Surface Cracking or Wrinkling:

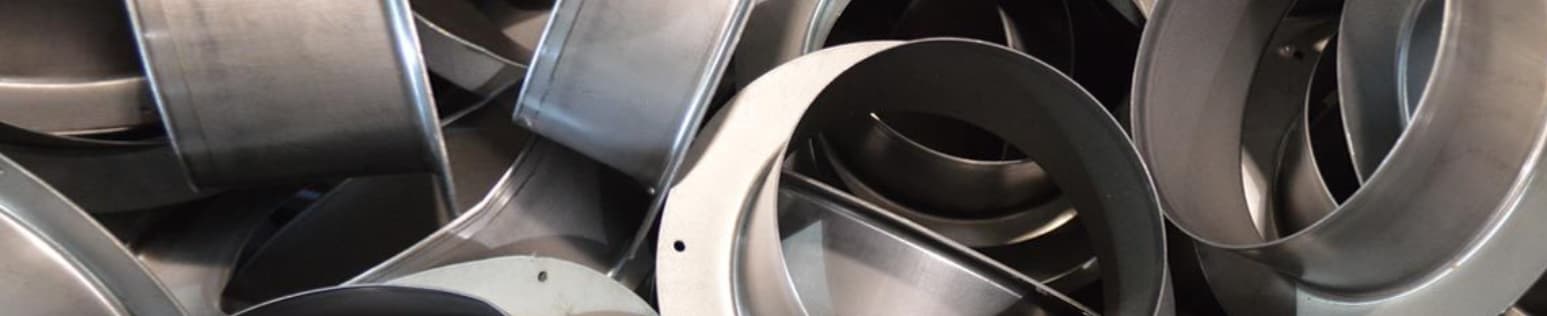

Challenge: Cold sheet metal bending can sometimes lead to surface cracking or wrinkling.

Solution: JCL minimizes cracking by adjusting the deep-drawing parameters and lubricating tooling.

Springback Issues:

Challenge: cold rolled steel may have springback issues.

Solution: JCL compensates for springback by overforming the initial shape or incorporating secondary forming operations.

Tool Wear and Maintenance:

Challenge: Sheet metal bending tools can wear sometimes due to the abrasiveness of cold rolled steel.

Solution: JCL chooses metal bend tool materials with high wear resistance and optimizes them for longer durability. We also lubricate and properly cool our metal to reduce friction and wear.

Tolerance Control:

Challenge: It can be challenging to tolerate tight dimensions in bended sheet.

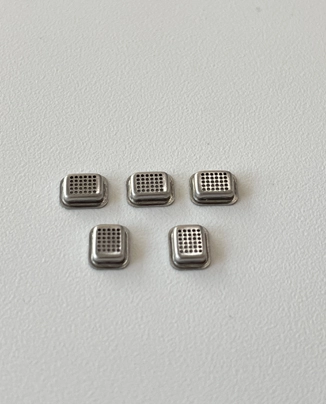

Solution: JCL uses precise tooling and maintains equipment, like the sheet metal punch tool, molds, and parameters to keep tight tolerances.

Material Cost:

Challenge: One obvious cold rolled steel defects would be that it’s more expensive than other materials.

Solution: JCL evaluates the cost-effectiveness for you. We consider the material scrap rates, production efficiency, and the final component's performance to see if it's the appropriate metal for you.

Energy Consumption & Environmental Impact:

Challenge: Cold rolled steel deep drawing processes consume much more energy than other manufacturing methods.

Solution: JCL practices sustainable actions by using recycled steel, optimizing energy efficiency in production processes, and implementing waste reduction measures to minimize the environmental footprint.