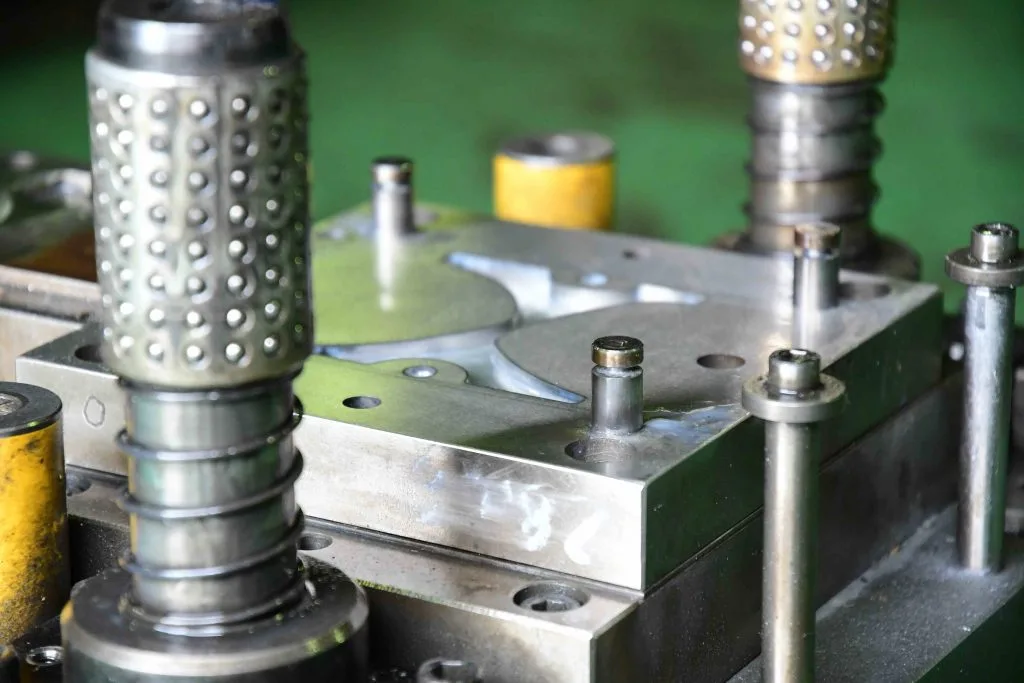

We are committed to delivering the highest level of quality and precision in metal stamping products. As a leading stamping factory, we understand the importance of establishing a robust Quality Management System (QMS) that ensures our customers receive products that meet their exact specifications and exceed their expectations.

EN

- Metal Enclosure For Vaporizer

- Sheet Metal Covers For Battery

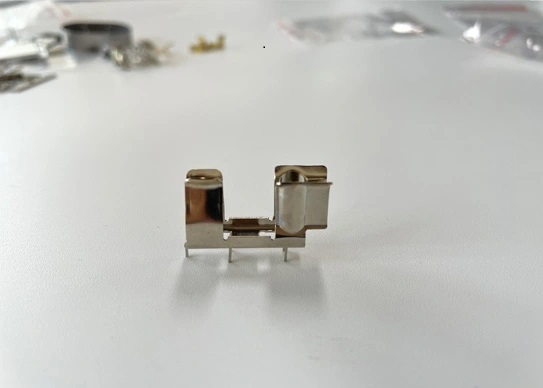

- Connector Housing

- Screen Frame

- Pen Clip

- Metal Speaker Mesh

- Fabricator for Quality EMI Shielding Parts

- Stamped Contacts

- Electrical Bracket Box

- Spring Contacts

- Metal Heat Sink

- Terminals and Pins

- Stainless Steel Junction Box Fabrication

- Metal Enclosure for Electronics Fabricator

WHAT ARE YOU LOOKING FOR?