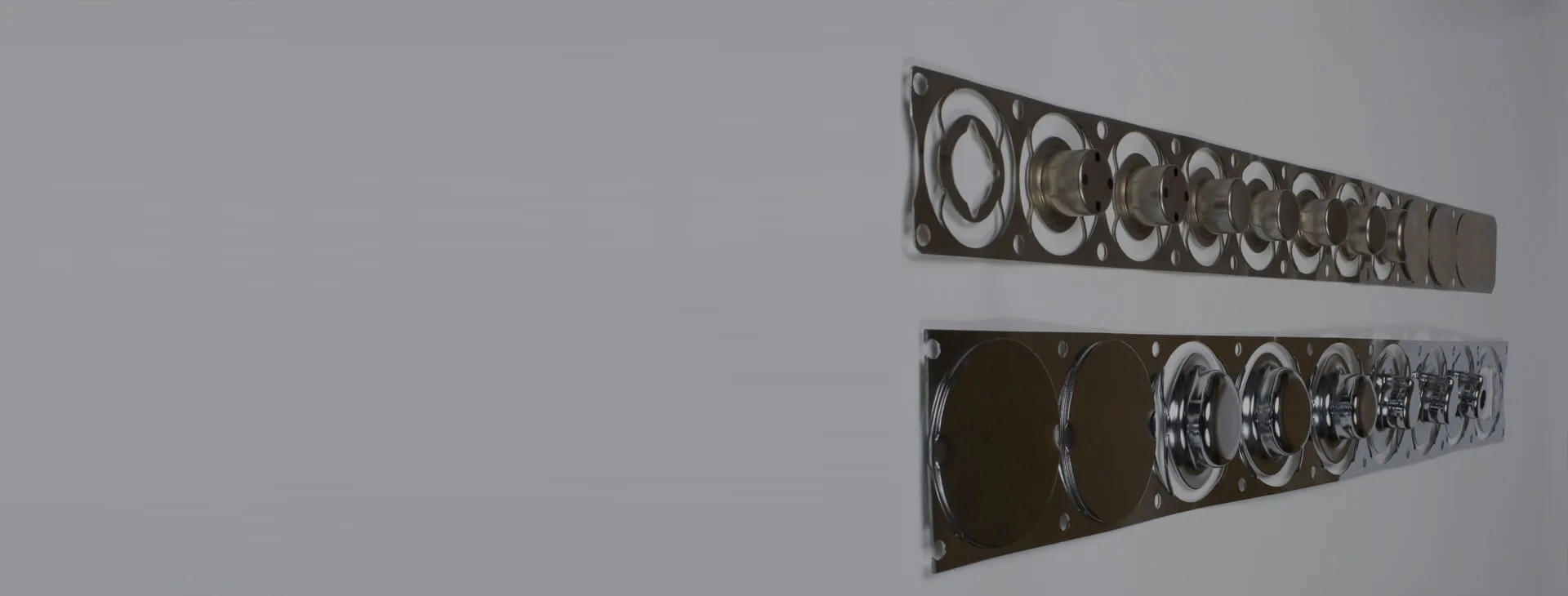

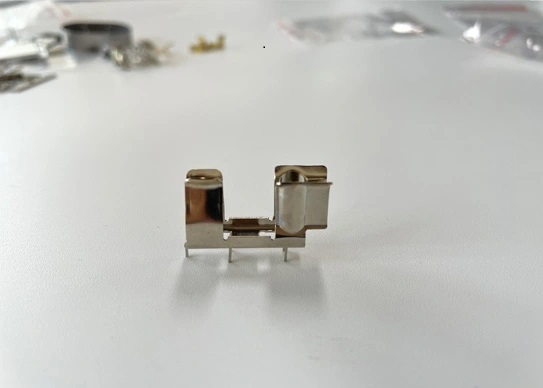

Offered Shapes: Basic shapes in round, square, rectangular, cylindrical, tapered, reversed, miniature are available.

Size in Length & Width: Minimum 3mm to Max. 450mm in diameter and 500 mm in blank length; Length can reach 50m in metal coils feeding.

Sheet Thickness: Common materials specification is 0.01 mm to 5 mm; Super thin foil forming available to achieve thickness below 0.01mm.

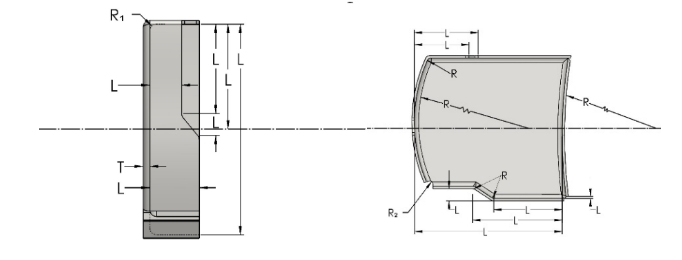

Operative Precision: Our minimum blanking tolerances can reach 0.03mm without extra machining; Profile tolerances are measured to 0.015 mm on ultra punching headers; Blanking radius can be as small as 0.1mm. Deep drawn corner radii can be minimized to the lowest of 0.1 mm.

Production Volume: low volume prototype to over 1000000 parts in automotive business and 5000000 parts in consumer electronic business.

JCL is able to manufacture parts within these specifications, offering excellent quality and effective cost. We are driving deep drawing technology into a manufacturing method that allows for efficient production used in various industries.

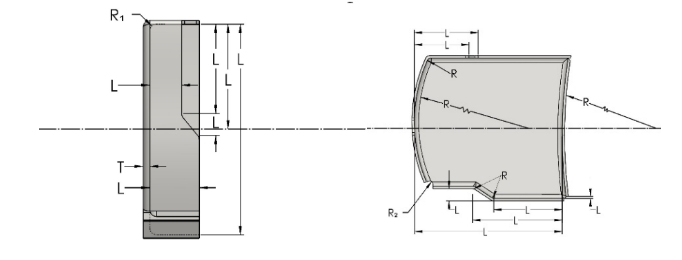

Quality Inspections of Deep Drawn Shapes

Here are some typical dimensions to measure, common measurement instruments are optical measurement machines and coordinated measurement machines. OMM is a way of non-contact measurements that uses the projection to reflect the distance of the parts. CMM uses a probe attached that can be controlled along the X, Y, and Z in 3D. The probe is positioned at different points on the object and the coordinated distances of these points are recorded.

FAQ

1. What are the common basic shapes that JCL specializes in for deep drawn parts?

JCL specializes in deep drawn parts with a range of basic shapes including round, square, rectangular, cylindrical, tapered, reversed, and miniature. These shapes cover a wide variety of applications and industries.

2. What is the maximum size in terms of diameter and blank length that JCL can handle?

JCL can handle deep drawn parts with diameters ranging from a minimum of 3mm to a maximum of 450mm. In terms of blank length, JCL can work with parts up to 500mm in length. For certain applications, JCL also has the capability to work with metal coils and feed lengths up to 50m.

3. What is the range of sheet thickness that JCL can work with for deep drawing?

JCL has the capability to work with sheet thicknesses ranging from 0.01mm to 5mm. Additionally, JCL is equipped to handle super thin foil forming, which allows for the production of parts with thicknesses below 0.01mm.

Collaborate With JCL for Your Material Solutions

As you may find JCL expertise in material solutions and forming shapes evaluations. We are capable of dividing your requirements into these high technical areas and you will feel easily with our assistance and service. Cost and quality has a good balance under our evaluation and we are able to bring the analysis into your real outcome. Partner with JCL as your trusted metal stamping supplier in China, contact us and let’s start your sheet metal drawing project instantly with our delicate team.