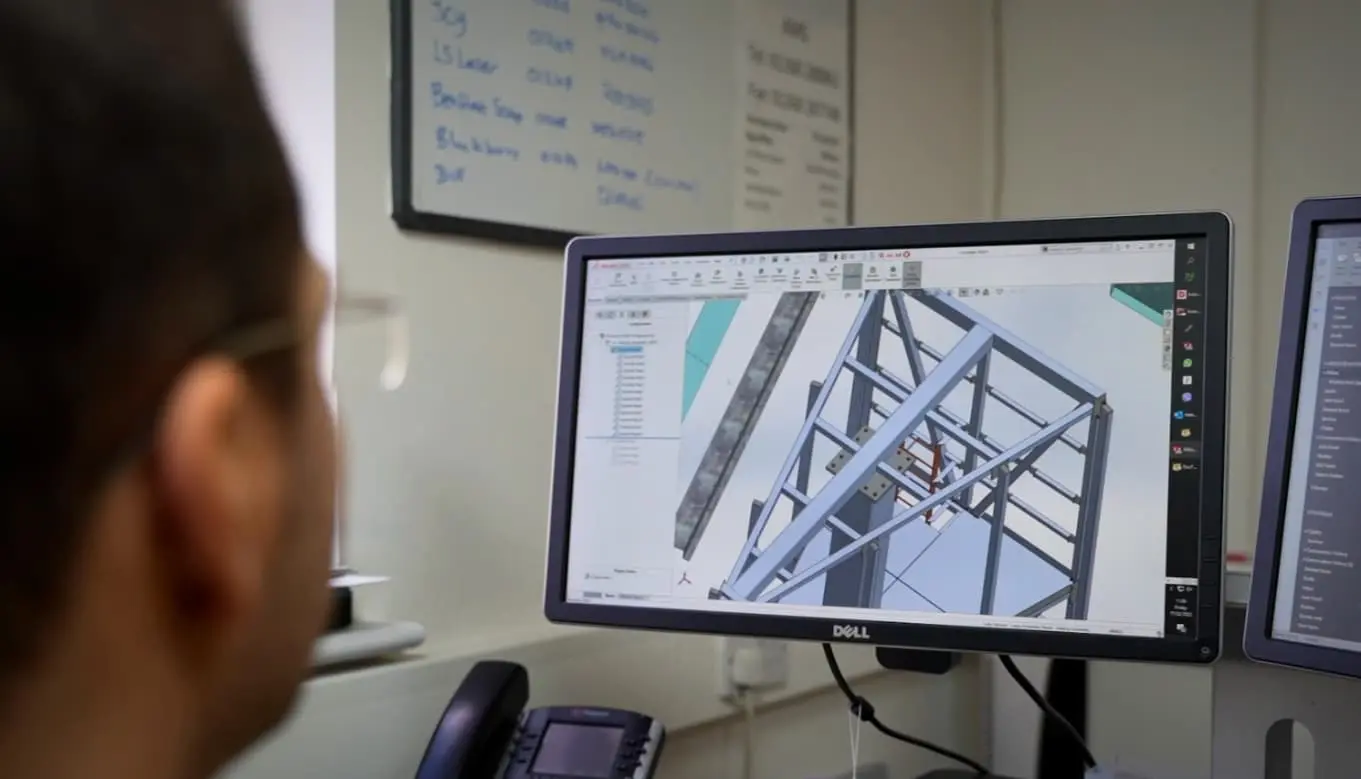

Sheet metals for fabricating metal enclosures and cases through sheet metal fabrication offers several advantages. That’s the reason that makes it a popular choice in various metal fabrication industries like JCL.

Durable and Sturdy

The first and best advantage of having a sheet metal enclosure is the strength, durability, corrosion resistance and sturdiness you get from metals. Metals like steel and aluminum give excellent durability and sturdiness.

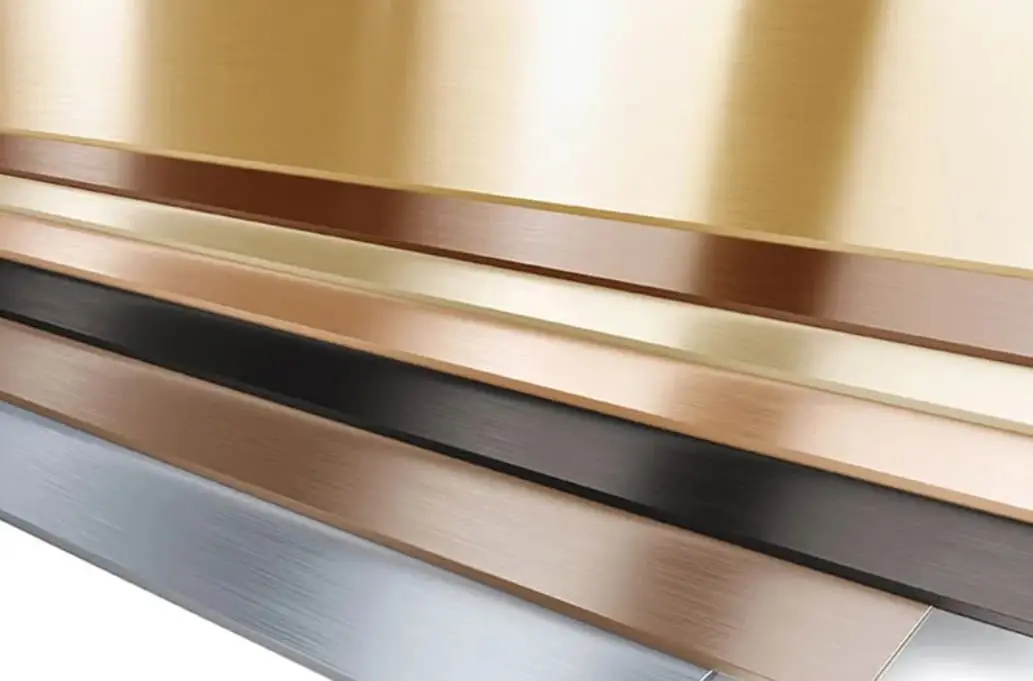

Wide Range of Materials

Sheet metal offers a wide range of materials like aluminum, aluminum alloy, mild steel, stainless steel, alloy steel and many more. All these materials are widely available and are easy to transport and maintain.

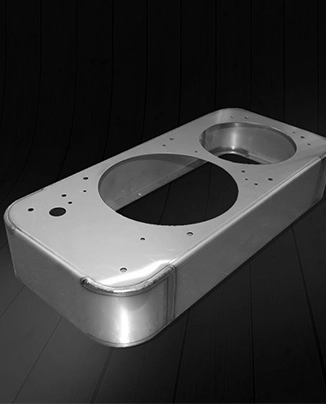

Security and Protection

Sheet metal enclosure provides an excellent security and protection specially to electronics products. Due to metal strength, hardness and toughness the products inside the enclosure and casing are protected against all external forces. Metal enclosures for electronics are the best options for electric products.

Recyclability

One of the biggest advantages of sheet metal is their recyclability. After the product has gone its useful life, the material can be recycled to directly make any other product or can be melted and used for manufacturing new metal sheets.

Cost Effectiveness

Sheet metal enclosures are much more cost effective than plastics and other materials. This is due to the fact that sheet metal tooling cost, production cost and product useful life makes the metal enclosure much more cost effective than other materials enclosures.