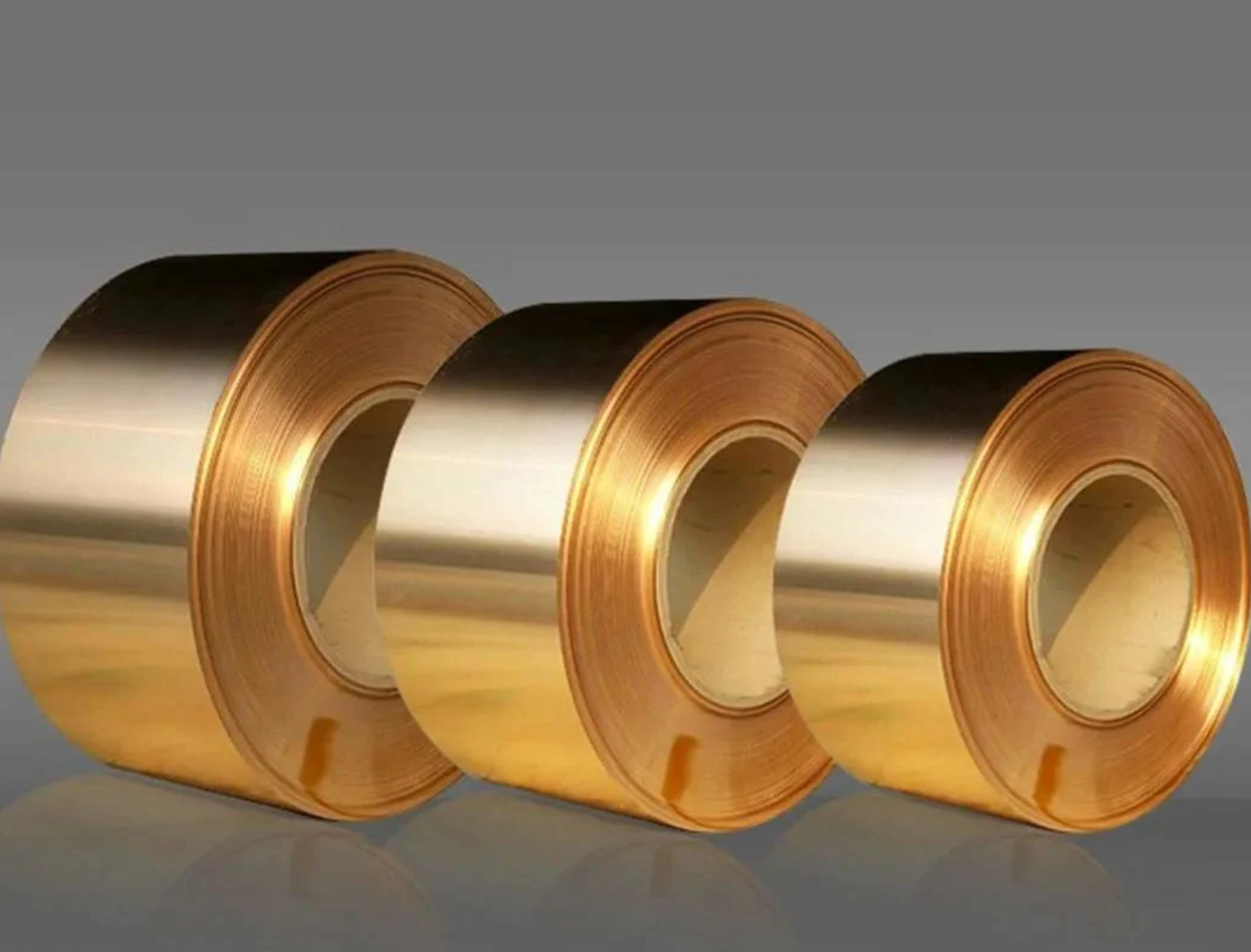

APPLICATIONS OF DEEP DRAWN BRASS STAMPINGS COMPONENTS

Deep Drawing Brass in Automotive Industry

Brass deep-drawing stampings are used in the automotive industry, such as to convey fuel through an injector cup through a fuel line to a fuel rail. They are also used in automotive metal stamping parts, such as automotive oxygen sensors due to their heat and wear resistance.

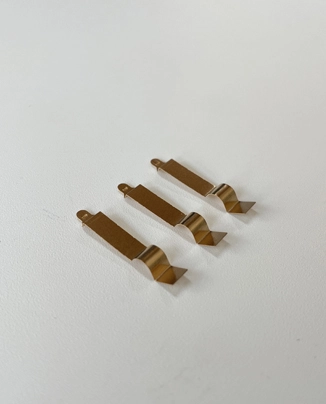

Deep Drawing Brass in Plumbing industry

Deep-drawn brass ferrules are used inside water heaters connecting applications due to their ductile nature to both hot and cold, which allows them to withstand contrasting temperatures. This ductility is also useful in the metal-forming process.

Deep Drawing Brass in Utensils

Deep drawn brass stampings is often used to make utensils in many parts of the world, such as India. Brass utensils help to keep foods warm for longer due to ductility. It is high in zinc, and therefore, cooking on it allows for more zinc to enter your body through food.

Deep Drawing Brass in Doorknobs

Deep drawn brass stampings is commonly used for doorknobs as it is a corrosive-resistant metal and is highly durable. Deep drawn brass stampings is also rust-free and can withstand wear and tear. With proper care and maintenance, brass doorknobs can last a long time.

Deep Drawing Brass in Musical instruments

Deep-drawn brass stampings are also often found in musical instruments. This is due to deep drawn brass being more malleable and corrosion-resistant. It also gives the instruments a shining golden color, which is appealing. You can see deep drawn brass being used for horns or trombones.

Why Choose deep drawn brass stampings

Brass is a standard metal used on many occasions due to its properties. You will see it being used in many industries, such as fishing and plumbing, due to its strength, corrosion, and rust resistance. Its properties and cheap quality make deep drawn brass an easy metal to use, especially due to its accessibility. That is why it is also heavily used for musical instruments, Most student-model flutes are made of brass due to easy availability.

Moreover, it is a versatile metal whose components can be altered depending on where it will be used. For example, “naval brass” (for use under seawater) contains 40% zinc and 1% tin, which reduces zinc’s leaching. For plumbing and pumping workings, any brass components used have to have over 15% zinc to be dezincification-resistant.

BENEFITS of DEEP DRAWN BRASS STAMPINGS PARTS

Deep drawn brass parts are durable and long-lasting

Brass deep drawing component is made from high-quality brass, making it extremely durable and able to withstand wear and tear. It will last a long time, saving you money on replacements in the future.

Deep drawn brass parts of detailed precision

As brass drawing components are made using a mechanical process, they can achieve intricate and detailed precision that may be difficult to obtain using other methods of manufacturing.

Deep drawn brass parts are Cost-effective

Brass is an affordable metal, making the production of brass deep drawing tools cost-effective. It means you can get high-quality products at a competitive price. This is beneficial for both small and large-scale production.

Deep drawn brass parts are ersatile

Brass can be easily shaped, allowing for a variety of shapes and designs to be created. This makes it suitable for a wide range of applications, from automotive to household items.