How Do Heat Sinks Work?

When electronic devices are operating, electricity passes through them. As a result, these devices generate heat. Controlling the heat and absorbing the heat is essential for saving the electronic gadgets from damage. Heat sinks don't stop the electronic devices from getting excess heat. These are small metal parts that have channels so that air can flow smoothly. It also has a thermal paste or pad, so the heat sink can attach with the electronic part and transfer the heat. This substance aids in the heat's transmission from the component to the heat sink. Once the heat sink absorbs the heat, the channels make the surface large so it can spread out the heat. When heat sinks escape the heat on the air, they assist to cool down electronic devices.

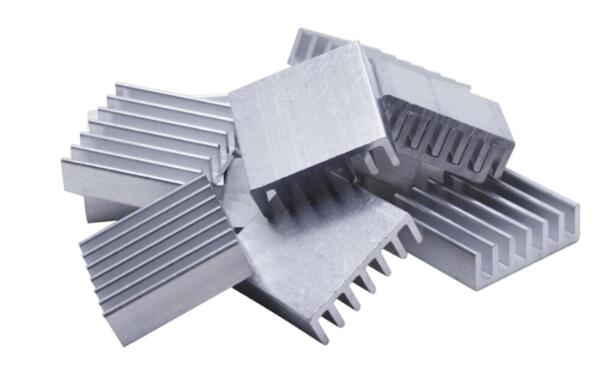

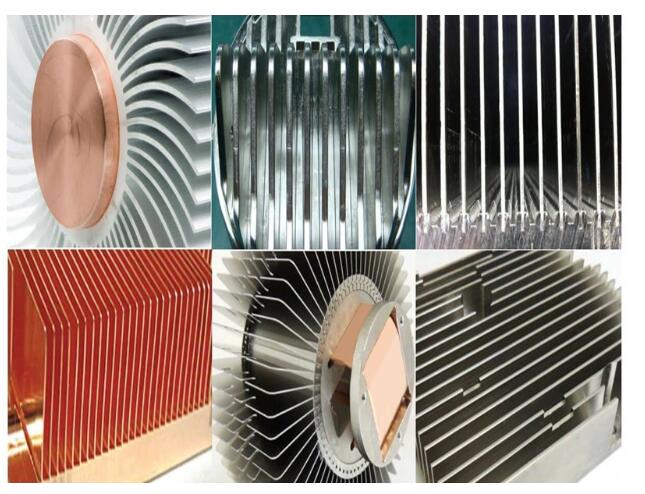

Types of Metal Heat Sinks

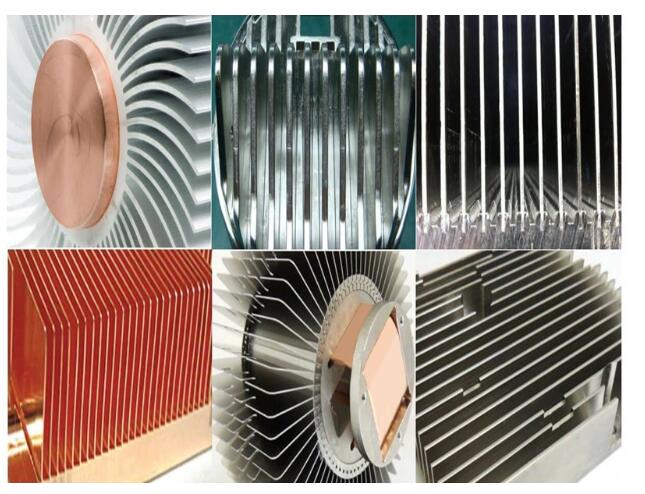

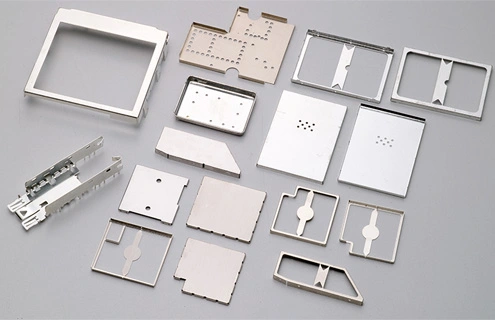

Let’s take a look at the below table to know more about the 6 types of metal heat sinks dependent on the manufacturing process:

Heat Sink Type | Material | Performance | Design Flexibility | Cost | Advantages | Drawbacks |

Extruded | Aluminum | Low to High | Limited by extrusion width | Low | Custom specifications | Dimensional limitations |

Bonded | Aluminum and Copper | Moderate | High | High | Different base and fin materials, improved thermal performance,minimal weight | High cost |

Skived | Copper | Medium to High | High fin density | High | High design flexibility, increased surface area for heat dissipation | High weight, directional sensitivity |

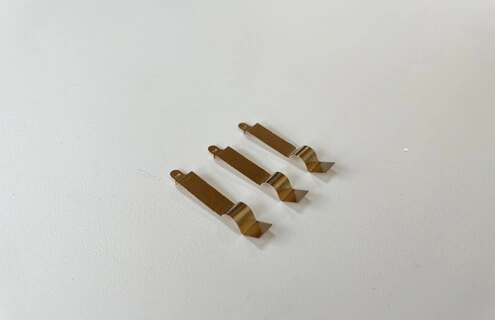

Stamped | Metal | Low | Low | Very Low | Low cost, ease of production automation | Low performance |

Forged | Aluminum or Copper | Medium | Limited | Low | Low cost for high volumes | Limited design capabilities |

CNC Machined | Various | High | High | High | Complex geometries, high thermal conductivity | High cost, long production time |

Application Areas of Heat Sinks

Heat sinks need to be used in every electronic component that can be for overhit. Here are a few application areas:

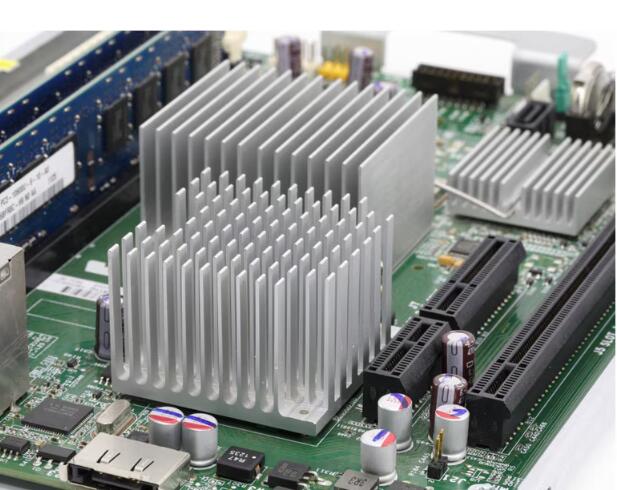

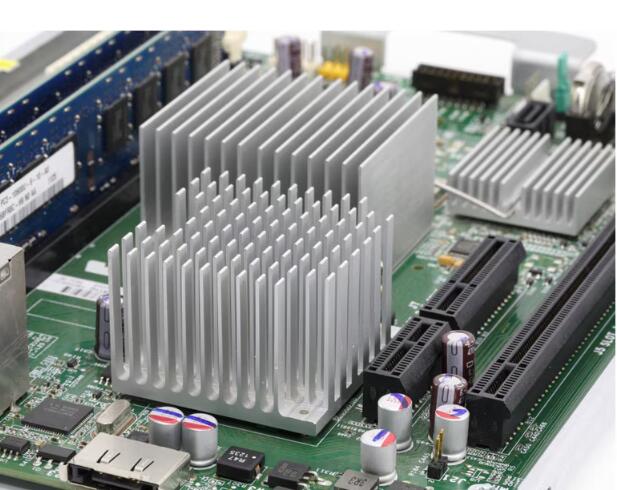

Computer Processors

We use computers in every work now and the CPU is the brain of the computer. When it operates for too long, it gets hot. This excess heat can damage the CPU or hinder its functionality. That’s why CPU’s need metal heat sinks with a fan.

LED Lighting

As LED lights are more energy efficient compared to traditional lights, they don’t generate hits like them. But still LED lights generate some heat, especially in the inner part which needs to be controlled. And using heat sinks in them control this excessive heat.

Telecommunication Equipment

Telecommunication equipment generates a lot of heat while operating. And these hits need immediate dissipation. That’s why equipment like router, cell towers need heat sinks in them. So it can protect these equipment from excessive heat and they can provide communication service without any interruption.

Industrial Machines

Heat sinks are a crucial component for industrial machineries. As these machineries work continuously for manufacturing goods and it needs a good amount of energy to operate, they can build up heat quickly. Overheating not only can create problems for the manufacturing process but also can cause an accident. Preventing such incidents heat sinks must be in their control electronics.

Renewable Energy Systems

Renewable energy systems are very popular these days. Though these systems are environmentally friendly, they still produce waste heat. Especially, the inverters and power units we use in solar panels and air tribunes produce a lot of heat while functioning. Heat sinks utilize in these system so that they can control overheating and increase their efficiency

Factors Affecting Heat Sink Performance

Surface Area: Surface area has a great impact on the performance of metal heat sinks. Because if the surface area is large, it can quickly spread out the heat and coolen the device.

Material: For manufacturing heat sinks, you need to select thermal conductive material. Because these materials help to transfer and absorb heat quickly. Most of the time manufacturers produce heat sinks with aluminum or copper because they are good at dissipating heat.

Heat Sink Design: Heat sink designs also manipulate its performance. The number of fins, its shape and size all needs to be done perfectly for receiving quality service. If heat sink design is efficient, it will not increase the surface but also improve the air flow.

Airflow: Heat sinks require a proper air flow system to pass the hot air. Natural convection is not enough for that. That’s why heat sinks should have a fan or blower for better airflow to increase the heat dissipation.

Thermal Interface: For transferring the heat from the electronic device to the heat sink a thermal interface pad or paste needs to be placed between the component and the base plate. It instantly transfers the waste heat from the device and saves it from damage.

Benefits of JCL’s Custom Metal Stamping Heat Sinks

Thermal Management

Every electronic equipment doesn’t require the same level of thermal management. At JCL, we understand this. That’s why we manufacture our custom metal stamped sinks with different thermal management capacity. We can even customize heat sinks according to your equipment temperature needs.

Lightweight design

Our advanced custom metal stamping process helps us to design and manufacture lightweight metal heat sinks. Our lightweight heat sinks give extraordinary thermal performance without adding extra weight to your device.

Cost-Effectiveness

Our metal stamping process is very cost-effective for high volume product manufacturing. We do bulk production by using our metal stamping process which saves both of your time and money.

Increase Cooling Efficiency

Through our metal stamping process, we maximize the surface area and airflow system so that we can increase the cooling efficiency of our manufactured heat sinks. We ensure that our heat sinks are capable of providing proper cooling so they can protect the devices.