Sheet metal covers and caps have various applications in different industries. Their versatile use is due to their durability, versatility and protective qualities. Few examples of sheet metal covers and caps applications in different industries are.

Construction Industry

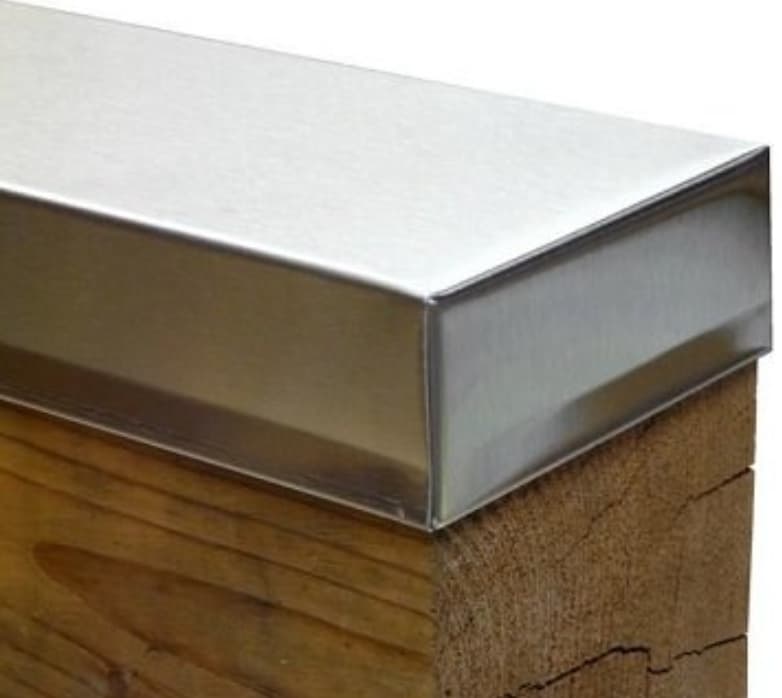

Sheet Metal Beam Caps

Sheet metal beam caps are widely used in construction and it is one of the biggest applications of sheet metal covers and metal caps.

These covers and caps designed for individual beams are applied to the ends of structural beams to protect them and do reinforcement.

These caps shield the beam ends from environmental elements like rain and prevent corrosion. These caps also add structural integrity and also increase aesthetic appeal to the construction.

Column Caps

Sheet metal column caps are just like beam caps and are used to protect the tops of vertical building supports called columns. These caps help prevent water ingress. This is crucial for maintaining the structural integrity of columns in different construction projects.

Connector Plates

Sheet metal connector plates are used to join wooden trusses or beams. These plates are hollow with cross sections depending on the shape of the wooden beam or truss to connect. These plates provide stability and prevent separation between the connected members.

Roofing Industry

Roof Flashings

Sheet metal caps made of materials like aluminum and galvanized steel. They are used for roof flashings. Roof flashings are areas where the roof meets a vertical surface. They are also installed around roof penetrations like around chimneys or around vents. Roof flashing prevents water leakage and also enhances the overall waterproofing of the roof.

Ridge Caps

These are used at the peak of a sloped roof to cover the joint where two roof slopes meet. Ridge caps prevent water infiltration, protect against wind-driven rain, and contribute to the overall aesthetics of the roofing system.

Industrial Applications

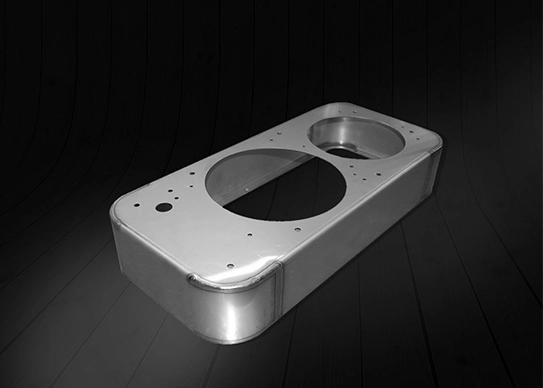

Equipment Caps

Sheet metal caps can be used to cover and also protect different equipment and machinery. Caps help prevent dust, debris and moisture from entering critical components. This ensures the longevity and reliability of the equipment.

Pipe Caps

Metal caps are also used to close the ends of pipes in different industrial applications. This protects the pipe ends from damage and also prevents the entry of contaminants into the pipes.

Duct Caps

In heating ventilation and air conditioning systems metal caps are used to cap the duct ends. This ensures that the duct remains closed. This prevents air leak and also maintains the efficiency of the HVAC system.