With rich experience in all the spoken techniques, we summarize the design tips from our past experiences in over hundreds of projects. Here you can find some brief items when we are designing your sheet metal products or what needs to be reviewed with your sheet metal suppliers.

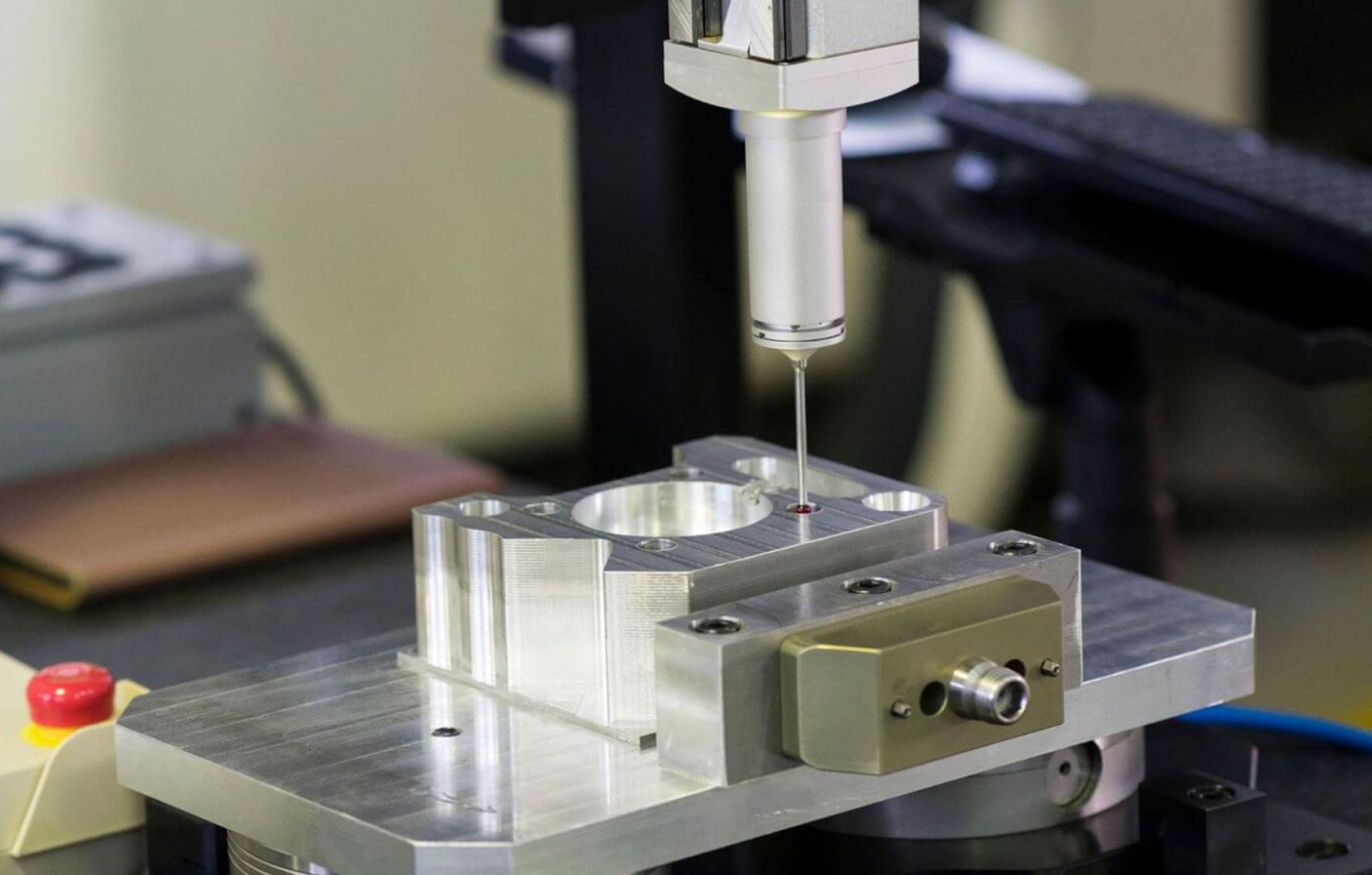

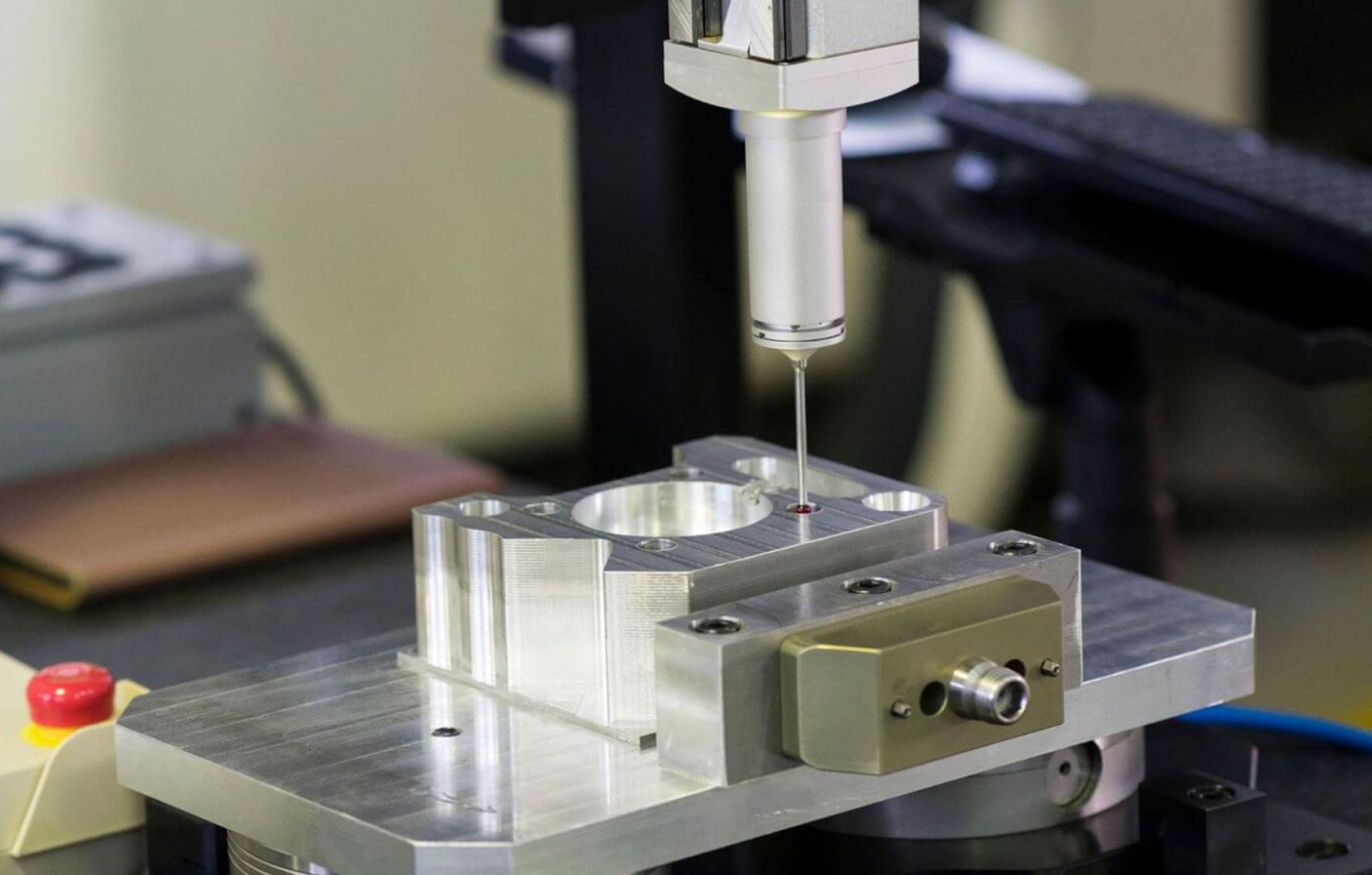

Dimension and Tolerancing

Engineering designers put a lot of time in specifying the callouts on their drawing. In addition to the labeling work on paper, they also need to have a deep understanding of the processing capabilities of different techniques and the repeatability of different equipment. These factors have the most significant impact on product dimensions and tolerances. A high-precision machine can produce products over 10 times more precisely than a relatively poor one. Moreover, different precision annotations directly affect the cost of the product. Indicating a precision that is challenging to achieve can lead to a geometric increase in product costs, which is a risk designers need to avoid.

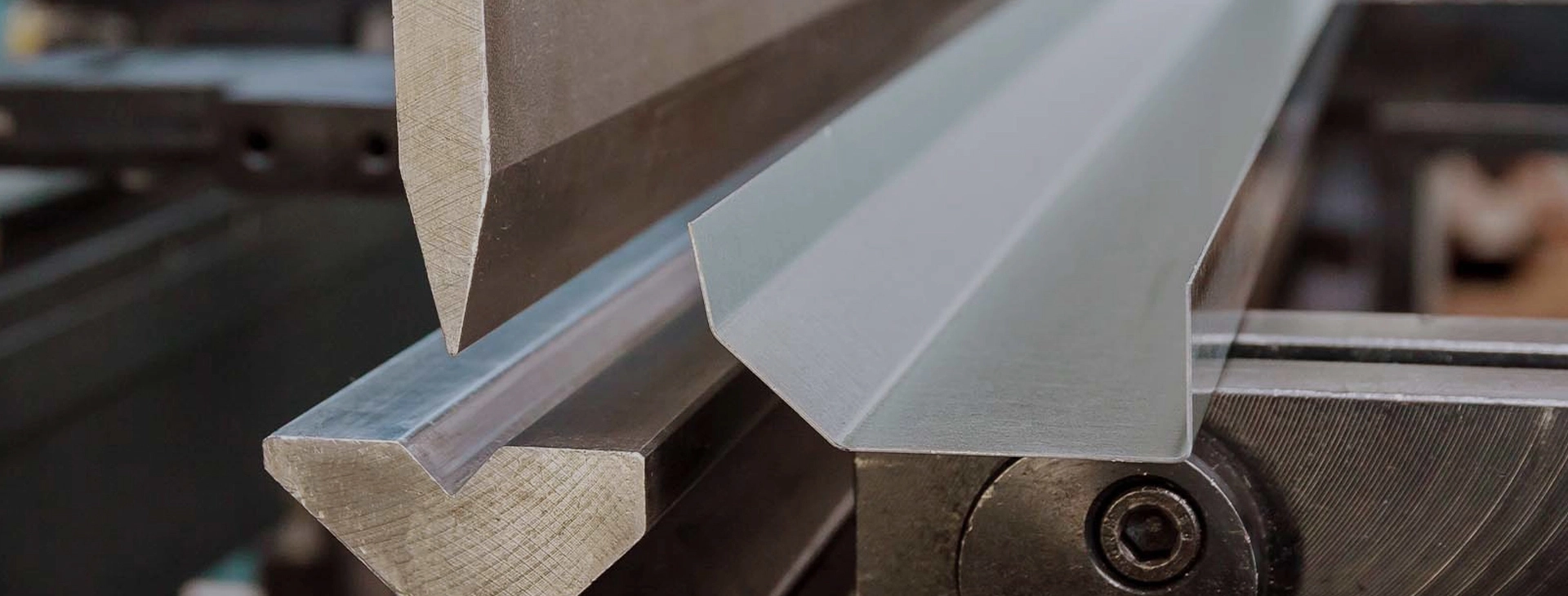

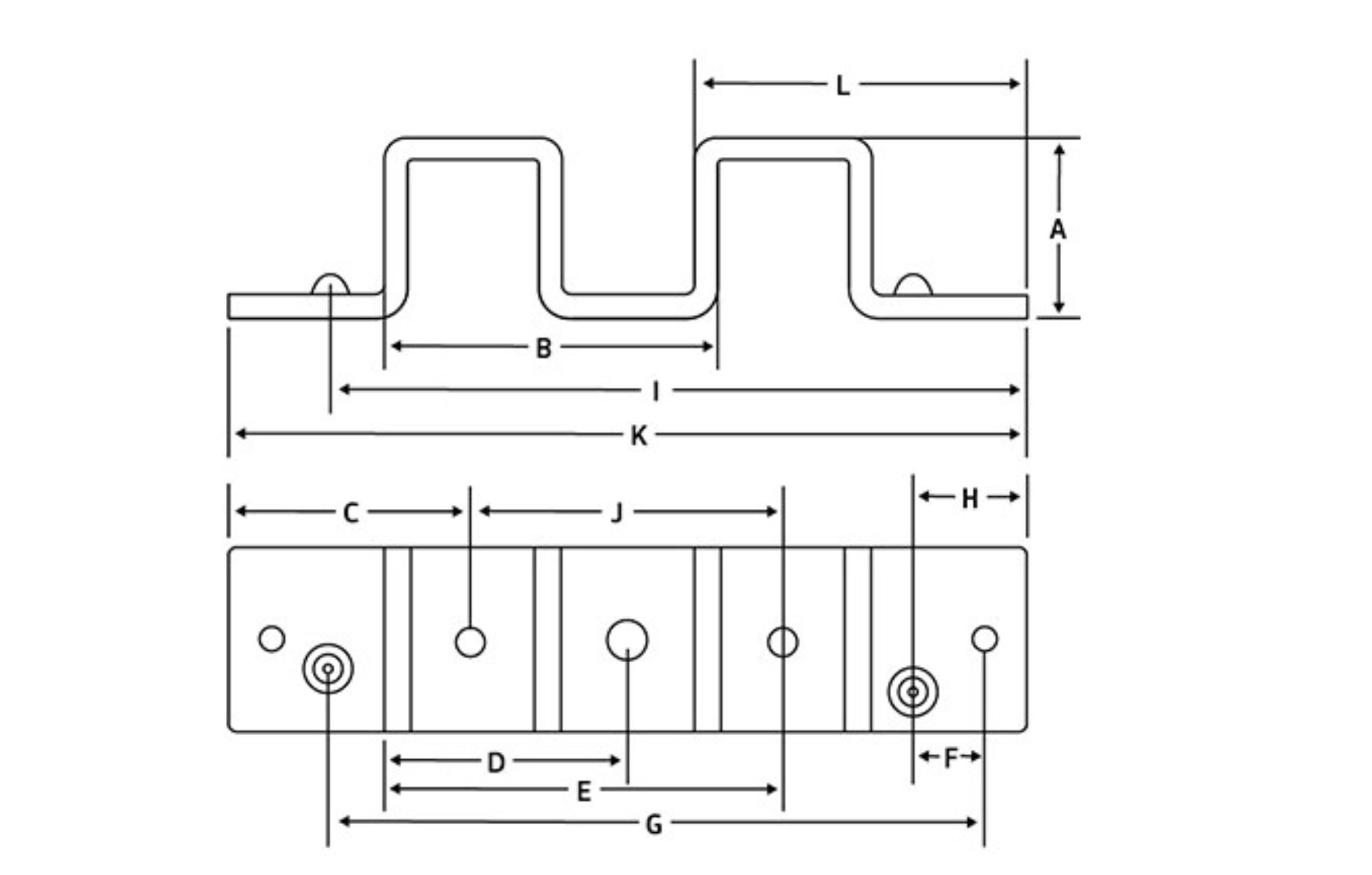

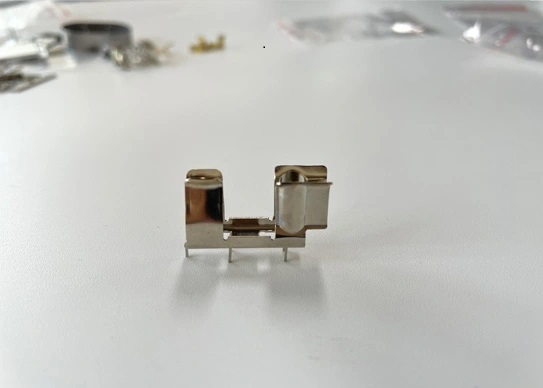

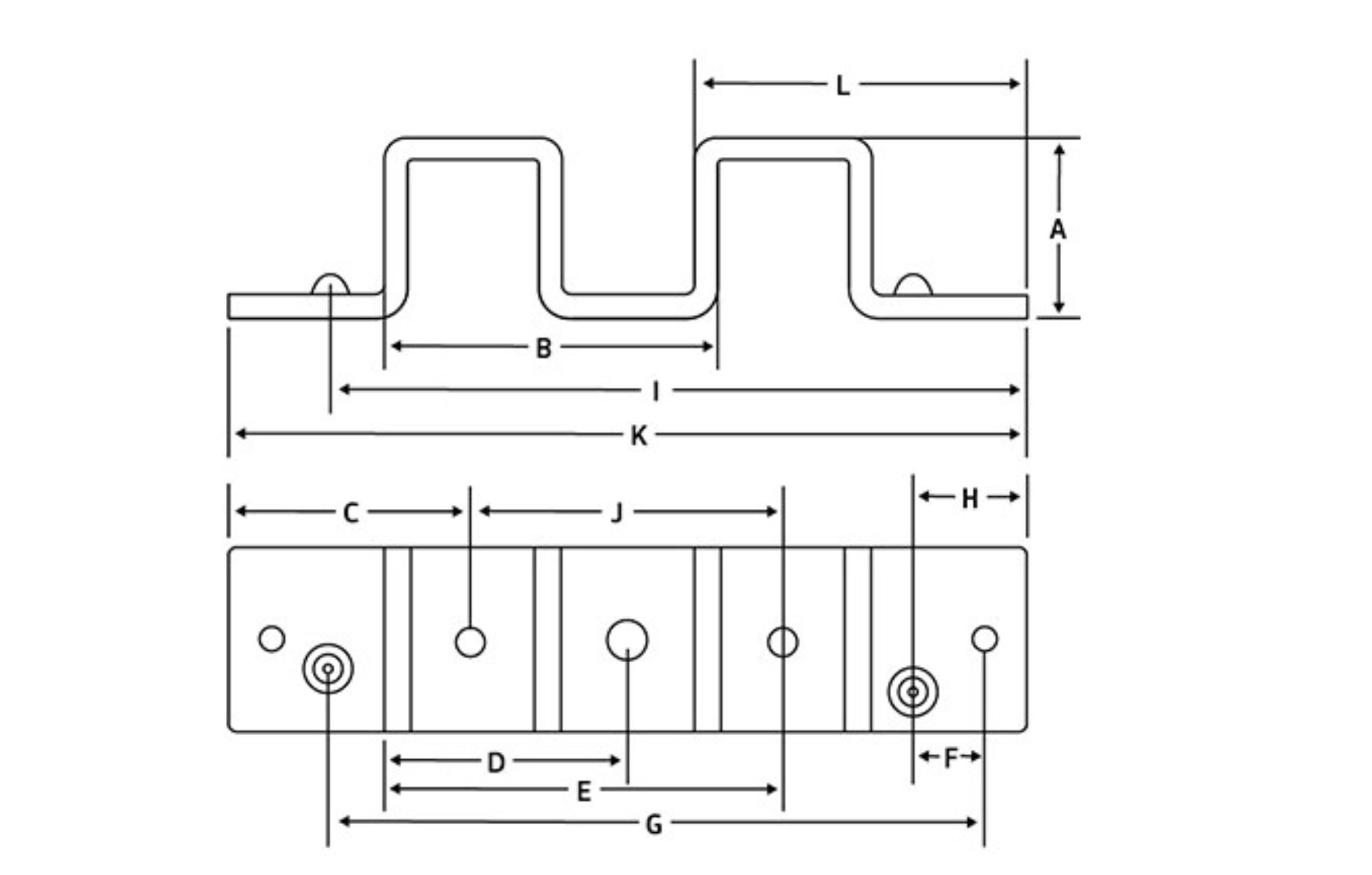

Structures and shapes

There are common principles in sheet metal fabrication, designers should be aware of some vital structures that would deeply affect the quality and cost of final parts. They are distance such as bending radius, bending direction, bent relief, spacing and distance between tabs and notches, holes and slots, flanges and chamfers, also the size of embossed and countersink features is another important shape that needs to be taken care of. If you are familiar with different design specifications and annotation methods, it will greatly speeds up the design process, reducing your potential errors and repetitions.

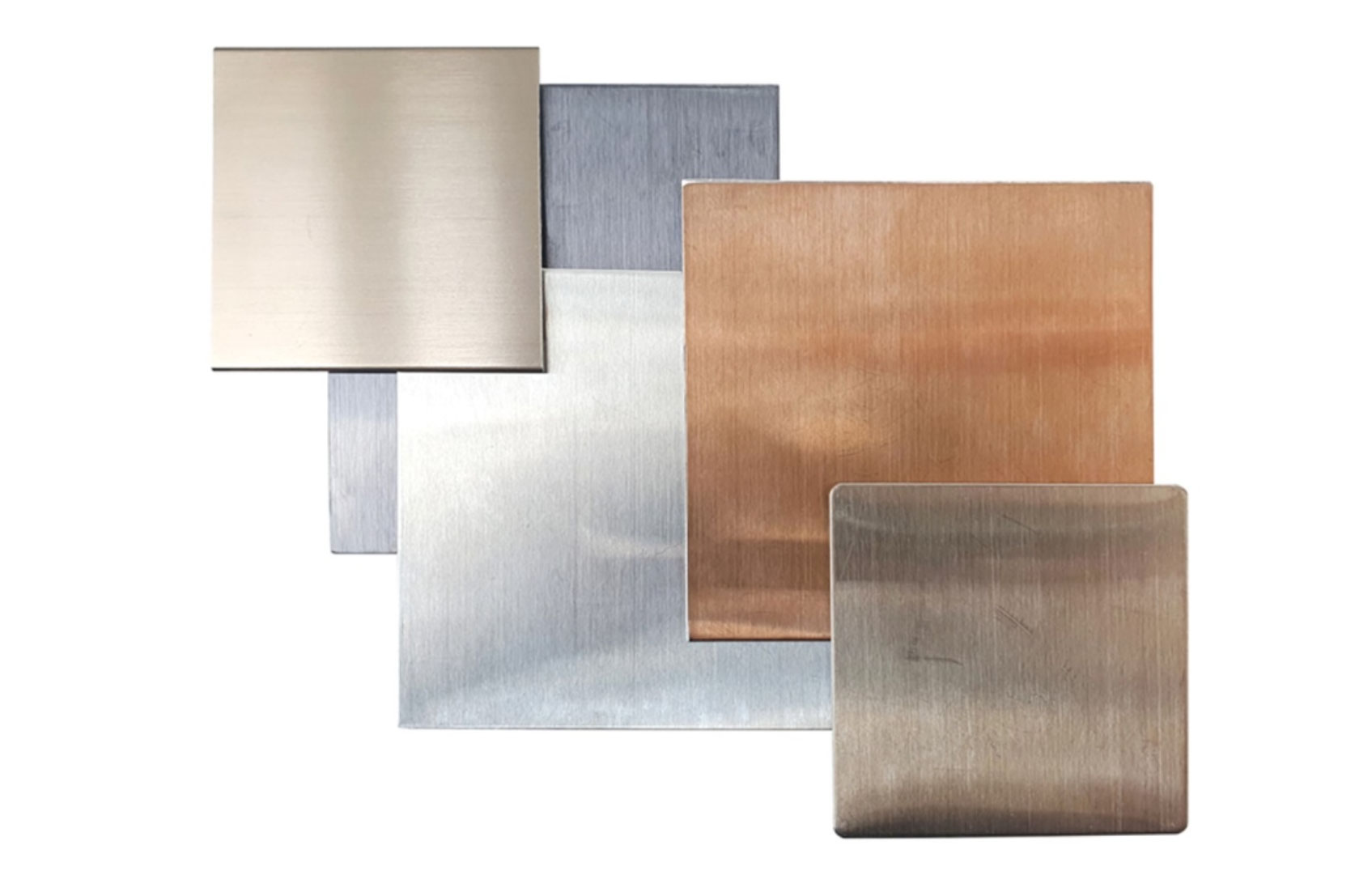

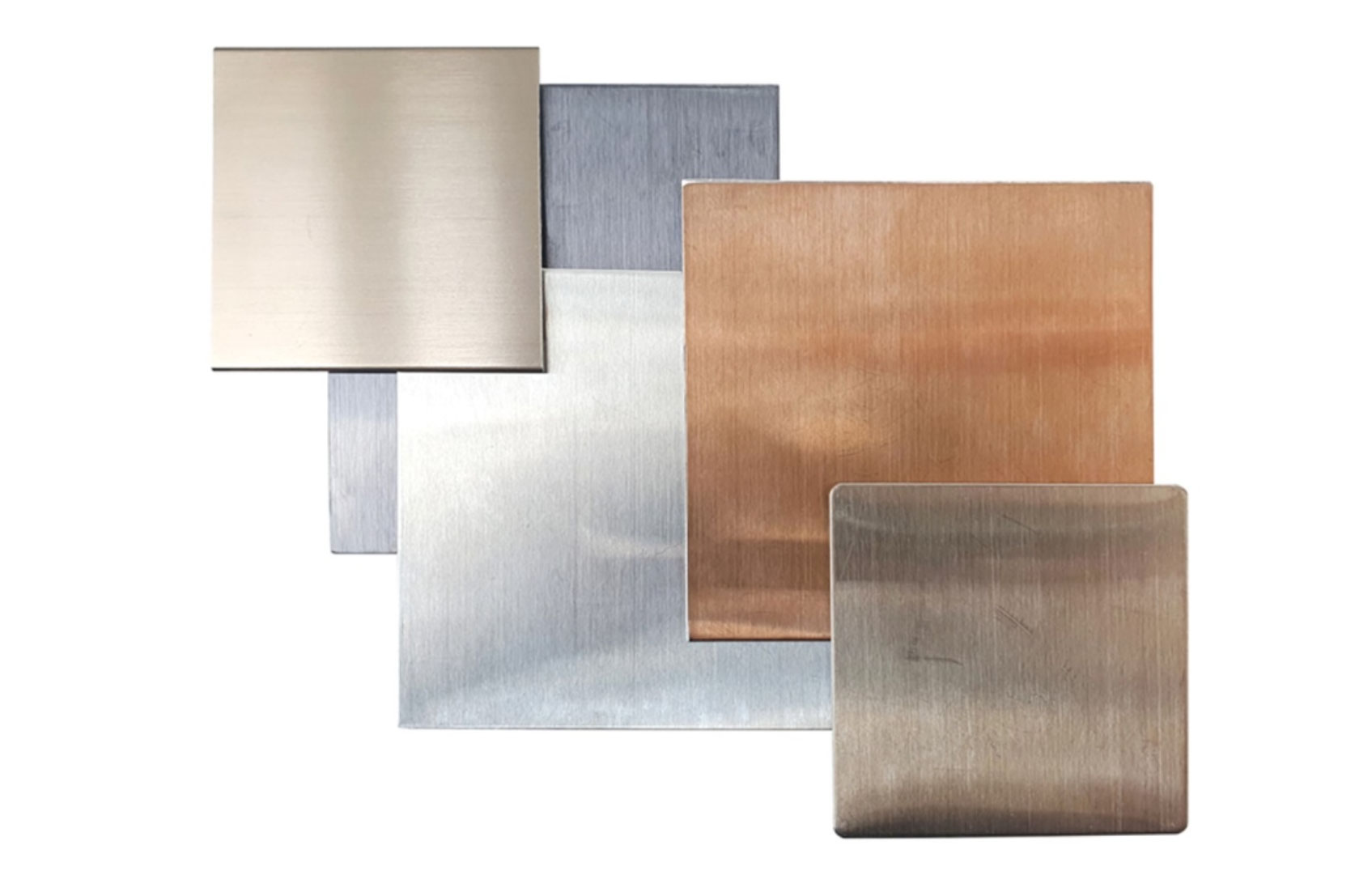

Materials and Finishes:

There are thousands of different materials on the market. We need to consider the product's requirements, starting from the basic properties of the material, combining its processability, availability, and unit cost for comprehensive considerations. Additionally, different specifications for materials can greatly affect costs. Different countries often have different specifications, and designers need to understand different country systems to make the most suitable choices based on their location, reducing the difficulty of obtaining materials.

Quality and Testing:

Finally, designers need to consider a comprehensive quality control plan. Don't think this is the job of quality engineers; designers also need to consider this aspect during the design phase. Especially in setting up the testing content, a well-established testing plan during the initial sampling stage can significantly reduce product risks, ensuring stable performance after large-scale production. These testing plans often include environmental testing, strength testing, performance testing, fatigue testing, and more.