Forming and Trimming Die

Drawing and Piercing Die

Progressive Combination Die

Embossing and Bending Die

Curling and Notching Die

Coining and Piercing Die