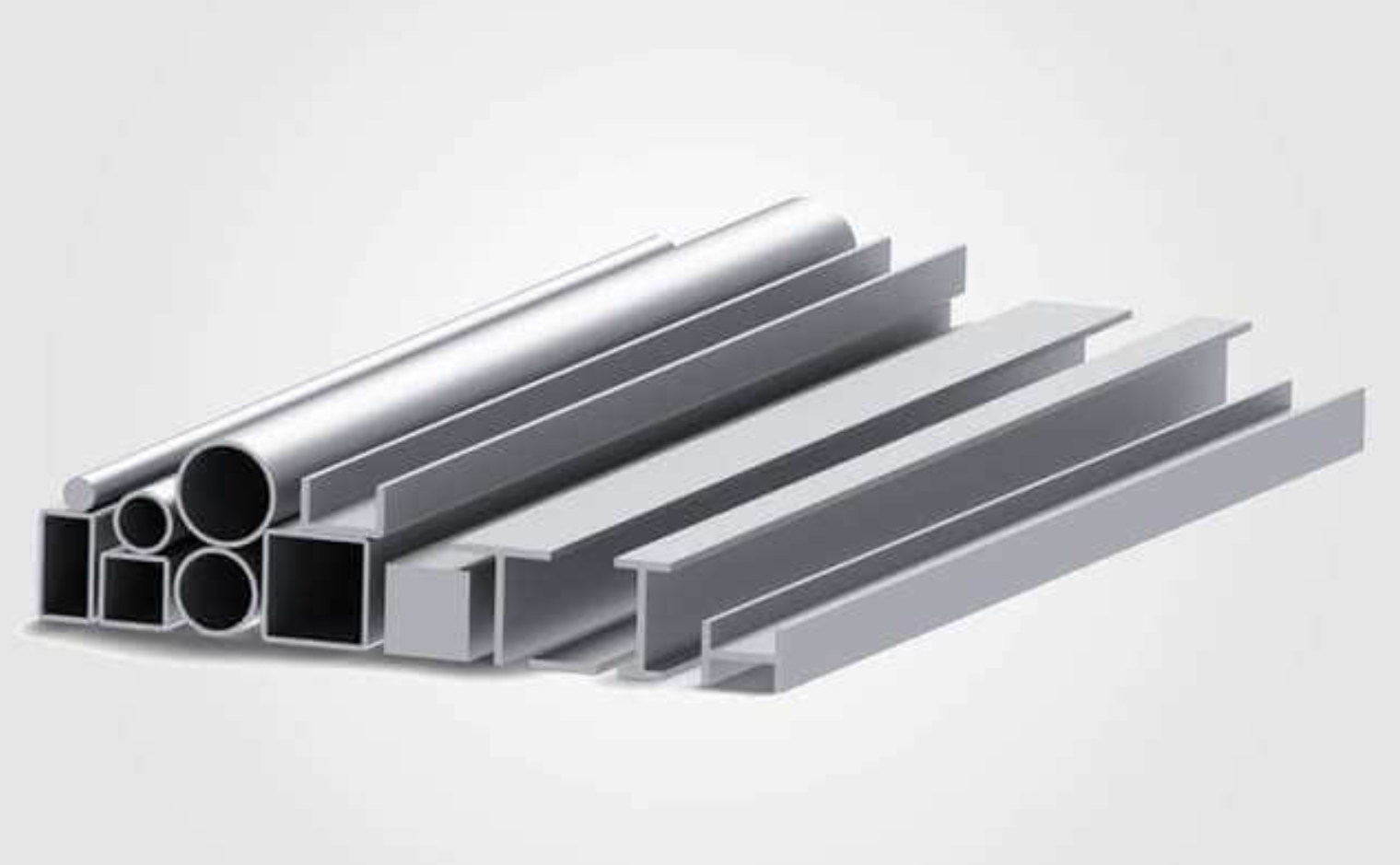

In the metal extrusion process there are several categories of metal extrusion profiles. This is done to make it easy for manufacturers and clients to communicate. Some common categories includes,

Solid Profiles

Metal extrusion solid profiles have a uniform cross section area. They offer simplicity and structural integrity in the final product.

Rods and bars are examples of solid profiles. Solid profile in metal extrusion is mostly used for cost-effective manufacturing during mass production.

Hollow Profiles

Hollow profile in metal extrusion features enclosed voids. In the manufacturing industry this process is known for its optimized material usage while maintaining strength.

Some common applications of this process are in aerospace and fluid transport systems. As hollow tubes offer a balance between strength and reduced weight. This increases overall efficiency in various applications.

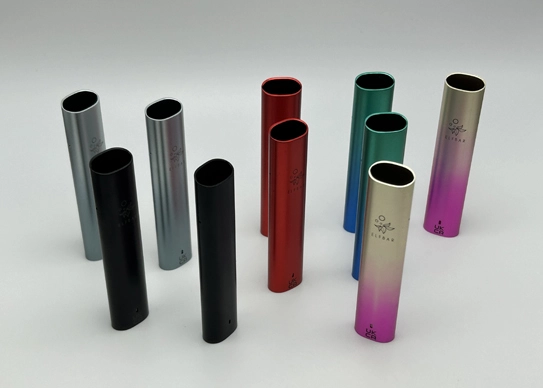

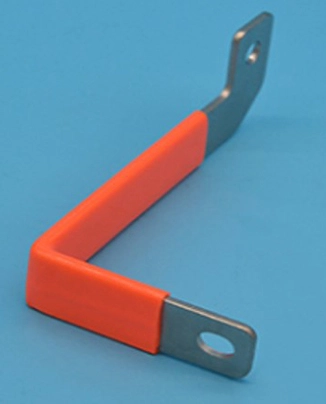

Complex Profiles

Metal extrusion processes can also process complex profiles. This process not only produces these complex shapes but does it with great control over different design parameters.

Found in automotive and electronics, these profiles provide versatility. This allows the creation of custom components with unique specifications.

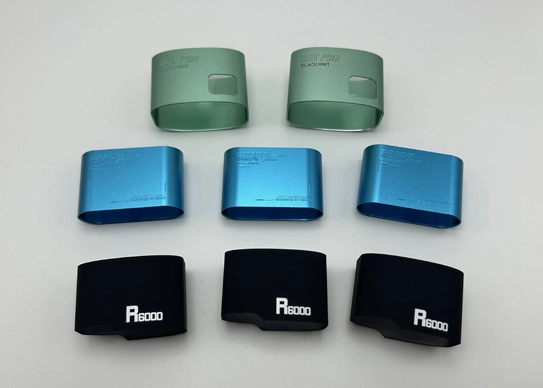

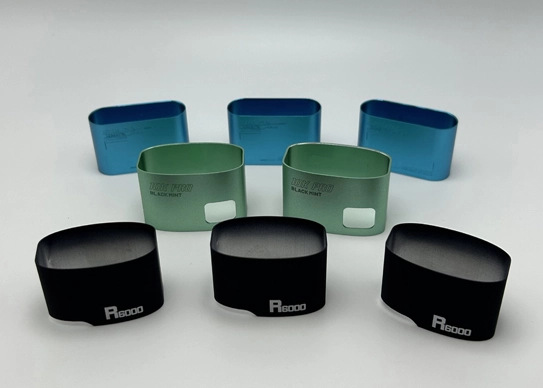

Thin-Walled Profiles

One of the most used profiles, the metal extrusion thin wall profiles is famous for its role in crucial applications that prioritizes weight reduction without compromising strength.

Thin wall metal extrusion profiles strike a balance between structural integrity and lightweight design. This makes them integral components in different engineering solutions.