EN

- Metal Enclosure For Vaporizer

- Sheet Metal Covers For Battery

- Connector Housing

- Screen Frame

- Pen Clip

- Metal Speaker Mesh

- Fabricator for Quality EMI Shielding Parts

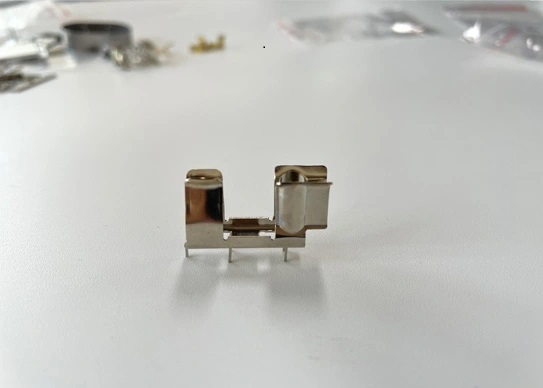

- Stamped Contacts

- Electrical Bracket Box

- Spring Contacts

- Metal Heat Sink

- Terminals and Pins

- Stainless Steel Junction Box Fabrication

- Metal Enclosure for Electronics Fabricator

WHAT ARE YOU LOOKING FOR?