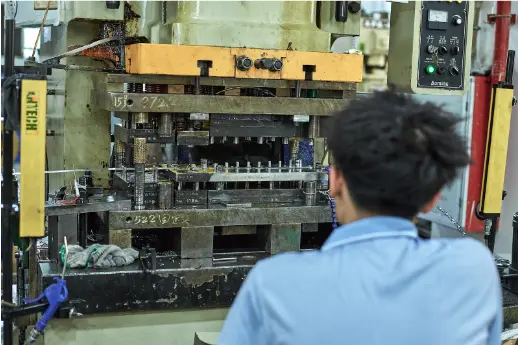

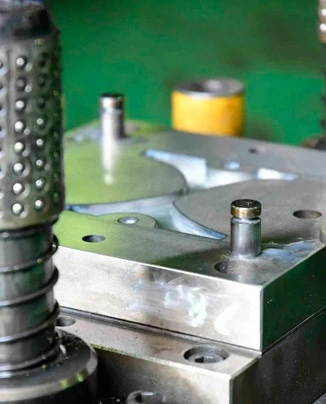

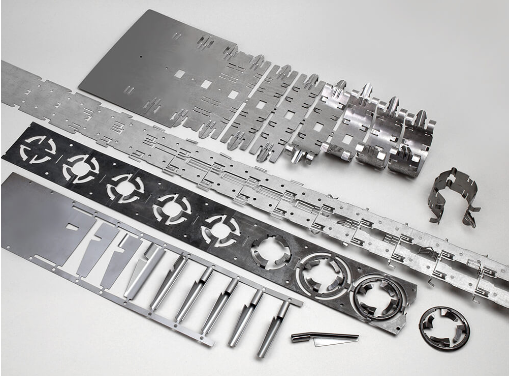

JCL’s Progressive Die Stamping Solutions for Diverse Industries

JCL has significant experience not only in design but also in manufacturing complex metal parts by utilizing progressive stamping processes for various sectors. Don’t forget, that quality is our primary concern. Our mechanized checking technique guarantees tolerance requirements, and steady precision, diminishes waste, and saves you money. We proudly serve a diverse range of industries, including:

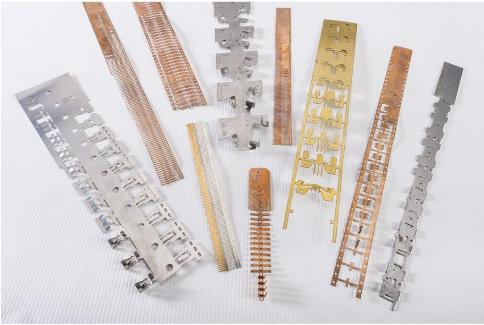

Electronics:

From sturdy chassis to sensitive connectors (USB Type-C connectors, memory card sockets, battery covers, circuit board shields, Smartphone cases, springs, heat sinks, and camera modules), we make trustworthy and exact parts for the constantly changing electronic scene.

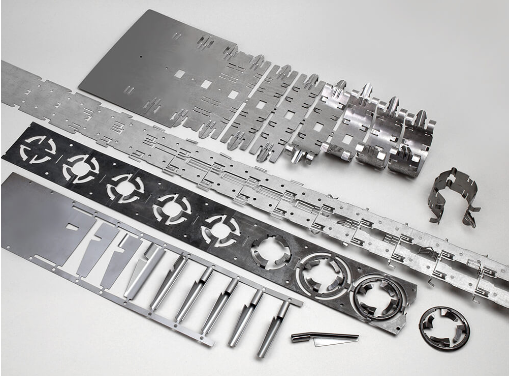

Automotive:

From security basic guiding parts ( hoods, fenders, trunk lids, fuel injectors, spark plug holders, Seat belt buckles, door locks, gear shift levers, window regulators, Valve covers, etc.) to complex inside subtleties, we utilize exact and reliable metal parts to characterize the eventual fate of versatility.

Electronics for Consumers:

From fundamental kitchen machines to state-of-the-art gadgets (power tool casings, drill bits, handles, brackets, remote control buttons, speaker grilles, screwdriver tips, wrench heads, brackets, housings, and blades), we rejuvenate new designs through proficient and practical manufacturing.

Medical Gadgets:

We grasp the crucial idea of medical products (clamps, retractors, probes. bone screws, plates, joint replacements, blood glucose meters, insulin pumps, Dental implants, forceps, etc.) and give high-accuracy parts that satisfy the most severe quality and security guidelines.

Telecommunications:

We add to worldwide availability by empowering the assembling of trustworthy and communication metal parts (Mobile phone antennas, RF connectors, fiber optic connectors, router casings, smartphone backplates, Cable connectors, Wi-Fi antennas, and GPS antennas).