Metal stamping in the automotive industry has various benefits and because of these, it proves to be a very important aspect of this industry. Some of the aspects that add to the importance are as follows:

Enhanced Vehicle Structural Integrity:

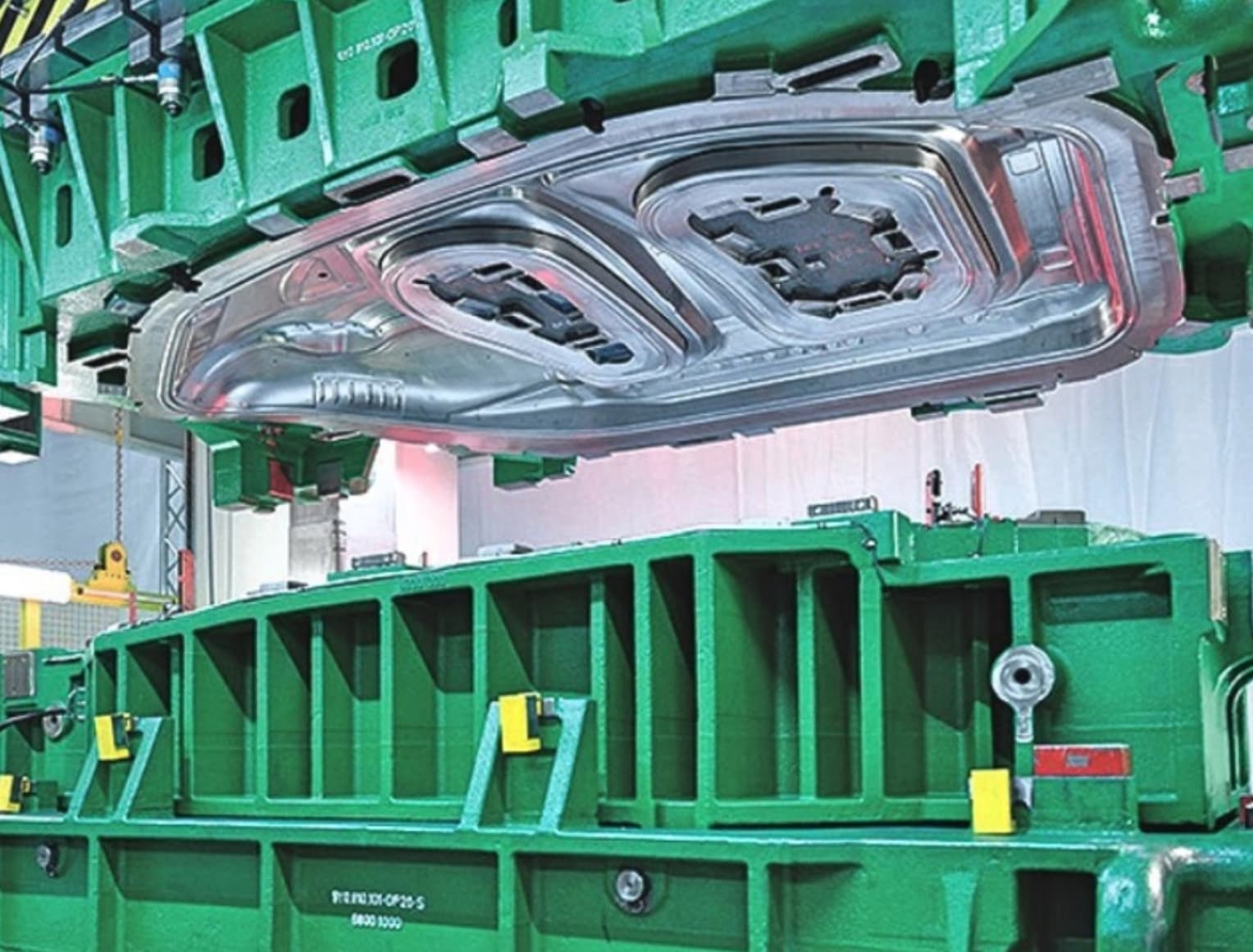

The process of metal stamping is equipped with the ability to provide manufacturing of automobile components that are precise and complex, requiring high structural integrity. It is very important when it comes to constructing chassis, frames, and other important parts of vehicles.

Automotive metal stamping parts can withstand the strain and stress that a vehicle may pass through and ensure durability as well as the safety of the vehicle.

Customization and Design Flexibility:

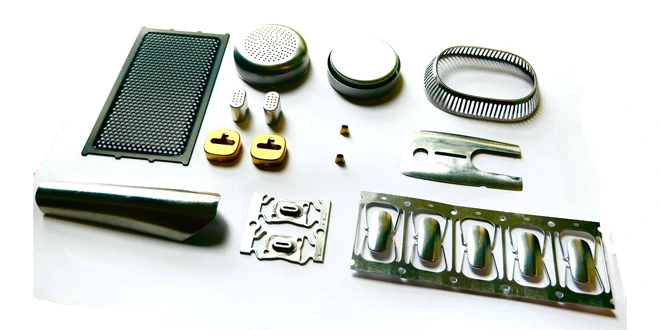

Metal stamping is a very flexible method of manufacturing components. Hence automotive metal stamping parts can be equipped with customization and design flexibility as the innovative and advanced features that evolve now and then can be manufactured easily.

Weight Reduction for Improved Efficiency:

The metal components when manufactured using metal stamping are equipped with lightweight. However, despite being lightweight these parts are equipped with a lot of strength. In the case of electric vehicles it is very important to have a reduced weight so that energy efficiency can be attained.

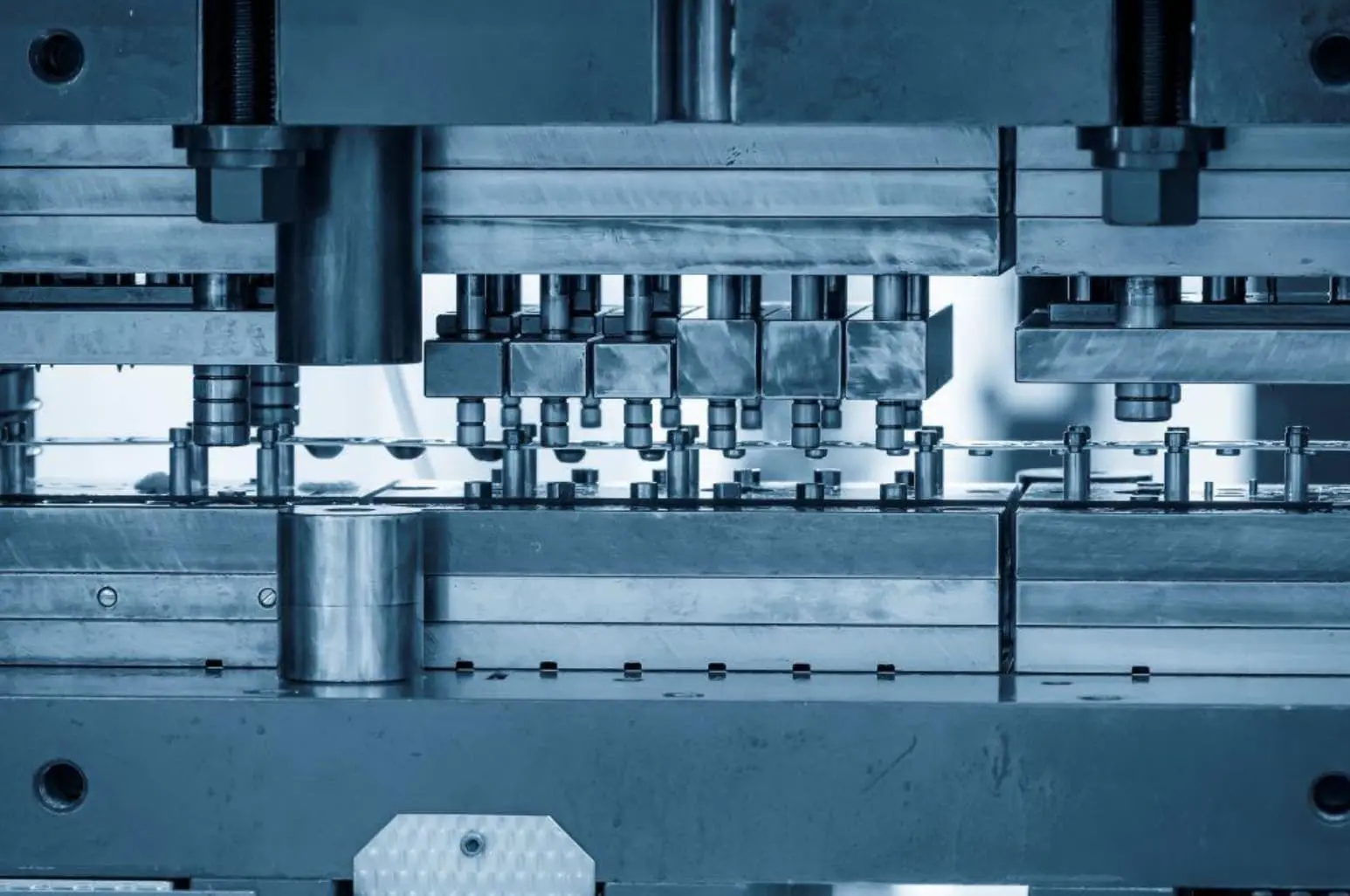

Cost-Effectiveness and Economical Production:

Automotive metal stamping machines are usually equipped with automation which helps in mass production. The automated machine can offer cost savings by increasing and reducing the cost of labor. Hence, a huge volume of metal-stamped components can be manufactured at an affordable price.

Support for Advanced Technologies and Safety Features:

Safety features in an automobile are extremely important and every vehicle needs to meet the safety standards hence the role of metal stamped parts is very crucial here. Metal stamping for automotives helps support advanced technologies to be integrated like sensors and other devices used for communication.