Reverse deep drawing process has applications in various industries. It is used to draw complex shapes with high precision and quality. Some common applications include.

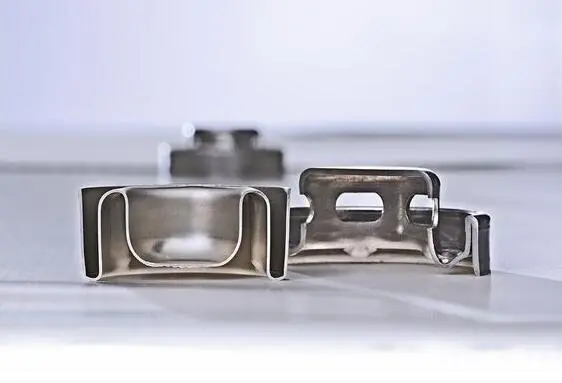

Automotive Industry

Reverse deep drawing process can be utilized in the automotive industry for part manufacturing. It can be used for drawing components such as complex shaped custom fuel tanks, custom exhaust systems, airbag housings and other structural components. All these parts usually require intricate geometries with tight tolerances. This can only be achieved effectively through a reverse deep drawing process.

Aerospace Industry

In the aerospace industry, reverse deep drawing is employed for fabricating parts and different engine components. These components include custom engine housings, special ducting systems and different structural elements used in the aerospace industry with complex shapes and lightweight designs. The deep drawing process allows for the production of the parts in a manner that meets stringent performance and reliability requirements.

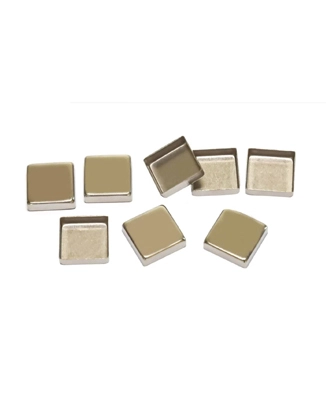

Consumer Electronics

Reverse deep drawing process can be used for the production of several consumer electronic devices. These devices include mobile phone housings, camera bodies, and audio equipment enclosures. The deep drawing process enables manufacturers to draw sleek and compact designs with very high precision over dimensions and deliver smooth surface finishes.

Medical Devices

For the medical device industy, the reverse deep drawing process can be used to manufacture different components. These include surgical instrument casings, different implantable device housings and different diagnostic equipment enclosures. The deep drawing process ensures the production of high quality sterile and biocompatible parts. Deep drawing processes also ensure intricate features for medical applications.