Arc Welding

Arc welding or electric arc welding is one of the two basic metal welding processes. The process involves heating, melting, and joining metal sheets using an electric arc. The arc is developed using an electrode and electric current that flows from electrode to the metal sheets and back to the welding machine.

The electrode used in the arc welding may or may not be a consumable electrode. Mean it may or may not melt during the welding process. Consumable electrodes are usually used when there is a gap between plates to be filled.

MIG Welding

MIG welding or metal inert gas welding is a type of arc welding and is one of the most used sheet metal welding processes. This process provides very high quality and high strength weld joints and thus is used in high load applications.

In MIG welding metal sheets are heated, melted and joined together using a metal consumable electrode in the presence of an inert gas. A consumable electrode is fed through a gun and an inert gas usually argon shields the welding spot.

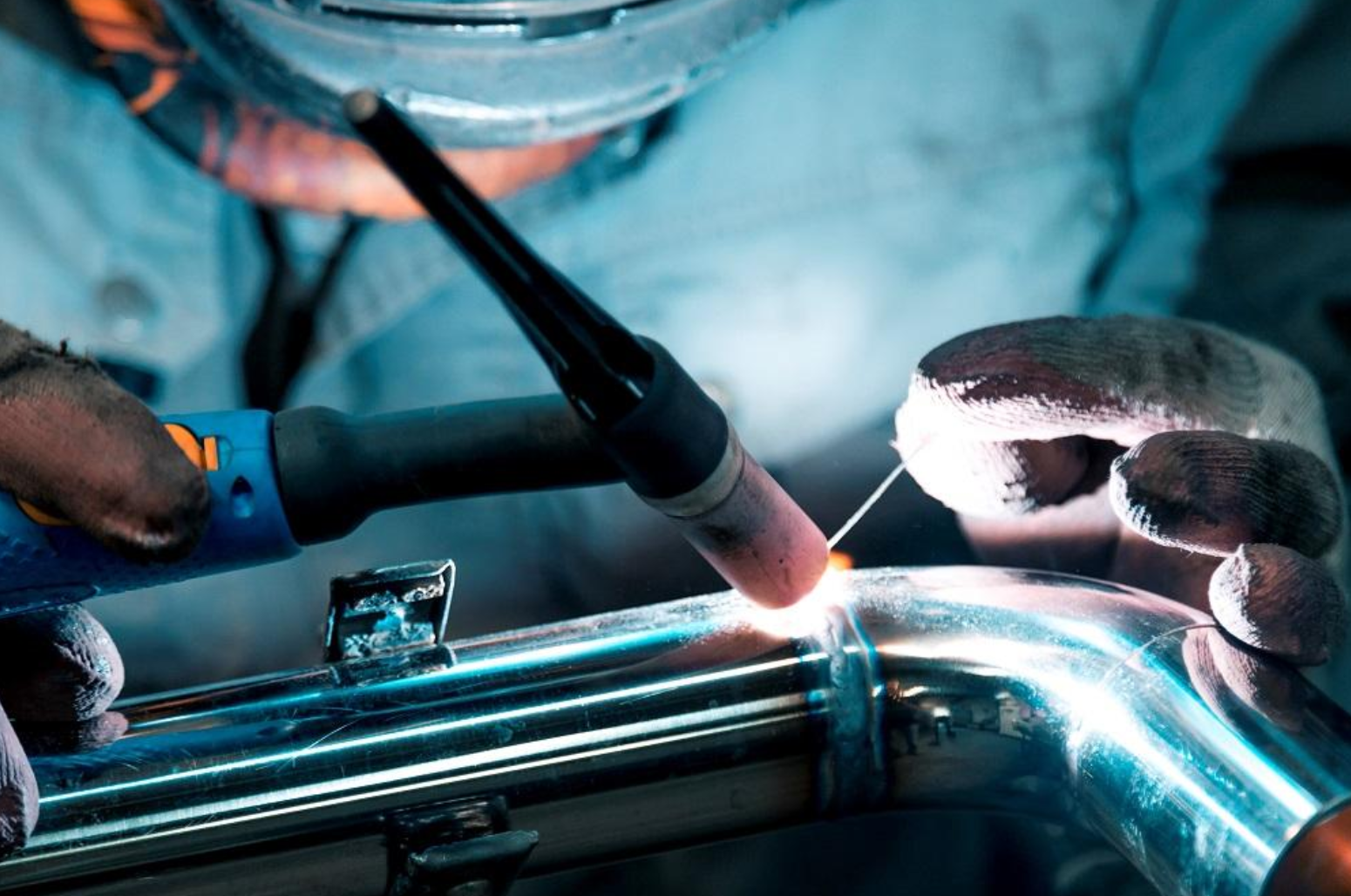

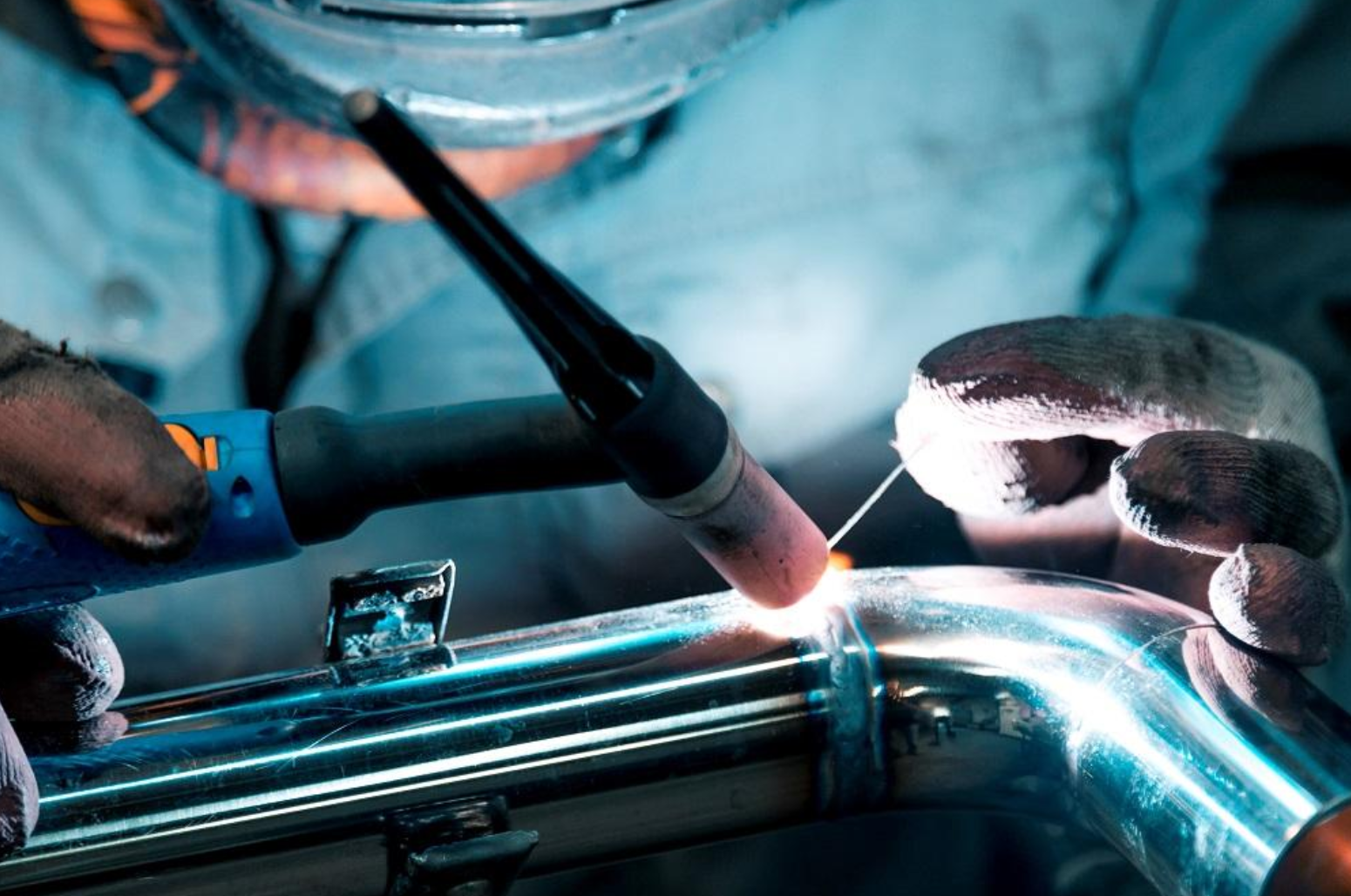

TIG Welding

TIG welding or tungsten inert gas welding is a type of arc welding and is also one of the most used sheet metal welding processes. Like MIG welding, TIG welding also provides very high quality weld joints.

In TIG welding, metal sheets are heated, melted, and joined together using non-consumable tungsten electrodes. A separate filler rod is used using this sheet metal welding process. The welding spot is shielded using an inert gas.

Spot Welding

Spot welding is another type of arc welding that produces a unique type of weld joint. It produces a weld joint that joins the metal sheets at only one spot at a time. That is the reason this process is called spot welding.

It uses a set of copper electrodes and electric arc to heat, melt, and weld the overlapping metal sheets. This process is used to weld a thin metal sheet for low load applications.

Seam Welding

Seam welding is another type of arc welding that is very similar to spot welding. Seam welding uses two copper wheels as electrodes. It heats, melts, and joins the overlapping metal sheets using electric current.

Seam welding, unlike spot welding, is used to produce a continuous seam of welding. That is the reason it's called seam welding. It is also used to weld thin sheets of metal that can be used for low load applications.

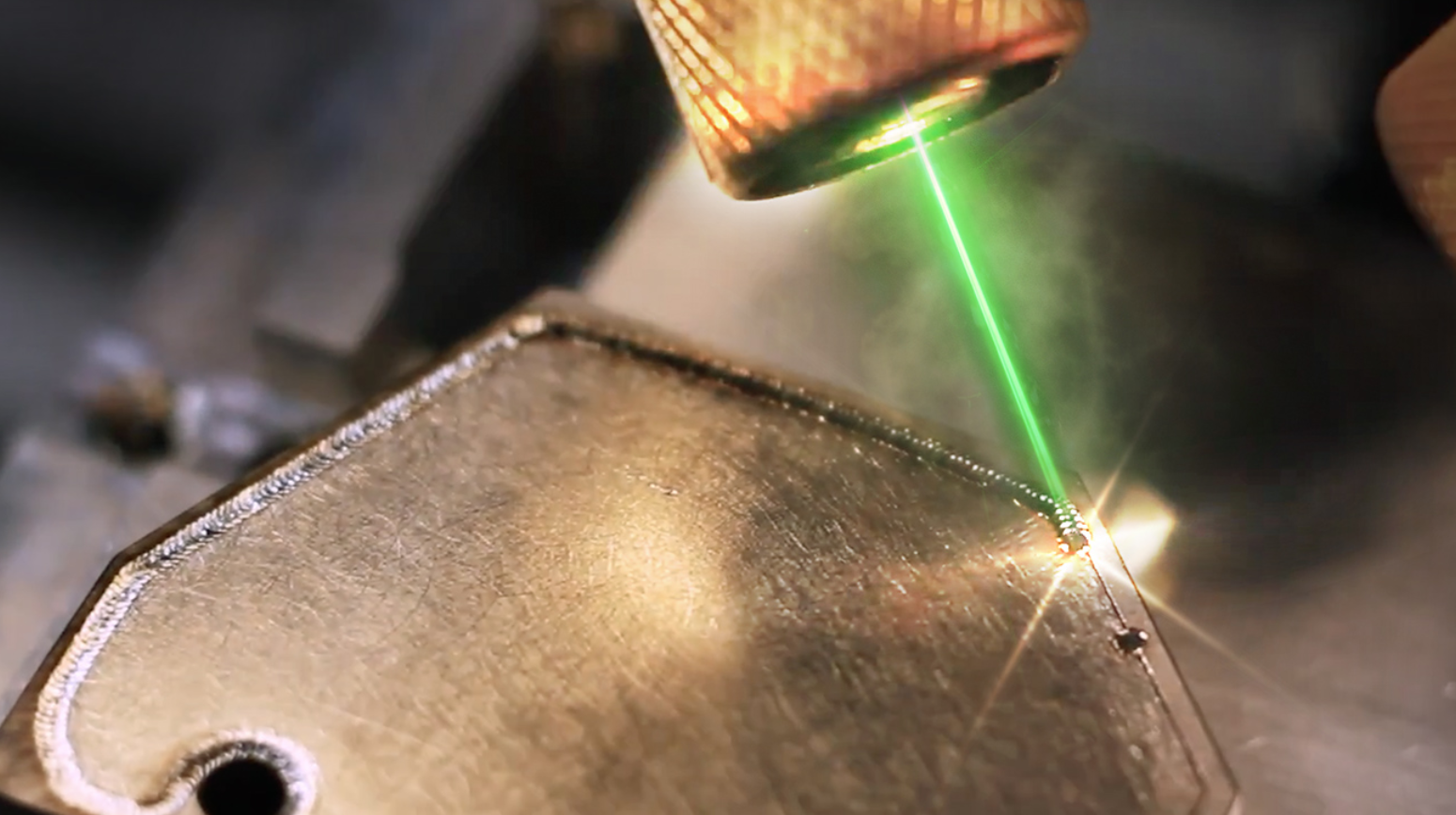

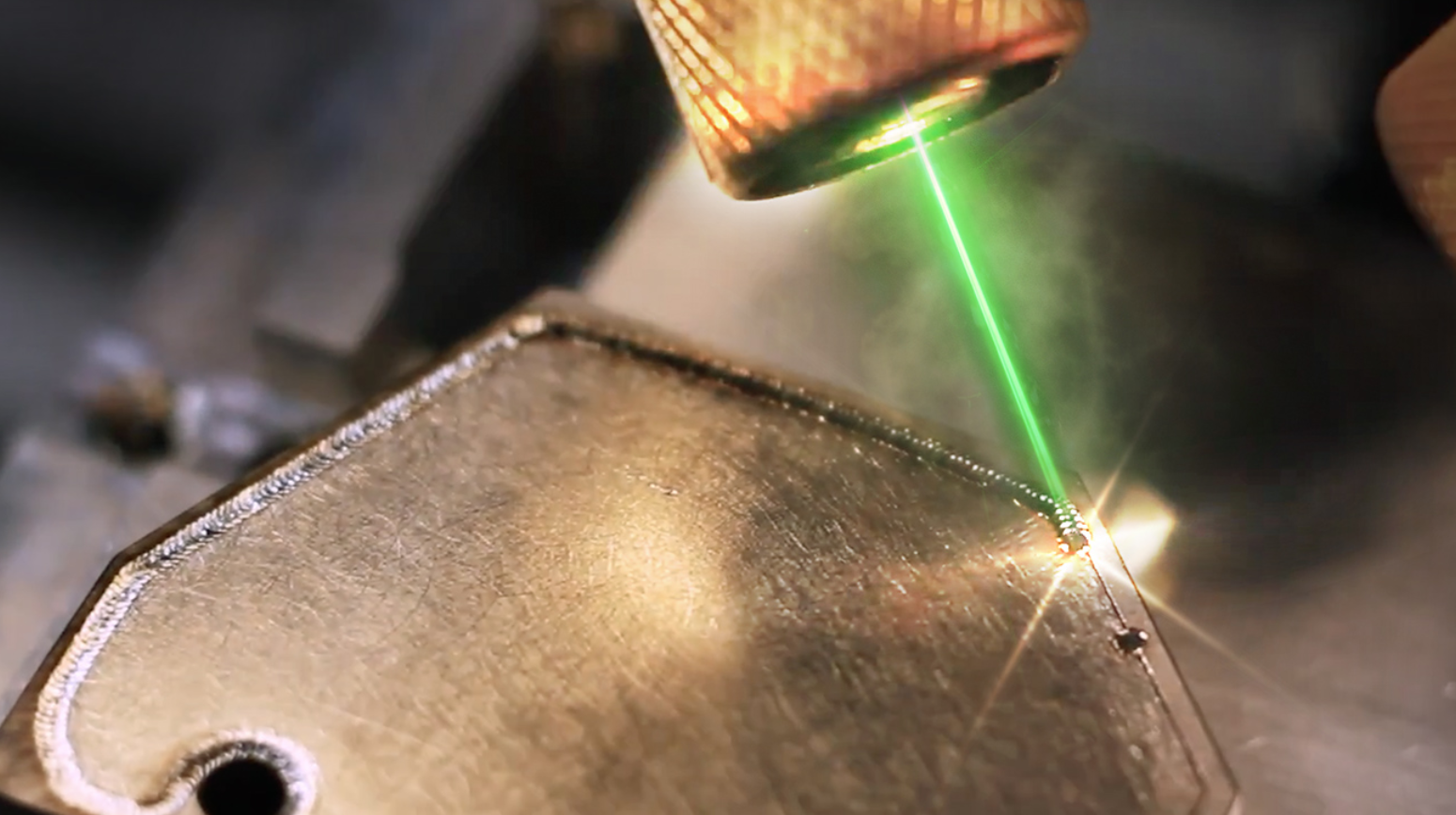

Laser Welding

Laser welding is a type of sheet metal welding where two thin sheets of metal are welded together using a laser beam. Laser beam in laser welding, heat, metal and join the metal sheets.

This process can be done on a very thin sheet which other processes might not be able to do. This process also provides a very high precision welding thus producing very high quality products.