JCL understands that managing secondary operations after deep drawn stamping can be a time-consuming and complex process for our customers. To provide a seamless experience and add value to our stamping services, we offer turnkey solutions that encompass a wide range of secondary operations.

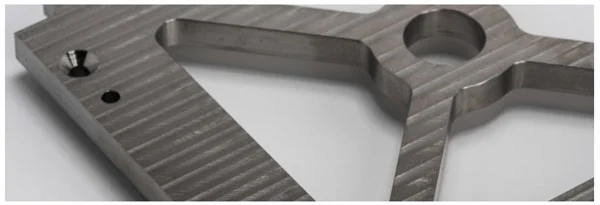

Trimming & Deburring: Trim excess material and remove burrs from the edges of the deep drawn stamped parts, ensuring deep drawn parts have clean and precise edges.

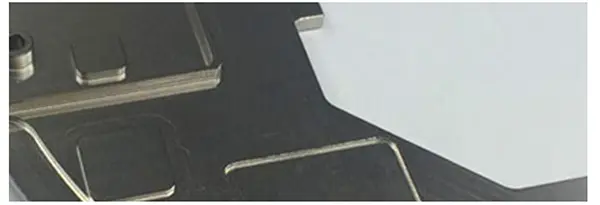

Secondary Forming: If the deep drawn stamped parts require further shaping or forming to achieve the desired final shape or geometry, we have the capabilities to perform bending or forming operations for stamped metal parts.

Surface Finishing: We offer a range of surface finishing treatments to improve the appearance, protect against corrosion. Our metal surface treatment include painting, powder coating, plating, anodizing, or polishing, depending on the specific requirements of our customers.

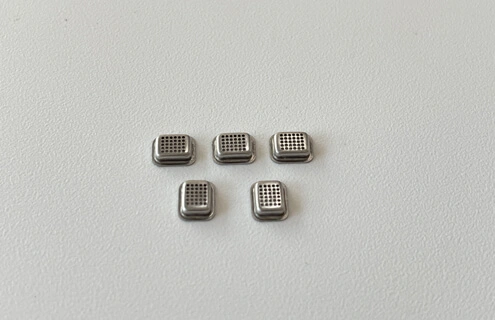

Part Assembly: To simplify the production process and deliver final products to our customers, we offer sheet metal assembly by integrating additional components or subassemblies to create the finished product. Our experienced team ensures full stack assembly service to meet the specifications of the customer's design.

Surface Finishing Technology We Offer

JCL holds a sophisticated line of surface finishing resources localing in pearl river delta areas in guangdong. Collaborating with local suppliers, JCL surface finishing technology is capable of dozens of processes either functional coating or cosmetic looks. JCL surface finishing systems also have a team known very well for finishing expertise especially for stamped parts, from mechanism to actual applications, JCL surface finish operation is able to tackle any finishing problems of formed metals.

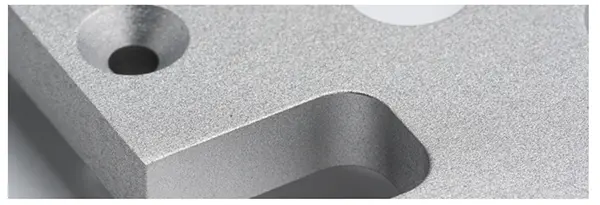

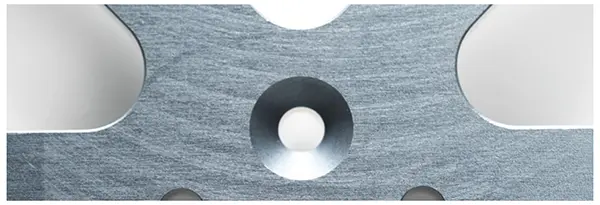

Common Uncoated Surface Finish Operation

Fine polishing

Buffing

Blasting

Tumbling

Brushing

Honing and Lapping

Chemical Etching

Laser Engraving

Common Coated Surface Finish Operation

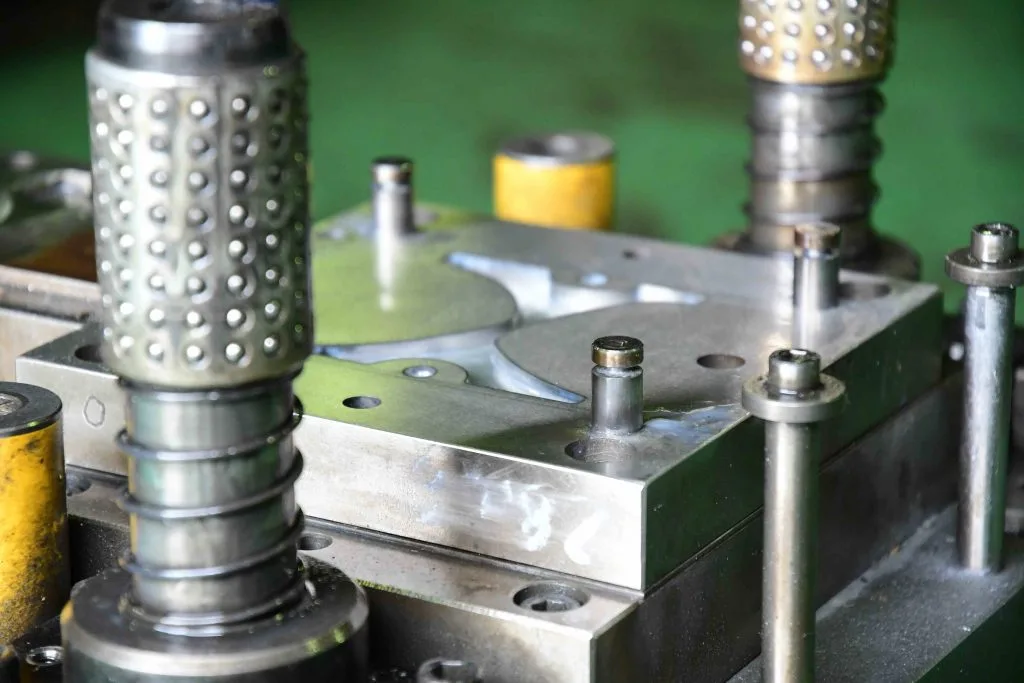

Secondary Operation Equipments

The JCL secondary metal processing team is committed to providing all customers with complete customization capabilities so they can tailor their components to meet the specific demands of their applications. In addition to stamping presses and various tool room machines, our state-of-the-art manufacturing facility contains the following equipments: